Cranes & Derricks in Construction

Frequently Asked Questions - Revised July 18, 2016

IMPORTANT:

On September 26, 2014, OSHA published a final rule that extends the deadline for crane operator certification in the cranes standard at 29 CFR 1926.1427 for 3 years, to November 10, 2017 (published in the Federal Register). The final rule also extends the employer's duty to ensure that operators are competent to operate the crane safely for the same three year period. During this extension, OSHA will address operator qualification through additional rulemaking. OSHA will provide updated information about the crane operator certification and qualification requirements as it becomes available on OSHA's Cranes & Derricks in Construction page.

PLEASE NOTE:

OSHA is working on proposed amendments to address some other issues in the cranes standard, including clarifying the scope of what forklifts and multi-purpose equipment are included in and excluded from the cranes standard, as well as the unavailability of Nationally Recognized Testing Laboratory (NRTL) approved proximity alarms and insulating links for construction work in proximity to power lines.

General Overview | State Plan Impact | Operator Certification/Qualification | Scope | Forklifts | Material Delivery | Ground Conditions | Power Lines

Inspections | Rigger Qualifications | Signal Person Qualifications | Equipment Issues | Cranes Standard Basics and Background

General Overview

Subpart CC of 29 CFR Part 1926 (§1926.1400 et seq.), Cranes and Derricks in Construction ("cranes standard"), applies to cranes and derricks when used in construction activities. Section 1926.1400—Scope of the cranes standard sets forth the types of equipment that are included in the cranes standard and excludes from the standard certain types of equipment and cranes engaged in certain types of activities.

Subpart CC of 29 CFR Part 1926 (§1926.1400 et seq.), Cranes and Derricks in Construction ("cranes standard"), applies to cranes and derricks when used in demolition and underground construction work.

Employers who use cranes and derricks in construction work must comply with the cranes standard. In addition, other employers on construction sites where cranes and derricks are used are responsible for ensuring that their employees are not exposed to hazards associated with cranes, and, therefore, they need to address the requirements of the standard that may affect their employees. Crane lessors who provide operators and/or maintenance personnel with the equipment have duties under the cranes standard. The cranes standard also explicitly establishes certain tasks for some entities or individuals. Some examples are listed below. Note that employers, not employees, are responsible for meeting the requirements of OSHA's standards, including the cranes standard.

- Controlling contractors are responsible for ensuring that ground conditions are sufficient for the crane or other covered equipment to be assembled. (See §1926.1402(c)).

- Utility owner/operators must provide voltage information for work in proximity to power lines in certain circumstances under §§1926.1407-1409, and employers must consult with utility owner/operators in order to perform work in very close proximity to power lines under §1926.1410. (See §§1926.1407-1410).

- Crane inspector duties are contained in §1926.1412. Inspections of modified equipment, repaired or adjusted equipment, post-assembly, annual inspections, severe-service and equipment not in regular use must be performed by a qualified person as defined in §1926.1401. Shift and monthly inspections must be performed by a competent person as defined in §1926.1401.

- The Assembly /Disassembly Director has specific duties outlined in §§1926.1402-1404 and §1926.1407 for assembly or disassembly in proximity to power lines.

- The employer must assure that signal persons meet the qualification requirements in §1926.1428. The standard outlines signal persons' duties in §§1926.1419-1422.

- Until operator certification goes into effect, under §1926.1427 the employer has a duty to ensure that the crane operator is qualified to operate the equipment under §1926.1427(k)(2).

State Plan Impact

Yes. Twenty-two states or territories currently operate their own OSHA-approved state plans (covering private and public sector employees), and five additional states and one territory (Connecticut, Illinois, Maine, New Jersey, New York and the Virgin Islands) operate plans that cover public sector employees only. The OSHA-approved state-run safety and health plans must be "at least as effective as" the Federal OSHA program. Most state plans adopt standards identical to federal standards. However, state plans have the option of promulgating more stringent standards or standards covering hazards not addressed by Federal OSHA standards.

Operator Certification/Qualification

IMPORTANT:

On September 26, 2014, OSHA published a final rule that extends the deadline for crane operator certification in the cranes standard at 29 CFR 1926.1427 for 3 years, to November 10, 2017 (published in the Federal Register). The final rule also extends the employer's duty to ensure that operators are competent to operate the crane safely for the same three year period. During this extension, OSHA will address operator qualification through additional rulemaking. OSHA will provide updated information about the crane operator certification and qualification requirements as it becomes available on OSHA's Cranes & Derricks in Construction page.

