OSHA Field Safety and Health Management System (SHMS) Manual

CHAPTER 27. EXPOSURE MONITORING

-

Purpose.

This chapter establishes OSHA's Exposure Self-Monitoring Program. The policies and procedures in this program are intended to set broad expectations for “self-monitoring” to prevent employee illness, injury, or death from exposure to chemical, biological, radiological, and physical health hazards (including assessments and sampling). It is expected that OSHA offices implement these specific procedures that align with this Program.

This program is also intended to identify whether personnel exposures indicate a need for short- or long-term medical intervention to prevent or respond to hazardous exposures.

-

Scope.

The program applies to all OSHA personnel within a regional, area, district, and satellite OSHA office and other OSHA organizational units (e.g. the OSHA Technical Center (OTC) and Office of Training and Education (OTE)) covered by the OSHA SHMS Manual.

-

References.

29 Code of Federal Regulations Section 1910.1020, Access to Employee Exposure and Medical Records

Recommended Practices for Safety and Health Programs

OSHA Instruction TED 01-00-015, OSHA Technical Manual

OSHA Occupational Chemical Database

OSHA Field SHMS Manual ADM 04-00-003:

Chapter 2 - Safety and Health Management System (SHMS) Chapter 12 - Hazard Communication

Chapter 16 - Hearing Conservation

Chapter 18 – Respiratory Protection

Chapter 21 - Radiation

Chapter 25 - Medical ManagementNIOSH Pocket Guide to Chemical Hazards

OSHA Letter of Interpretation: Enforcement Policy for Respiratory Hazards Not Covered by OSHA Permissible Exposure Limits.

American Conference of Governmental Industrial Hygienists (ACGIH): Threshold Limit Values (TLVs®) and Biological Exposure Indices (BEIs®).

-

Cancellations.

NA

-

Action Offices.

OSHA Regional and Area Offices, Directorate of Technical Support and Emergency Management, Directorate of Administrative Programs – Office of Training and Education Responsible Office.

-

Federal Program Change.

NA

-

Significant Changes.

The OSHA SHMS Manual, Chapter 27, "Exposure Self-Monitoring" is a revised chapter program that provides updated information and clearly defined scope to include guidance and accountability of all OSHA personnel. This revision also details the responsibilities of OSHA personnel, and the procedures related to the OSHA SHMS Manual instruction's maintenance and implementation. The key changes incorporated into this chapter are:

- Definitions of common terminology

- Updated details of the roles and responsibilities of OSHA National and Field personnel

- Guidance for hazard assessment, staff notifications and incident reporting

- Updated exposure data collection procedures for self-monitoring of noise

- Reorganization of the appendices provided and updates to the Chemical Self-Monitoring Decision Flowchart

-

Definitions

Contaminant: any material which by reason of its action upon, within, or to a person is likely to cause physical harm. See 29 CFR 1926.107(a).

Covered Employees/Personnel: All OSHA personnel assigned to duties in which there is reasonable anticipation of encountering physical, chemical, radiological and/or biological hazards. These OSHA personnel are also covered in the mandatory OSHA Medical Examination Program (OMEP). (See SHMS Chapter 25: Medical Management for more information.)

Exposure or exposed: The state in which an employee is subjected to physical, chemical, radiological and/or biological hazards in the course of employment through any route of entry (inhalation, ingestion, skin contact or absorption, etc.), and includes past exposure and potential (e.g., accidental or possible) exposure.

Non-covered employees: Any person other than a Covered employee as defined in this chapter that could be monitored or sampled (e.g. consultants, other federal employees, etc.).

Occupational Exposure Limit (OEL): Exposure limits developed by OSHA and external organizations including but not limited to Recommended Exposure Limits (RELs) issued by the National Institute for Occupational Safety and Health (NIOSH) and Threshold Limit Values (TLVs) published by the American Conference of Government Industrial Hygienists (ACGIH).

