Poultry Processing Industry eTool

Plant-Wide Hazards » Slips, Trips, Falls

Slips, trips, and falls can cause back injuries, strains and sprains, contusions, and fractures.

How do slips, trips, and falls happen?

Falls to same level:

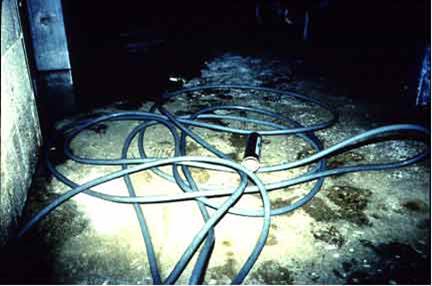

- Floors, platforms and stairways may be slippery from water, blood, or poultry fat and grease. View example.

- Employees may trip over boxes, electrical cords, equipment, or other items that are left in aisles and walkways. View example.

- Floors may be uneven or have depressions or shallow holes or uncovered floor drains that cause employees to trip. View example.

Falls from a higher level to a lower level:

- Stairways may have missing rails or treads, or the riser height may not be uniform. View example.

- Elevated work surfaces may not have guardrails or toeboards.

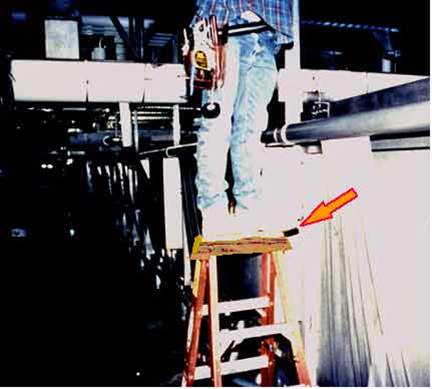

- The distance between rungs on portable ladders may not be uniform, the ladders may not be equipped with non-slip safety feet, or employees may not be trained in the safe use of ladders. View example.

What can employers and employees do to prevent slips, trips, and falls in the workplace?

- Clean up blood and grease as promptly and frequently as possible.

- Provide non-slip surfaces on floors that will be wet.

- Use slip-resistant footwear.

- Keep aisles and passageways clear of obstructions and tripping hazards.

- Make sure aisles are wide enough for the intended use.

- Make sure stairs have proper handrails, that treads and risers are maintained, and that treads have a slip-resistant surface.

- Make sure elevated storage and work surfaces have guardrails, toeboards, and a permanent means of access.

- Make sure that floor drains are covered by grates.

- Maintain ladders in good condition, with uniformly-spaced rungs and non-slip safety feet.

- Train employees in the safe use of ladders.

Specific OSHA Requirements

OSHA Requirements for the prevention of slips, trips, and falls are contained in 29 CFR 1910 Subpart D, Walking-working surfaces. The sections included in this subpart are (see Walking and Working Surfaces):

- Definitions,

- General requirements (including requirements for housekeeping),

- Guarding floor and wall openings and holes,

- Fixed industrial stairs,

- Portable wood ladders,

- Portable metal ladders,

- Fixed ladders,

- Safety requirements for scaffolding,

- Manually propelled mobile ladder stands and scaffolds (towers), and

- Other working surfaces.

Additional explanation of the OSHA requirements for walking-working surfaces can be found in OSHA's Small Business Handbook. OSHA Publication 2209, (2024) [Español OSHA Publication 4261, (2024)].

29 CFR 1910 Subpart I, Personal protective equipment is also applicable as it applies to the use of non-slip safety footwear. See especially:

Another useful OSHA publication is:

- Stairways and Ladders: A Guide to OSHA Rules (PDF). OSHA Publication 3124, (2003).

NOTE: Employers in states with state-run safety and health plans should check with their state agency. Their state may enforce standards that, while "as effective as federal standards," may not be identical to the federal requirements.

Walking and Working Surfaces

- Housekeeping:

- Clean, orderly, in sanitary condition

- Floors clean and, so far as possible, dry

- Where wet processes used, drainage maintained and gratings, mats, or raised platforms provided

- Floors and passageways free from protruding nails, splinters, loose nails, etc..

- Aisles and passageways:

- Clear and unobstructed

- Permanent aisles and passageways marked

- Of sufficient width where mechanical handling equipment used

- Covers and guardrails provided to protect personnel from hazards of open pits, tanked, ditches, etc.

- Floor loading protection

- Limits posted.

- No load on roof or floor greater than approved.

- Stairway and ladderway floor openings

- Standard railing with standard toeboard except at entrance side, or

- Hinged cover and removable standard railings if infrequently used.

- Hatchway and chute floor openings

- Hinged floor opening cover with standard railing to leave only 1 exposed side, or

- Removable railing with toeboard on not more than 2 sides, with fixed railing and toeboards on all other sides.

- Floor holes into which persons can accidentally walk

- Standard railing/toeboard on all exposed sides, or

- Hinged floor cover - when cover off, hole either attended or protected with removable standard railing

- Standard railing

- Top rail

- Intermediate rail

- Posts

- Vertical height of 42 inches

- Constructed to withstand a load of 200 pounds in any direction at any point on top rail

- Stair railing

- Vertical height of 30-34 inches from forward edge of tread

Toeboards

- Must be used with railings protecting floor openings, platforms, scaffolds, etc., whenever

- Persons can pass beneath

- There is moving machinery

- There is equipment with which falling materials could cause a hazard

- Must be at least 4 inches in height and made of any substantial material

- Flights with 4 or more risers must have:

- Standard railing on all open sides

- Handrails on at least 1 side of enclosed stairs

- Must have uniform riser height and tread width

- Must have a minimum width of 22 inches

- Must be provided where:

- Operations necessitate regular travel between levels

- Routine access to operating equipment is needed

- Daily, or at each shift, access to levels is needed where such work may expose employees to harmful substances or for which carrying tools or equipment by hand is normally required

- Spiral strairways permitted only for special conditions

- Inspected frequently; defective ladders must be withdrawn from service and tagged "Dangerous, Do Not Use"

- Stepladders - metal spreader or locking device

- Non self-supporting ladders

- Erected on sound base and placed to prevent slipping

- Base of ladder placed a distance from wall 1/2 of length of ladder

- Ladder used to gain access to a roof - top should extend at least 3 feet above point of contact

- Rungs

- Minimum diameter 3/4 inch (metal) or 1-1/8 inch (wood)

- 16 inches wide

- Uniformly spaced no more than 12 inches apart

- Cages, wells, or ladder safety devices for ladders affixed to towers, water tanks, or chimneys

- Provided on all ladders over 20 feet

- Landing platforms every 30 feet, unless there is no cage - then every 20 feet

- Tops of cages to extend 42 inches above the top of landing, unless other protection provided, and bottoms to 7-8 feet above base of ladder

- Side rails to extend 3-1/2 feet above landing