Employers must ensure that equipment operators are competent through training and experience to operate the equipment safely (see 29 CFR 1926.1427(k)(2)). If an employee assigned to operate a crane does not have the required knowledge or ability to operate the equipment safely, the employer must train that employee before allowing him or her to operate the equipment and must evaluate the operator to confirm that he/she understands the information provided in the training (see 29 CFR 1926.1427(f) training requirements).

The answer depends on whether the licensing criteria meets the minimum requirements ("federal floor") in 29 CFR 1926.1427(e)(2) and (j). If a state or local jurisdiction has a licensing program that meets the federal floor, OSHA requires the employer to ensure that all operators operating within that jurisdiction are licensed by that state or local jurisdiction, unless they are qualified by the U.S. Military (see §1926.1427(a)(1)). This requirement went into effect in November 2010. Note, however, that the crane standard's operator certification requirements do not supersede state or local licensing laws. If the licensing program does not meet the federal floor, OSHA does not require operators to be licensed in accordance with that program, although the operator may still be subject to action by the state or local authority for failure to comply with its requirements.

Initially, states or local governments are responsible for determining if a state or local operator certification program meets the requirements of 29 CFR 1926.1427(e)(2)(i-ii) (see §1926.1427(e)(2)(iii)). OSHA does not require compliance with a state or local licensing requirement unless the state or local authority that oversees the licensing department/office assesses that program and determines that it meets the minimum requirements in §1926.1427(e)(2)(i) and (ii), including satisfying the substantive testing criteria of §1926.1427(j) through written and practical tests and providing testing procedures for re-licensing. OSHA does not intend to require compliance with a state or local licensing requirement absent a public statement by the authority with oversight responsibility for the licensing office that the licensing program meets OSHA's minimum requirements and the reason for that determination. However, OSHA has the final authority in determining that the program meets minimum OSHA requirements.

No. This option is only available to civilian and uniformed employees of the Department of Defense. When the operator certification requirements are in effect, private contractors must use one of the other options for operator certification/qualification available under 29 CFR 1926.1427.

No. OSHA does not evaluate or approve crane operator training courses or crane operator certification testing bodies. Under the cranes standard, operator certification testing bodies must be accredited by a nationally recognized accrediting agency (29 CFR 1926.1427(b)(1)(i)). Currently the American National Standards Institute (ANSI) and the National Commission for Certifying Agencies (NCCA) are the two organizations that OSHA has identified as nationally recognized accrediting agencies.

Scope

Yes, digger derricks used in construction are generally covered by the cranes standard, except digger derricks used in power distribution and transmission work covered by 29 CFR 1926 Subpart V are exempted from the standard. In addition, digger derricks used in telecommunication work are exempted from the requirements of the cranes standard provided that the following requirements are met: (1) the digger derricks are used for augering holes for poles, placing or removing the poles, or handling associated materials, and (2) the employer must comply with §1910.268 telecommunication work requirements.

No. OSHA has determined that water well drilling equipment and activities, like oil and gas drilling, are covered by applicable requirements of 29 CFR Part 1910. (See 2/26/82 Interpretation/Memorandum to Gilbert J. Saulter).

The scope of the cranes standard at 29 CFR 1926.1400(a) is limited to "power-operated equipment, when used in construction, that can hoist, lower, and horizontally move a suspended load." OSHA specifically notes in the standard that "a crane on a monorail" is included within the scope of the new standard. A hoist mechanism on a mast climbing platform that is attached to a monorail and can lift a suspended load vertically up from the ground to the scaffold and horizontally along the monorail is covered by the cranes and derricks in construction standard to the extent it is "powered-equipment used in construction." If the only horizontal movement of the hoist is by hand, without the assistance of any motor or other powered-equipment, the hoist would not constitute powered-equipment under §1926.1400(a), and the equipment would be subject to §1926.552—Material hoists, personnel hoists, and elevators, rather than the cranes standard. (See 7/8/11 Interpretation Letter to Clint Bridges).