OSHA Technical Support System (OTSS): A web-based system used to document measurements for exposure assessment samples. The OTSS is also used to order expendable supplies for OSHA's field work, including sampling media, and to request technical support equipment (TSE) such as that used for exposure monitoring. Such TSE items are available from the OSHA Technical Center (OTC) through either a temporary loan, or permanent transfer from the OTC to an area office.

Permissible Exposure Limit (PEL): Regulatory limits for air contaminants in a workplace set by OSHA.

Professional judgment: The usage of relevant training, knowledge, and experience to make informed decisions about the courses of action that are appropriate in the circumstances. Professional judgment can be theoretical or practical.

Self-Monitoring: Any type of self-hazard assessment that can be conducted to determine one's exposure. Self-monitoring may include full shift monitoring, screen sampling, passive sampling, and exposure assessment using direct reading instruments.

Self-Sampling: The physical collection of samples using equipment, tubes, badges, etc.

Skin designation/notation: A warning that a chemical has the potential for significant contribution to the overall exposure via the skin (including mucous membranes and eyes) causing systemic effects even when airborne exposures are below the exposure limit.

-

Responsibilities

-

National Office

-

Office of Occupational Medicine and Nursing (OOMN):

If OSHA personnel have the potential to be exposed to a chemical, biological, radiological, or physical hazard, they should conduct self-monitoring during the course of their work. If an exposure exceeding an OEL or OSHA PEL is noted by the employee, the Regional Administrator/Directorate Director (RAs/Directors) will notify OOMN via the confidential email system in place, within a reasonable time frame following the date of exposure. The details of the exposure are to be relayed using SHMS Chapter 2 - Safety and Health Management System, Appendix C: Hazard Reporting and Incident Investigation Worksheet. This completed worksheet along with any OTC laboratory data as well as the laboratory request form should be provided to OOMN. In the event the Safety and Health Committee (SHC) has notified OOMN of a concerning exposure exceeding an OEL, OOMN will determine if the exposure requires additional medical follow-up or biological monitoring. This may include referral for a periodic exam and/or an expert medical opinion. OOMN will notify the RAs/Director as appropriate.

OOMN will provide consultation for OSHA personnel in accordance with SHMS Chapter 25 - Medical Management. OOMN does not provide direct medical care for the employee but can make recommendations to the agency.

-

OSHA Technical Center (OTC):

Provide consultation and resources for OSHA personnel as requested. Sampling Equipment and media can be obtained through OTC's Field Support Programs.

-

-

RAs/Directors are responsible for each employee's work-related safety and health in the Region/Directorate and will:

- Implement this exposure self-monitoring program in their region/directorate.

- Support self-monitoring when setting performance expectations and developing policies and procedures.

- Provide managers with the authority and resources necessary to carry out their responsibilities in this program.

- Request assistance from the OTC's Health Response Team (HRT) for investigations and inspections with the potential for exposure to chemical, biological, radiological, or physical hazards when the Region/Directorate does not have the resources to safely assess or conduct work activities.

- Ensure OOMN is notified that an employee has been medically evaluated due to work-related exposures, including exposures above a published OEL. OOMN will request medical documentation from the employee, as necessary, and provide direction for medical follow-up under the OSHA Medical examination program or if medical surveillance is indicated as best practice.

Note: The employee may elect to give their supervisor medical information, but the supervisor should not ask for specific medical information. Supervisors can ask for the information required for recordkeeping and per other DOL/OSHA policy for leave.

-

SHCs are responsible for tracking and evaluating field personnel exposures and will:

- Evaluate incidents when exposures exceed any published OEL, or an employee experiences adverse health effects related to an exposure to a contaminant to determine if appropriate protections were used and what follow-up may be needed. This evaluation is not for disciplinary purposes.

- Notify the RA when there are work-related exposures above a published OEL of OSHA personnel.

- Review at least annually Region/OTC/OTE exposure data for trends.

- Conduct an annual review of this program and make appropriate recommendations.

-

Area Directors (AD) and equivalent for OTC and OTE are responsible for implementing this Program in each Field office/organizational unit and will:

- Ensure that monitoring data is collected and recorded by OSHA personnel and reviewed by supervisors.

