Woodworking eTool

Rough Mill Equipment » Straight Line/Gang Rip Saws

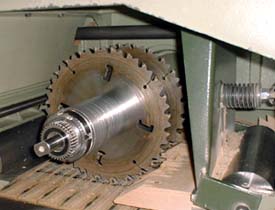

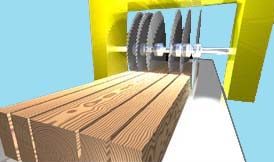

A straight line or gang rip saw is a circular blade machine, usually of the radial design, used for cutting stock across and above the stock. The blade is mounted directly to the motor, which is contained in the movable ram. The stroke may be manual or powered. The saw blade generally rotates at 3600 rotations per minute (RPM). Stock is fed in front of the machine on a feed table with rolls and guides ross the stock. After the cut is complete, the blade must return to its original position behind the stock and the stock is repositioned for the next cut.

Operator Involvement

This type of saw requires the operator to position the stock, hold it stationary, and grasp the sawing mechanism.

-

-

>> Straight Line/Gang Rip Saws

Potential Hazard

-

Point of operation - Contact with the blade may occur during operation, when the saw is idling, if the return device fails, or if the saw bounces forward from a retracted position.

Possible Solutions

Engineering Controls

-

Enclose upper half of saw and arbor end with a self-adjusting hood. The hood must drop on top of and remain in contact with the table or stock. When the saw returns to the back of the table, the hood must cover the lower portion of the blade [29 CFR 1910.213(g)(1)].

-

Ensure that the saw contains an automatic device (such as a counterweight) to return the saw to the back of the table after the cut has been made [29 CFR 1910.213(g)(2)].

-

Install a latch with a ratchet release on the handle, non-recoil spring, bumper, or other device to keep the saw from rebounding from its idle position.

-

Use limit chains or other means to keep the saw from moving beyond the front or back edge of the table [29 CFR 1910.213(g)(3)].

-

Enclose overhead drive with a fixed guard [29 CFR 1910.219].

Work Practices

-

Position the piece to be cut before starting the saw.

-

Stand at the side of the saw blade when the saw is running and use the hand nearest the handle to operate the saw. This keeps the operator's body out of the line of the saw.

-

Keep hands out of the line of the cut.

Potential Hazard

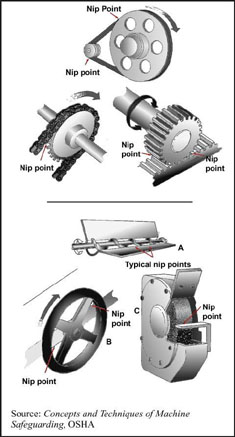

- In-running nip points - Clothing, hair, or hands may be caught by and pulled into the in-running rolls of the automatic feed.

Possible Solution

Work Practices

- Stand at the side of the saw blade when the saw is running and use the hand nearest the handle to operate the saw. This keeps the operator's body out of the line of the saw.

Potential Hazard

- Kickback - Stock caught by the blade may be thrown back at the operator.

Possible Solutions

Engineering Controls

-

Enclose overhead drive with a fixed guard [29 CFR 1910.219].

Work Practices

-

Position the piece to be cut before starting the saw.

-

Stand at the side of the saw blade when the saw is running and use the hand nearest the handle to operate the saw. This keeps the operator's body out of the line of the saw.

-

Make sure guards and counterweights are properly adjusted at all times. Take improperly adjusted saws out of service [29 CFR 1910.213(s)(1)].

Potential Hazard

- Flying particles - the cutting action of the blade may throw wood chips, splinters, and broken saw teeth.

Possible Solutions

Engineering Controls

-

Enclose the overhead drive with a fixed guard. [29 CFR 1910.219].

Work Practices

-

Stand at the side of the saw blade when the saw is running and use the hand nearest the handle to operate the saw. This keeps the operator's body out of the line of the saw.

-

Remove cracked and defective saw blades from service [29 CFR 1910.213(s)(7)].

-

Make sure guards and counterweights are properly adjusted at all times. Take improperly adjusted saws out of service [29 CFR 1910.213(s)(1)].