No. OSHA's cranes standard covers hoisting equipment used in conjunction with a construction activity. Although the act of excavating a grave would be considered a construction activity, the placement of a burial vault in the grave is not a form of construction. There are no connections, either mechanical or electrical, made from a burial vault to other objects or structures. Once the burial vault is placed in the ground, there is no further construction work performed to build onto or otherwise alter its structure. During the placement process, the burial vault is not arranged in a sequence for further hoisting, an action that indicates construction crane activity. (See 2/26/13 Interpretation Letter to Thomas Monahan).

Generally, yes. In contrast to the placement of burial vaults, the hoisting of tanks and precast components/structural members, such as sewer pipes and electric vaults, into an excavation would be considered a construction activity because those components/members are positioned by a crane as part of a larger operation, system, or structure, and these objects are then connected to other structures, systems, or foundations. The use of a crane in such situations is part of a construction-related operation and would therefore fall within the requirements of the cranes standard. (See 2/26/13 Interpretation Letter to Thomas Monahan).

Yes. The scope of the cranes standard at 29 CFR 1926.1400(a) is limited to construction equipment that can "hoist, lower, and horizontally move a suspended load," and it includes such construction equipment with dragline attachments. As OSHA noted in the preamble to the final rule, most of the operational characteristics and hazards of the crane remain the same if a dragline attachment is in use, and OSHA wanted to avoid situations where the equipment moves in and out of the standard's scope depending on the equipment attachments. (See the cranes standard's preamble in the Federal Register at 75 FR 47906, 47923 (Aug. 9, 2010), as well as OSHA's 10/3/12 Congressional correspondence with the Honorable Charles Boustany, Jr.).

No. An employee only delivering equipment to a construction site would not be engaged in a construction activity when, for example, the employee merely moves the equipment on and off the transportation trailer at access roads or areas adjacent to the construction site. Under the general industry standard at 29 CFR 1910.180(b)(3), the employee designated to move the crane on and off the trailer must be qualified to operate the crane. In general, a rental company employee must meet the requirements of the construction cranes standard when the employee performs activities specified in the cranes standard such as assembly/disassembly, hoisting loads, or traveling from place to place on the worksite.

Forklifts

Equipment that is designed to function as both a crane and a forklift would be considered multi-purpose equipment and covered by the cranes standard when configured to hoist and lower (by means of a winch or hook) and horizontally move a suspended load. However, OSHA intends to propose amendments to the cranes standard which will clarify that forklifts are excluded from coverage by the cranes standard unless they are equipped with a boom/jib and a hoist and used like a crane.

Material Delivery

Generally, no. The cranes standard does not apply when construction materials are delivered from the flatbed to the ground at a construction site and the crane is not used to arrange those materials in a particular sequence for hoisting. This is considered a “general industry” activity covered by applicable requirements of 29 CFR Part 1910.

Moving materials onto a structure being erected is a construction activity. However, 29 CFR 1926.1400(c)(17)(ii) expressly excludes from the requirements of the cranes standard the delivery of certain materials to structures on construction sites using an articulating/knuckle-boom crane if all requirements of this limited exclusion are met. These requirements include:

- goods delivered directly to the structure must be building supply sheet goods or building supply packaged materials, including, but not limited to, sheets of sheet rock, sheets of plywood, bags of cement, sheets or packages of roofing shingles, and rolls of roofing felt;

- the cradle/fork must be attached to the boom; and

- the truck must be equipped with a properly functioning automatic overload prevention device.

In situations where any of these requirements are not satisfied, or where equipment is used to hoist and hold any materials in support of their application or installation, articulating/knuckle-boom equipment does not fall under the limited exemption in §1926.1400(c)(17)(ii) and must comply with the cranes standard. Likewise, the use of articulating/knuckle-boom cranes to deliver materials onto a structure is also covered by the cranes standard when delivering materials such as steel joists, beams, columns, steel decking, or components of systems engineered metal buildings; precast concrete members or panels; roof trusses (wooden, cold formed metal, steel or other material); prefabricated building sections such as but not limited to, floor panels, wall panels, roof panels, or roof structures; or materials similar to these.

When the articulating/knuckle-boom truck equipment described above is engaged in construction activity by delivering materials to a structure, but is excluded from the cranes standard because it meets the requirements in 29 CFR 1926.1400(c)(17)(i), the equipment is subject to applicable construction standards in subpart O, such as 29 CFR 1926.600(a)(6), which governs work in proximity to power lines.