- Ensure sampling media and direct reading equipment is readily available and calibrated.

- Train employees on hazardous chemicals, as directed by the Regional Hazard Communication Program; see SHMS Chapter 12: Hazard Communication for more information.

- Train employees on Respiratory Protection, as directed by the Regional Respiratory Protection Program; see SHMS Chapter 18: Respiratory Protection. For more information See Section IX. Training.

- Ensure training is provided for all sampling equipment used.

- When necessary, complete a Hazard Reporting and Incident Investigation Worksheet (see SHMS Chapter 2: SHMS for more information) with the assistance of the affected employee;

- Ensure the Regional SHC or equivalent for OTC/OTE is notified of all exposures above any published OEL. See OSHA's Permissible Exposure Limits – Annotated Tables and other expanded health standards, as appropriate, for more information. The AD should ensure that the Regional SHC is provided an exposure packet that includes at least the following:

- A completed Hazard Reporting and Incident Investigation Worksheet; and

- Documentation of the exposure with sampling results. (E.g. OIS exposure assessments, exposure records, sample sheets, self-sampling developed on OIS).

-

OSHA's covered personnel will participate in OSHA's Exposure Self- Monitoring program and will:

- Exercise professional judgment to determine where potential exposures exist for themselves. OSHA personnel may decide to self-monitor at any time. See Section V.A.1 for recommended monitoring.

- Contact their supervisor for guidance if they are unsure about performing monitoring prior to spending time in an area where potential for exposure may exist.

- Review the establishment's Safety Data Sheets (SDSs) and/or chemical inventory in accordance with other provisions in the Regional/OTC/OTE SHMS (e.g., Hazard Communication Program) during the opening conference to evaluate the potential exposures that may be encountered during the inspection.

- Perform necessary self-sampling (including but not limited to, air, wipe, or bulk sampling) of potential contaminants when occupational health exposures may occur.

- Complete sampling documentation in the OSHA Information System (OIS), see Appendix A: Creating a CSHO Sampling Record – OIS Instructions.

- If necessary, assist the AD/office manager in completing a Hazard Reporting and Incident Investigation Worksheet and include the following details:

- Have OSHA Staff (CSHOs, AAD, etc.) been exposed above the OEL to this hazard in the past? If so, when?

- Did the OSHA Staff experience any health effects? If so, what were the effects?

- Attach the relevant OIS Health Sampling sheet(s) and Safety Data Sheets.

- Are the employer's employees being over exposed to this hazard?

- If additional information is needed, it will be requested as necessary.

- Notify the Area Director via their supervisor when self-sampling exposure levels exceed any published OEL or when OSHA personnel experience signs and symptoms of exposure.

- If it is determined that self-monitoring is not needed, justification is to be documented (e.g. capture this information in the internal communications section of a case file).

-

-

Exposure Data Collection Procedures

Covered Employees will monitor their exposures including but not limited to: air contaminants, noise, radiation, biological and other physical hazards. Self-sampling may include full shift monitoring, screen sampling, passive sampling, and exposure assessment using direct reading instruments. Covered Employees will use professional judgment to determine the appropriate sampling method, refer to Occupational Chemical Database Sampling and Analytical Methods for sampling guidance. When conducting joint safety and health inspections, follow generally accepted industrial hygiene practices.

Sample results are compared to applicable OELs, such as: OSHA permissible exposure limit (PEL), the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Value (TLV), National Institute for Occupational Safety and Health (NIOSH) Recommended Exposure Limit (REL), or the chemical manufacturer's OEL.

Based on sample results, in coordination with OSHA's Field SHMS National Labor-Management Steering Committee, OOMN may request additional data to determine if additional medical surveillance is required in the OMEP program.

Note: Sampling can be entered into OIS for non-covered employees. To enter these samples, select the related inspection as “No” in the self-sampling module. The user will then be prompted to enter the activity being performed while sampling is conducted for exposed non-covered employees.

