Emergency Preparedness and Response

Emergencies can create a variety of hazards for workers in the impacted area. Preparing before an emergency incident plays a vital role in ensuring that employers and workers have the necessary equipment, know where to go, and know how to keep themselves safe when an emergency occurs. These Emergency Preparedness and Response pages provide information on how to prepare and train for emergencies and the hazards to be aware of when an emergency occurs. The pages provide information for employers and workers across industries, and for workers who will be responding to the emergency.

General Preparedness and Response

- Getting Started:

- OSHA Emergency Response Rulemaking

- Hazardous Waste Operations and Emergency Response (HAZWOPER)

- Psychological Resiliency

- ARC Ready Rating Program

- ARC Emergency App

Natural Disasters and Weather

- Earthquakes

- Floods

- Heat

- Hurricanes

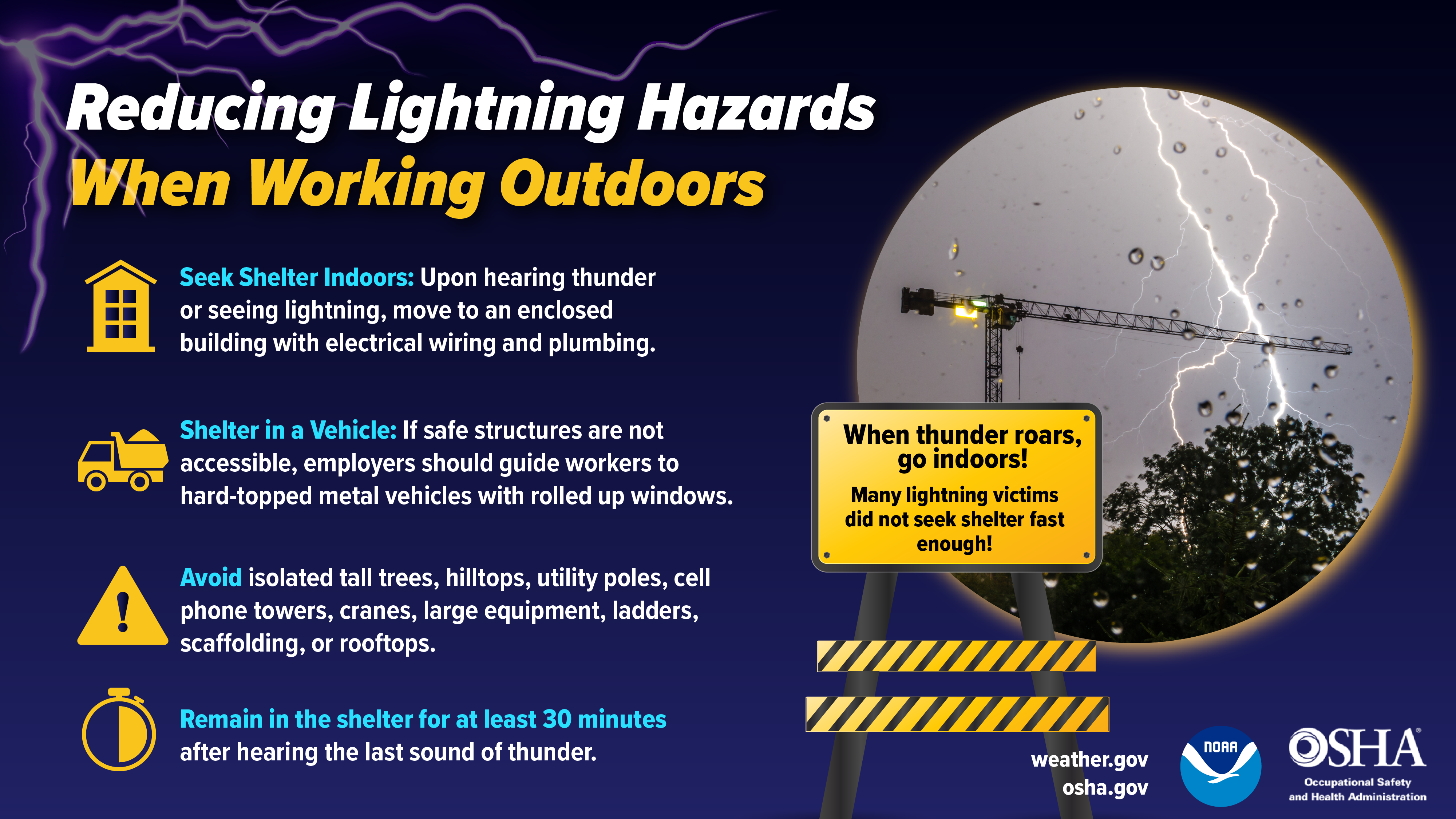

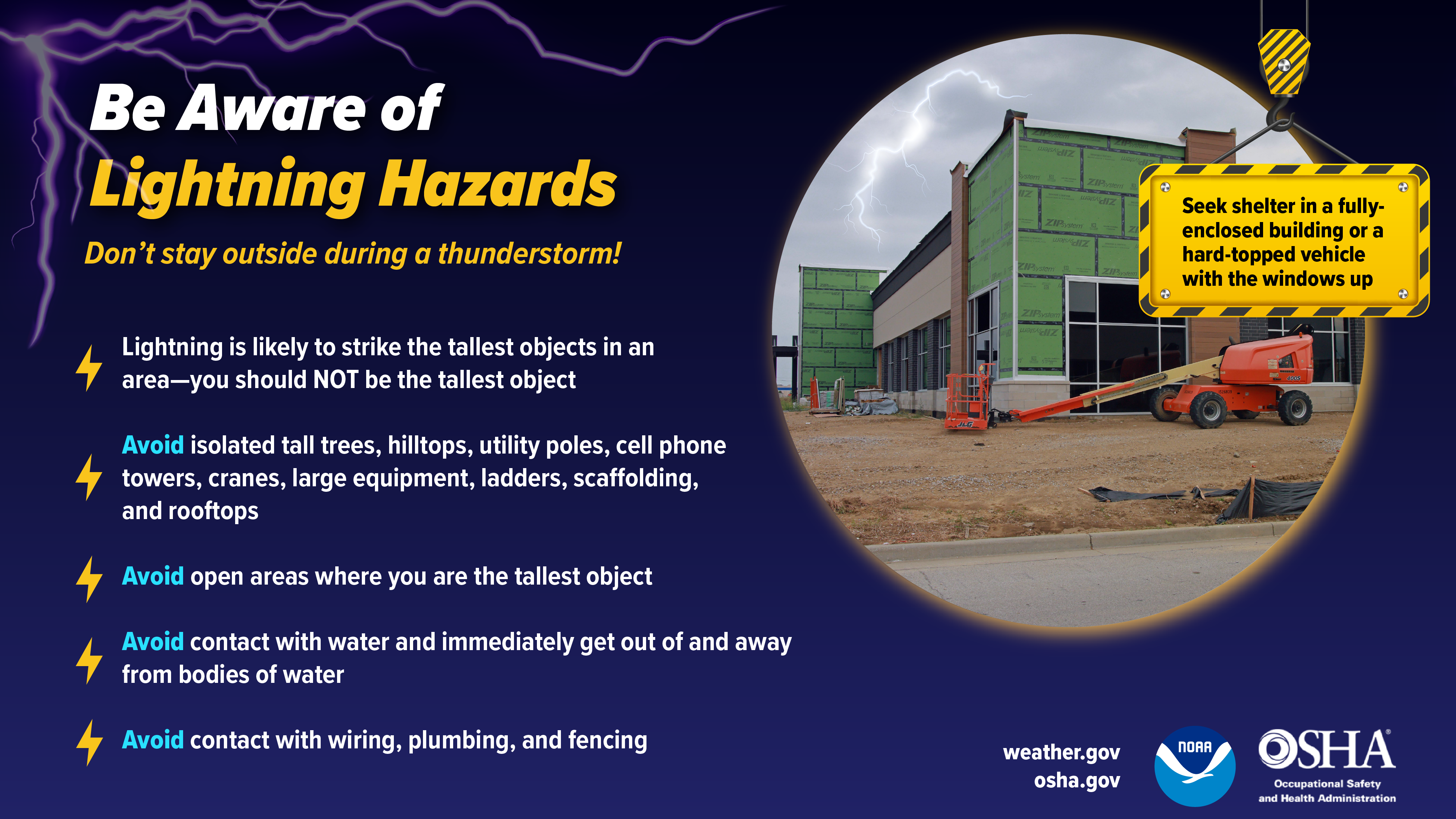

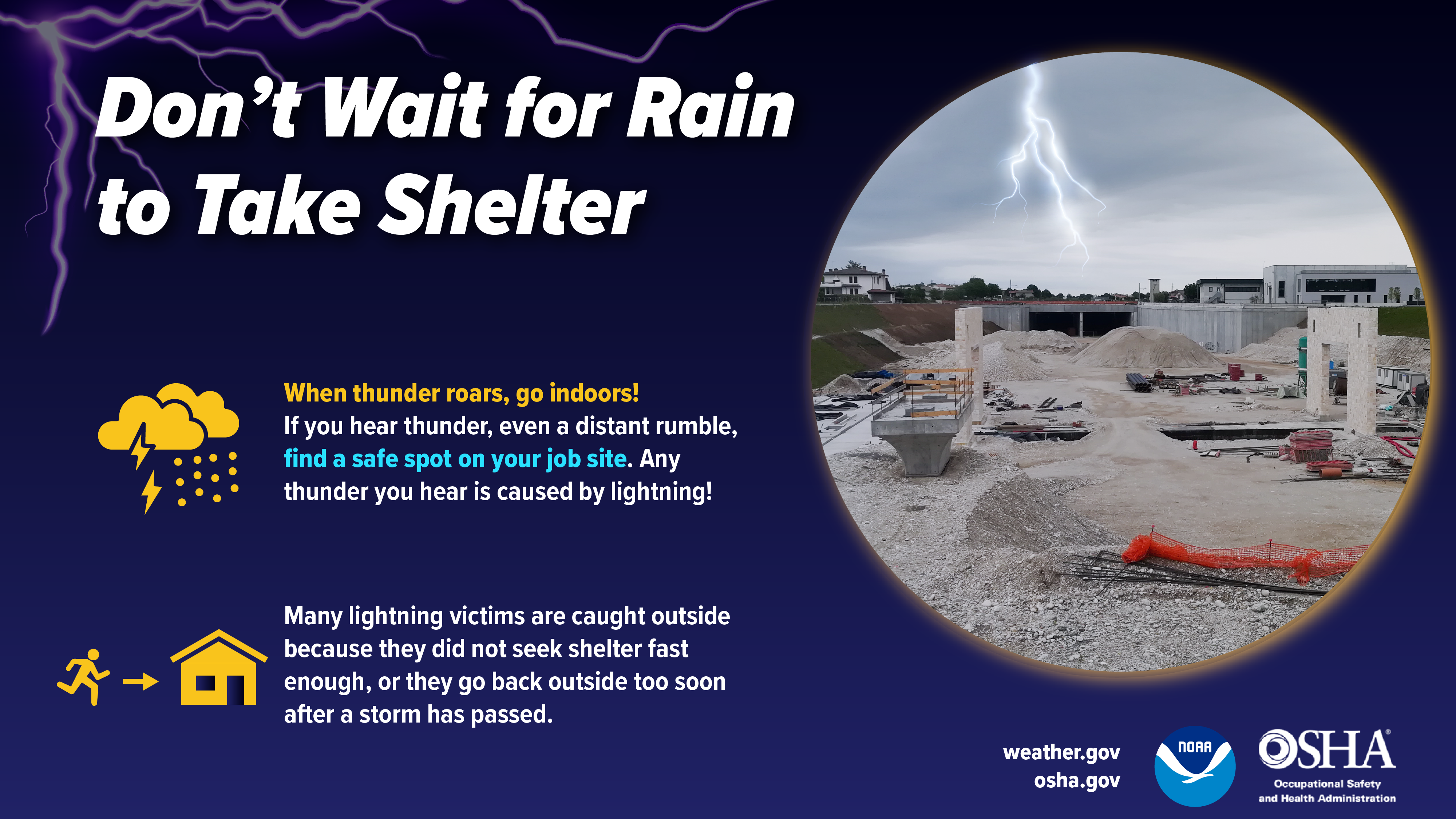

- Lightning Safety

- Severe Weather

- Tornadoes

- Wildland Fire Smoke

- Wildfires

- Winter Weather

Oil; Chemical, Biological, Radiological, Nuclear, and Explosive (CBRNE) Incidents

- Biological Incidents

- Bomb/Explosion

- Chemical Incidents

- Fourth Generation Agent (FGA) Nerve Agent Resources for First Responders and First Receivers

- GF (Cyclosarin)

- Lewisite (L) Quick Reference Guide

- Mustard-Lewisite Mixture (HL) Quick Reference Guide

- Plague (Yersinia Pestis)

- Sarin (GB) Quick Reference Guide

- Soman (GD) Quick Reference Guide

- Sulfur Mustard (HD) Quick Reference Guide

- Tabun (GA) Quick Reference Guide

- VX Quick Reference Guide

- Oil Spills

- Preventing Emergency Responder Fatigue

- Radiation Emergencies

Disease Agents and Toxins