Ground Conditions

Yes, assuming that the general contractor is the controlling entity or employer described in 29 CFR 1926.1402(d), which would normally be the case, the cranes standard requires the general contractor to improve the site. It is ultimately the controlling entity's responsibility to make sure sufficient improvements to ground conditions are made for the crane to be assembled or used within the requirements of §1926.1402(b). Section 1926.1402(c)(1) requires that the controlling entity must ensure that ground preparations necessary to meet the requirements in paragraph (b) of this section are provided. (See 10/1/12 Interpretation Letter to Richard Marshall).

OSHA requires the controlling entity to be responsible for ground conditions because the controlling entity has the authority to improve ground conditions and is in the best position to ensure that the conditions are sufficient. The cranes standard does not include a specific duration on this duty. Thus, the controlling entity must meet this obligation whenever the crane is set-up or used, and that duty continues for the duration of the construction activity, including set-up needed for assembly and disassembly, as well as for hoisting operations and movement of the crane around the site. Because construction worksite conditions are always subject to change, §1926.1412(d)(1)(x) of the cranes standard requires a competent person to inspect the ground conditions each shift to ensure proper support of the crane. In addition, §1926.1402(e) requires that the operator or assembly/disassembly director notify the controlling entity of inadequate ground conditions. Therefore, the controlling entity must provide for preparations whenever they are needed to address changes in ground conditions that would make its support of the crane inadequate, even if the crane has not moved on the site. (See 10/1/12 Interpretation Letter to Richard Marshall).

Power Lines

The cranes standard at 29 CFR §1926.1407(e) states: “Voltage information. Where Option (3) of this section is used, the utility owner/operator of the power lines must provide the requested voltage information within two working days of the employer's request.” Thus, §1926.1407(e) allows a utility owner/operator two working days to provide the requested information. For the purposes of this provision, working days include all calendar days except weekends and holidays. (See the preamble to the cranes standard in the Federal Register at 75 FR 47951). For example, if an electric utility receives a request for voltage information on one of its distribution lines on a Friday, it will have until the end of the business day on the following Tuesday to provide the necessary information (assuming there are no holidays in between). (See 10/13/11 Interpretation Letter to Charles Kelly).

No. The cranes standard does not require utility companies to deenergize power lines. The provisions of §1926.1408 (Power Line Safety) allow deenergization as one option for employee protection from electrical hazards of power lines. Employers choosing this option must not proceed with this option if the electric utility does not deenergize the power line. (See 10/13/11 Interpretation Letter to Charles Kelly).

