Woodworking eTool

Rough Mill Equipment » Jointers

Jointers face or flatten wood and are used primarily to joint small pieces of material. The operator passes stock over a cylindrical, multiple-knife cutter head, while keeping the stock flush against a guide. The depth of the cut is achieved by adjusting the front table. There are two types of jointers: hand-fed jointers with a horizontal cutting head, and wood jointers with a vertical head.

Injuries can occur if the operator's hands and fingers come in contact with the knives. This can happen when the operator is jointing narrow lengths of stock, particularly when not using a jig or other holding device. Injuries can occur when the operator's fingers ride along the surface of the jointer while feeding the wood. Also, stock may be accidentally kicked away, exposing the operator's hands to the cutter head.

Potential Hazard

-

Point of operation - Contact with the knives may occur, especially if a holding device is not used.

Possible Solution

Engineering Controls

For hand-fed jointers, horizontal head:

-

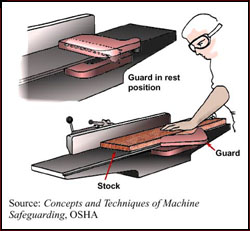

Enclose cutter head with an automatic (spring-loaded, self-enclosing) guard that exposes the cutter head only when the stock is being fed. The guard must automatically adjust to cover the unused portion of the head, and it must remain in contact with the material at all times [29 CFR 1910.213(j)(3)]. The figure at the right shows the appropriate use of a self-adjusting guard.

-

Adjust the cylindrical cutter head so that the knife projects no more than 1/8 inch beyond the cylindrical body of the head [29 CFR 1910.213(j)(1)].

-

Adjust the cutter head so that the clearance between the path of the knife projection and the rear table is no more than 1/8 inch [29 CFR 1910.213(j)(2)].

-

Keep the clearance between the table and the head as small as possible [29 CFR 1910.213(j)(2)].

For vertical head jointers:

-

Completely enclose cutter head, except for slot to apply the material for jointing. This guard can be part of the local exhaust system.

Work Practices

-

Use hold-down push blocks when jointing wood narrower than 3 inches.

-

As a general rule, never joint pieces of material that are less than four times the width of the bed opening.

Potential Hazard

-

Kickbacks - Stock may be thrown back at the operator after being caught by the knives. This also may expose the operator's hands to the knives.

Possible Solution

Work Practices

-

Avoid deep cuts. They increase the likelihood of kickbacks and require a larger table opening.

Potential Hazard

-

Flying chips - The cutting action of the knives may throw wood chips and splinters.

Possible Solution

Work Practices

-

Check knives regularly for proper setting and adjustment, but be sure to shut off the power first.