-

Self-Monitoring for Chemicals

Covered Employees will perform self-monitoring for chemical, biological, radiological and physical hazard exposure where appropriate, based on good industrial hygiene practices (i.e. anticipate, recognize, evaluate, and control the hazard(s)) and/or based the following conditions:

-

Self-monitoring is required when:

-

A company's employees are potentially exposed to contaminants at hazardous levels. Covered Employees at the location (e.g., in a joint safety and health inspection effort) will self-monitor, even if not taking samples from the company's employees;

-

Covered Employees have potential for exposure (long duration, short duration, or instantaneous); or

-

At least one of the following is true: (One of the below)

-

The chemical is covered by an expanded health standard and/or an emphasis program (national, regional, or local).

-

The chemical is a carcinogen or a sensitizer.

-

The chemical has an unusually low OEL, for example <1 ppm or the mg/m3 equivalent (mg/m3 equivalent applies only to gases and vapors; see the OSHA Technical Manual, Section II, Chapter 1, Personal Sampling for Air Contaminants, Appendix M, to convert between ppm and mg/m3).

-

The chemical in c.i. through c.iii. has an OEL that has a skin designation.

-

-

-

Self-sampling is not required under the previous conditions if one or more of the following conditions are met and with supervisor approval:

-

Covered employees are not in the immediate area where work is being conducted.

-

The chemical has a low volatility or is not part of a process where it may be dispersed as an aerosol or where degradation may produce gas and vapor exposures.

-

-

Covered Employees may self-sample any time they decide it is warranted.

-

-

Self-Monitoring for Noise

In most situations, self-sampling for noise is highly recommended. Self-monitoring for noise (i.e. a sound level meter or a noise dosimeter) is required when noise levels may exceed the Action Level or 85 dba; it is used to determine when hearing protection is not adequate and the situation requires a change in location or proactive hearing protection. See OTM Section III: Chapter 5 III. Measurements A. Equipment.

Noise exposure data will provide the covered employee with real time information to determine the need for additional hearing protection or to increase the distance from the source. Covered Employees should self-monitor for noise exposure any time they determine, with the use of professional judgment, that it is necessary for determination of the need for double hearing protection, see SHMS Chapter 16: Hearing Conservation – Appendix D Estimating HPD Attenuation using NRR or PAR for more information.

Covered Employees will enter all noise exposure monitoring data, including screening, into OIS. See Appendix A.

-

The OSHA Hearing Conservation Program requires the use of fit tested personal protective equipment (PPE) and audiometric examinations. Audiometric examinations are conducted during routine medical evaluations. See OSHA SHMS Manual Chapter 16, Hearing Conservation, for additional information.

-

Self-Monitoring for Other Physical or Biological Hazards

Covered Employees will perform monitoring for physical agents (e.g., radiation, thermal stress). Covered Employees will enter such monitoring data results into OIS. See Appendix A.

When Covered OSHA personnel encounter a situation where radiation, biological hazards, or thermal stress is present, they will contact their supervisor to determine the need and appropriate method for self-monitoring. See OTM Section III: Ch 4. Heat Stress, OTM Section III: Ch 6. Laser Hazards, and OSHA SHMS Chapter 21.

OSHA personnel should assess the potential for heat-related illnesses, injuries, and deaths where heat-related hazards may exist in indoor work areas or at outdoor work areas on heat priority days when the heat index is expected to be 80°F or higher. For inspections/investigations related to Heat, OSHA personnel shall refer to the OSHA Technical Manual (OTM) | Occupational Safety and Health Administration and other internal documents for more information.

Covered Employees may arrange for self-sampling any time their professional judgement determines it is necessary.

-

-

Exposure Records

An "employee exposure record" is defined in 29 CFR 1910.1020(c)(5). For purposes of this program, the information contained in the OIS self-sampling records constitutes an employee exposure record. The employee exposure record shall be recorded as outlined in Appendix A: Creating a CSHO Sampling Record – OIS Instructions. See below for details related to access and availability of these employee exposure records.