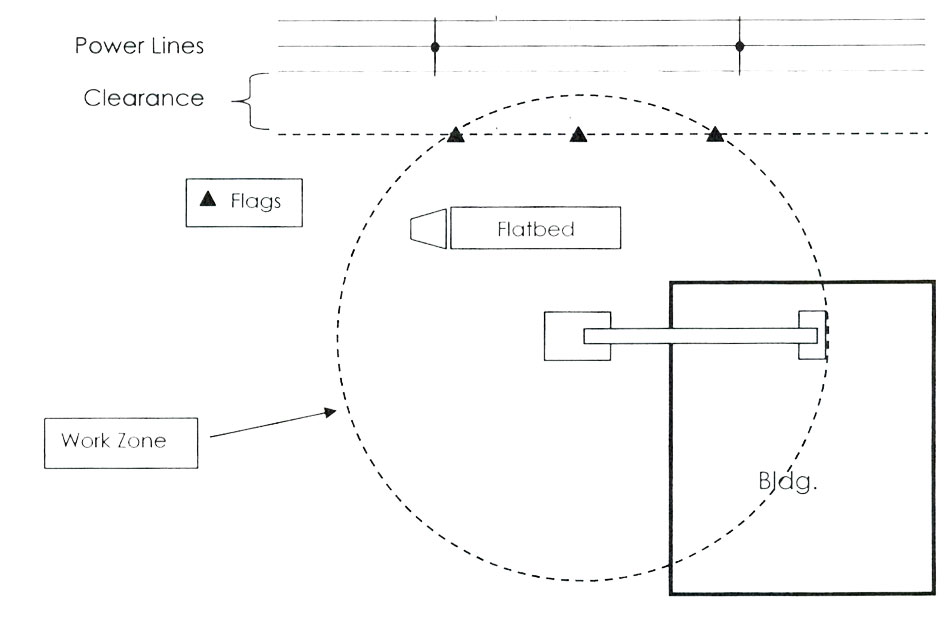

Yes, the employer is in compliance with 29 CFR 1926.1408 as long as (1) the crane operator is prohibited from operating the crane outside of the demarcated work zone, and (2) the flags used to demarcated the work zone are close enough to each other and extend far enough along the demarcated boundary line that the operator is able to use them to judge whether the equipment remains within the demarcated boundary line. This type of demarcation—a line of flags parallel to the power line and located at least the minimum clearance distance from the power line—is one type of demarcation that is adequate under the standard at §1926.1408(a)(1). If the demarcated boundary line is located at least the minimum clearance distance required by the standard from the power line, no further precautions are needed. However, if the demarcated work zone is located closer than the minimum clearance distance required by the standard, then the employer must either ensure that the power line is deenergized and grounded, or the employer must implement measures specified in §1926.1408(b). (See 3/29/12 Interpretation Letter to Walter Tucker, Jr.).

No. The examples below demonstrate other flag configurations which could meet the demarcation requirements in §1926.1408(a)(1)(i). To meet these requirements, the flags must be close enough to each other and extend far enough along a demarcated boundary line that the operator can use them to judge whether the equipment remains within the demarcated boundary line. As stated in the preamble to the cranes standard, one way a work zone can be defined is by demarcating boundaries “[t]o the left and right of the operator, to limit the lateral movement of the boom.” (See the preamble to the cranes standard in the Federal Register at 75 FR 47952). The two flags in example 2 demarcate the work zone to the left and right of the operator and enable the operator to limit lateral movement of the boom so it stays the minimum clearance distance from the power line. As long as the operator understands that the boom must not be swung to the left of the flag on the building or to the right of the other flag, the minimum clearance distance will be maintained, and additional flags are not needed. (See 3/29/12 Interpretation Letter to Walter Tucker, Jr.).

Under §1926.1408(a)(2), an employer must “[d]etermine whether any part of the equipment, load line or load (including rigging and lifting accessories), if operated up to the equipment's maximum working radius in the work zone, could get closer than 20 feet to a power line. If so, the employer must meet the requirements in Option (1), Option (2), or Option (3).” OSHA stated in its preamble to the final rule that “if a demarcated boundary is used, the assessment must be made with the assumption that the crane would be operated up to that boundary.” (See the preamble to the cranes standard in the Federal Register at 75 FR 47952). Therefore, if the demarcated boundary is 20 feet from the power line, the employer has satisfied the minimum clearance distance required by the standard. Likewise, if the demarcated boundary is closer than 20 feet to the power line, but the employer determines the line's voltage and the demarcated boundary meets the minimum approach distance requirements in Table A (for example, 10 feet for voltages up to 50 KV), then the employer has satisfied the minimum clearance distance required by the standard as well. However, if the distance between the demarcated boundary line and the power line is less than 20 feet and less than the Table A distance, then the employer must either ensure that the power line is deenergized and grounded, or the employer must implement measures specified in §1926.1408(b). (See 3/29/12 Interpretation Letter to Walter Tucker, Jr.).

OSHA has issued a memorandum containing its current enforcement policy for the use of proximity alarms or insulating links that are not NRTL approved. (See 3/31/14 Temporary Enforcement Policy for Proximity Alarm and Insulating Link Use with Cranes and Derricks in Construction Memorandum). Because no proximity alarms or insulating links have been NRTL approved, these devices may not be used as safety measures to meet the requirements in 29 CFR 1926.1407, §1926.1408 or §1926.1409. However, under OSHA's temporary enforcement policy, insulating links which are not NRTL approved are permitted in §1926.1410 regardless of the date of manufacture, but they must be used in conjunction with the temporary alternative measures contained in §1926.1410(d)(4)(iv), which require all employees, excluding equipment operators located on the equipment, to be “insulated or guarded from the equipment, the load line, and the load through an additional means other than” the insulating link, such as insulating gloves that are rated for the voltage involved. OSHA has also presented this issue to ACCSH and intends to propose amendments to the cranes standard which will address the unavailability of NRTL approved proximity alarms and insulating links.

