Woodworking eTool

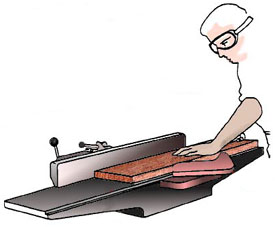

Woodworking » Kickbacks

Kickbacks occur when a saw seizes the stock and hurls it back at the operator. This can happen when the stock twists and binds against the side of the blades or is caught in the teeth. A blade that is not sharpened, or that is set at an incorrect height, can cause kickbacks. Poor-quality lumber (in other words, frozen lumber or lumber with many knots or foreign objects such as nails) can also result in kickbacks. Kickbacks occur more often when cutting parallel to the wood grain (ripping) than when cross-cutting.

- The major hazard with kickbacks is the stock being hurled back at the operator. Hazards due to kickbacks are most likely when there is a lack of safeguards, such as spreaders, anti-kickback fingers, and gauge or rip fences.

Engineering Controls

-

Use a spreader to prevent material from squeezing the saw or kicking back during ripping.

-

Use anti-kickback fingers on both sides of the blade to hold the stock down in the event that the saw kicks back the material.

Work Practice Controls

-

Use appropriate equipment for the job. Workers can be seriously injured if they do not use the correct equipment for a job. Use machines only for work within the rated capacity specified by the machine manufacturer. Use the correct tools on a given machine. For example, when using a circular saw, use the correct blade for the required cutting action. Similarly, you must only mount blades, cutter heads, or collars on machine arbors that have been accurately sized and shaped to fit these parts.

-

Frequently inspect equipment and guards. Ensure that: (1) the operator and machine are equipped with the safety accessories suitable for the hazards of the job, (2) the machine and safety equipment are in proper working condition, and (3) the machine operator is properly trained. Document the inspections and keep the records. Documentation should identify the machine, inspection date, problems noted, and corrective action taken. Noting problems helps to ensure that corrective action will be taken, that operators on all shifts will be made aware of any potential danger, and that any pattern of repeat problems on a particular machine can be detected and resolved as early as possible.

-

Do not use stock that has checks, splits, cracks, or knots.

-

Allow glued joints to dry before working on stock.

-

Hold tools firmly in both hands.

-

Use equipment only when guards are in place and in working order. A worker should not be allowed to operate a piece of woodworking equipment if the guard or any other safety device, return device, spreader, anti-kickback fingers apparatus, guard on in-running rolls, or gauge or rip fence is not functioning properly. When guards cannot be used (during rabbeting or dadoing, for instance), you must provide combs, featherboards, or suitable jigs for holding the stock.

-

Provide regular preventive maintenance. Regularly clean and maintain woodworking equipment and guards. Ensure that blades are in good condition. Knives and cutting heads must be kept sharp, properly adjusted, and secured. Sharpening blades prevents kickback. You must also remove any cracked or damaged blades from service. Keep circular saw blades round and balanced. You must remove dull, badly set, improperly filed or improperly tensioned saws from service, and immediately clean saws to which gum has adhered.

-

Avoid deep cuts; they increase the likelihood of kickbacks.

-

Use appropriate personal protective equipment.

-

Whenever possible, stand back or to the side once the boards have been put through to avoid injuries from kickback and flying splinters.

-

Do not feed boards of different thickness. Thinner boards will be kicked back.