The cranes standard includes training requirements for work in proximity to power lines, including the requirement that each employer must train each operator and crew assigned to work with equipment on the procedures to be followed to properly ground equipment and the limitations of grounding (29 CFR 1926.1408(g)(1)(v)). However, for employees that are not tasked to ground the crane, §1926.1408(g)(1)(v) only requires training with respect to the recognition of hazards associated with ungrounded cranes. Conditions that each crew member should be able to at least recognize include:

- Whether the crane appears to be grounded;

- How the crane is grounded to the extent that they will know how not to compromise those engineering controls during the performance of their work;

- That grounding alone will not eliminate electrical hazards, whether from induction or contact; and

- That a minimum clearance distance from the transmitter/communication tower must be maintained.

In contrast, training to ensure knowledge of more advance electrical concepts, such as induction, step, and touch potentials is not required for compliance with §1926.1408(g)(1)(v).

Inspections

A variety of inspections are required to ensure that equipment is in safe operating condition. These include, but are not limited to:

- Shift inspections for all equipment;

- Monthly inspections for all equipment;

- Annual inspections for all equipment;

- Shift, monthly, and annual inspections for all wire rope;

- Post-assembly inspections upon completion of assembly;

- Pre-erection inspections of tower cranes;

- Inspections of modified or repaired/adjusted equipment;

- Four-year inspections of the internal vessel/flotation device for floating cranes/derricks.

No. Crane inspectors are not required to be certified. They must, however, possess a level of expertise that is based on the complexity and type of inspections they perform (competent). For more complex inspections (such as an annual inspection or an inspection after the completion of a modification or repair), the inspector must be qualified through possession of a recognized degree, certificate, or professional standing; or by extensive knowledge, training, and experience, and be able to successfully demonstrate the ability to solve/resolve problems related to the inspection of cranes and related activities (qualified). (See also 3/13/12 Interpretation Letter to Kira Henschel)

In response to public comments and the results of several crane investigations, OSHA now requires a pre-erection inspection for tower cranes to enable the employer to identify crane components that have been damaged when transported to the worksite and prevent damaged components from being used to erect the crane.

Rigger Qualifications

A qualified rigger is a rigger who meets the criteria for a qualified person. A qualified rigger must therefore:

- possess a recognized degree, certificate, or professional standing, or have extensive knowledge, training, and experience, and

- successfully demonstrate the ability to solve problems related to rigging loads.

A qualified rigger must be able to properly rig the load for a particular job. He or she need not be qualified to do every type of rigging job. Each load that requires rigging has unique properties that can range from the simple to the complex. However, previous experiences does not automatically qualify the rigger to rig unstable, unusually heavy, or eccentric loads that may require a tandem lift, multiple lifts, or use of custom rigging equipment. In essence, employers must make sure that the person can do the rigging work needed for the exact types of loads and lifts for a particular job with the equipment and rigging that will be used for that job. (See 1/9/12 Interpretation Letter to William Irwin, Jr.).

A certified operator does not necessarily meet the requirements of a qualified rigger. The person designated as the qualified rigger must have the ability to properly rig the load for a particular job. A certified or qualified operator may meet the requirements of a qualified rigger, depending on the operator's knowledge and experience with rigging. In general, the qualifications of a rigger and an equipment operator are not considered one in the same.

No. Riggers do not have to be certified by an accredited organization or assessed by a third party. Employers may choose to use a third party entity to assess the qualifications of the rigger candidate, but they are not required to do so. (See 1/9/12 Interpretation Letter to William Irwin, Jr.).

No. The employer must determine the qualifications of the rigger as applicable to the hoisting job to be performed. While documentation, such as a card from an assessing organization indicating that the individual has demonstrated specified skills, could serve as evidence of a rigger's qualifications, the cranes standard does not require that a rigger carry such documentation.

No. There is no requirement in the cranes standard that requires a qualified rigger to be evaluated by a qualified evaluator. The employer must determine the qualifications of the rigger as applicable to the hoisting job to be performed. For further information regarding rigger qualifications, refer to related fact sheets.

Signal Person Qualifications

A signal person must:

- Know and understand the type of signals used;

- Be competent in the application of the type of signals used;

- Have a basic understanding of equipment operation and limitations, including the crane dynamics involved in swinging and stopping loads and boom deflection from hoisting loads; and

- Know and understand the relevant requirements of the provisions of the standard relating to signals.

Under 29 CFR 1926.1428, employers must determine that a signal person is qualified through the assessment of a qualified evaluator, who must meet one of the following definitions in §1926.1401:

- Third party qualified evaluator ("an entity that, due to its independence and expertise, has demonstrated that it is competent in accurately assessing whether individuals meet the qualification requirements in this subpart for a signal person."). The signal person must have documentation from a third party qualified evaluator showing that he or she meets the qualification requirements.

- Employer's qualified evaluator (not a third party) ("a person employed by the signal person's employer who has demonstrated that he/she is competent in accurately assessing whether individuals meet the Qualification Requirements in this subpart for a signal person."). The employer's qualified evaluator assesses the individual, determines that the individual meets the qualification requirements, and provides documentation of that determination. This assessment may not be relied on by other employers.

(See 1/9/12 Interpretation Letter to William Irwin, Jr., and 6/28/11 Interpretation Letter to Walter Wise).

No, but employers must have documentation of the signal person's qualifications available at the worksite, either in paper form or electronically. For example, the documentation may be accessed from a laptop or tablet, via e-mail, or be transmitted from an offsite location by facsimile. While a physical card may serve as proof of a signal person's qualifications, it is not the only means allowed by the cranes standard. The documentation must specify each type of signaling (e.g., hand signals, radio signals, etc.) for which the signal person is qualified under the requirements of the standard. The purpose of this documentation is to ensure the onsite availability of a means for crane operators and others to determine quickly whether a signal person is qualified to perform a particular signal for the hoisting job safely. (See 1/9/12 Interpretation Letter to William Irwin, Jr., and 6/28/11 Interpretation Letter to Walter Wise).

OSHA's cranes standard requires each employer of a signal person to use a qualified evaluator (a third party or an employee) to verify that the signal person possesses a minimum set of knowledge and skills (29 CFR 1926.1428(a)). In general, OSHA does not evaluate or endorse specific products or programs, and therefore makes no determination as to whether a certification program meets the definition of a "qualified evaluator (third party)." It should be noted, however, that in the preamble to the cranes standard, OSHA stated that "labor-management joint apprenticeship training programs that train and assess signal persons would typically meet the definition for a third-party qualified evaluator...." (See the preamble to the cranes standard in the Federal Register at 75 FR 48029). With regard to training, the employer is ultimately responsible for assuring that its employees are adequately trained regardless of whether the employees' qualification is assessed by the employer or a third party. (See 1/9/12 Interpretation Letter to William Irwin, Jr., and 6/28/11 Interpretation Letter to Walter Wise).

No. To qualify as a signal person, the operator would need to be evaluated by a qualified evaluator, satisfy the specified testing requirements for signal persons under 29 CFR 1926.1428, and documentation must identify the types of signaling (e.g., hand, radio, etc.) for which the operator has been evaluated. In some cases, the operator's certification process may also satisfy the signal person qualification requirements, depending on the qualifications of the certifying organization, the content of the certification exam, and the documentation provided by the certifying organization. In general, the qualifications of a signal person and an equipment operator are not considered one in the same.

Not necessarily. While being an accredited trainer may indicate that the trainer possesses the skills for effectively communicating subject matter to trainees, a qualified evaluator must also have demonstrated that he or she is competent in accurately assessing whether individuals have the qualifications required by the cranes standard. For further information regarding signal person qualifications, refer to related fact sheets.

Equipment Issues

Sections 1926.1425(c)(2) and 1926.1433(d)(4) do not apply to slings. However, if the use of slings without self-closing latches for a particular rigging job would be inconsistent with industry-recognized precautions designed to protect against the load becoming displaced, such as manufacturer's recommendations or a consensus standard for rigging, OSHA could cite such a hazard under the OSH Act's general duty clause.

No. The cranes standard does not require all equipment to be equipped with outriggers. However, if the equipment is manufactured with outriggers, they must be either fully extended or, if the manufacturer's procedures permit, deployed as specified in the load chart.

No. The outrigger sensor/monitor device required by the cranes standard must enable the operator to accurately confirm the position of the outriggers in order to comply with the manufacturer's procedures and load charts. However, this requirement does not prohibit advances in safety through design and engineering, such as when a manufacturer chooses to exceed OSHA's minimum safety requirements by equipping cranes with interlocks that prohibit operation if the outriggers are not extended properly. (See 3/13/12 Interpretation Letter to Curtis Imerman).

The cranes standard requires that the operations procedures (including load charts) must be available in the cab. Either electronic or hardcopies are allowed (29 CFR 1926.1417(c)). Criteria for what information must be on the load charts is specified in 29 CFR 1926.1433(d)(1).

However, if the operating procedures are provided electronically, and the electronics fail, the operator must stop operations until the load chart information is available in the cab. Such information could be made available via a hardcopy, or through other functioning electronic devices including, but not limited to, a laptop, phone screen, or tablet, as long as all of the information specified in 29 CFR 1926.1433(d)(1) is available. In short, as long as an electronic source of required information is functional, such as a functioning load moment indicator system (LMI), hardcopies of this information are not required.

Cranes Standard Basics and Background

The cranes standard can be accessed from www.osha.gov. The preamble to the final rule can also be found on OSHA's website under "Federal Register Notices" for August 9, 2010 or on the Federal Register website (www.gpoaccess.gov) under Vol. 75, page 47906.

The final rule is available in 29 CFR Part 1926, which can be ordered from the Government Printing Office at https://bookstore.gpo.gov.

For compliance assistance regarding application of the final rule contact: Directorate of Construction, Room N3468, OSHA, U.S. Department of Labor, 200 Constitution Avenue, NW, Washington, DC 20210; telephone (202) 693-2020 or fax (202) 693-1689.

A number of factors led OSHA to decide to undertake a rulemaking. One factor was the approximately 22 fatalities and 175 injuries that were occurring on average per year. To prevent more of these injuries and deaths, a number of hazards needed to be more adequately addressed such as: cranes and derricks contacting power lines; workers caught in or struck by the equipment; unsafe work practices; and equipment tipovers. In addition, there have been considerable technological advances in equipment since the publication of subpart N. Investigations of several high-profile crane incidents emphasized the need to update the cranes standard to address hazards related to the use of newer equipment, technologies, and techniques used during hoisting activities. These factors led OSHA's Advisory Committee on Construction Safety and Health, a group of construction experts, who advise the Agency on construction safety and health standards, to recommend that OSHA update its cranes standard.

The prior cranes standard, 29 CFR 1926.550, was published in 1971. It was amended twice, in 1988 to address the use of personnel platforms (29 CFR 1926.550(g)) and in 1993 to ensure that “[a]ll employees shall be kept clear of loads about to be lifted and of suspended loads” (29 CFR 1926.550(a)(19)).

The 23 C-DAC members on the Crane and Derrick Negotiated Rulemaking Committee (C-DAC) represented a wide variety of interests. These included crane and derrick manufacturers, suppliers, owners, leasing companies, construction companies that use cranes and derricks, general contractors, labor organizations representing construction employees who operate and work with cranes, electric utilities, the insurance industry and government.

The former standard for cranes and derricks used in construction work (29 CFR 1926.550) incorporated requirements of certain pre-1970 national consensus standards. The current cranes standard sets forth most of its requirements in the text of the standard and incorporates national consensus standards by reference in only a few locations. In addition, this standard includes a number of new provisions designed to improve safety. Several significant changes are:

- Employers, including crane users and controlling contractors, must ensure that ground conditions are adequate to safely support the equipment.

- New requirements applicable to assembly and disassembly that will protect workers from being struck or crushed by unanticipated movement of crane components, as well as require equipment to be properly assembled.

- New requirements for maintaining sufficient clearance distances from power lines hazards.

- New requirements for pre-erection inspection of tower cranes, use of synthetic slings during climbing of tower cranes and other assembly activities, and use of qualified riggers for those activities.

- Fall protection requirements are clarified in the standard.

- The current rule expands upon the requirements for equipment (such as floating cranes) that was subject to few requirements in the prior standard.

- As discussed above, the cranes standard also included a requirement that, effective November 10, 2014, most operators must be formally qualified or certified. OSHA has published a final rule that extends the deadline for crane operator certification by three years, to November 10, 2017, and that preserves the employer's duty for interim operator assessment for that extended period.