-

Access

Covered Employees will have access to their own employee exposure records without the need for submitting a formal, written request for the records.

-

Availability

-

Under the Freedom of Information Act (FOIA), 5 U.S.C. §552, exposure monitoring records, regardless of where they are stored or maintained, might be released in response to requests from various parties. In most cases, the Covered Employee's name and Compliance Safety and Health Officer (CSHO) ID number will be redacted, based on Exemption 6 (information about specific individuals in “personnel and medical files and similar files” when the disclosure of such information would constitute a clearly unwarranted invasion of personal privacy) and/or Exemption 7(c) (records or information compiled for law enforcement purposes to the extent that such information could reasonably be expected to constitute an unwarranted invasion of personal privacy) of the Freedom of Information Act.

-

The Privacy Act of 1974, 5 U.S.C. §552a, is not generally applicable to establishment case files. The Privacy Act permits an individual to seek access to only his/her own records and only if that record is maintained by the Agency within a system of records and retrieved by the individual requester's name or personal identifiers.

-

If an inspection is contested, exposure monitoring information might be released during the discovery process. Exposure monitoring information would be made accessible to the parties involved in the litigation (including the establishment inspected, the union representing the employees if they have elected party status) representing attorneys and the judge. Under discovery, it is unlikely that the Covered Employee's name or CSHO ID number could be redacted.

-

-

-

Exposure Follow-Up

-

During a site visit, if covered employees recognize that they may be overexposed, they will take appropriate steps to remove themselves from risk and minimize further exposure. The primary action following such an exposure is to implement controls to reduce or prevent additional exposure.

-

Covered Employees will notify their manager, who will notify the applicable OSHA Field SHMS SHC whenever there is a known or suspected exposure exceeding the OEL, see Chapter 2: Safety and Health Management System, Section IV, Incident Reporting/Investigation Procedures.

-

The applicable SHC will review any known or suspected exposure incident and determine if the case should be referred to the Director of OOMN. The OOMN Director can determine if this information should be included within the employee's medical record. OOMN will determine the need for further medical evaluation, if necessary. Medical surveillance may be provided to employees exposed at levels greater than established OELs or experiencing signs and symptoms of exposure as determined by OOMN as part of the OMEP program.

Note: Employees experiencing acute health effects from exposure to a hazard should seek or be sent for urgent or emergency care immediately, prior to OOMN notification. OOMN does not provide medical care for employees.

-

The applicable SHC may make recommendations regarding current and future use of appropriate personal protective equipment, administrative controls, and work practices to the appropriate OSHA management.

-

-

Training

All Covered OSHA personnel must receive training upon hiring and at least biennially on:

-

The requirements contained in this program.

-

Exposure data collection methods, data collection equipment.

-

Trends from the applicable SHC annual review.

-

The specific substances referenced in Appendix B: Chemical Exposure Hazards, to ensure familiarity and provide references on where to obtain additional information.

-

How to enter self-monitoring data into OIS.

Additional training is necessary if conditions such as data collection methods change. Retraining will occur when the supervisor determines that a Covered Employee may not possess adequate understanding or skill to self-monitor and/or prevent exposure to hazardous chemicals.

Non-covered Employees can participate in this training for awareness purposes.

-

-

Data Tracking and Retention

Covered Employee exposure records are established and entered into OIS. Appendix A: Creating a CSHO Sampling Record – OIS Instructions, is detailed and includes screen shots for correctly completing the form and accessing records in OIS. A paper file need not be created because the electronic records are maintained in OIS longer than the 30 years required under CFR 1910.1020. See 29 CFR 1910.1020(d)(i)(ii). Covered Employees may create paper copies for their own records.

APPENDIX A

CREATING A CSHO SAMPLING RECORD—OIS INSTRUCTIONS

Creating a CSHO Self-Sampling Activity

Most CSHO sampling records are associated with an inspection. Enter the associated inspection first, and then enter the self-sampling activity.

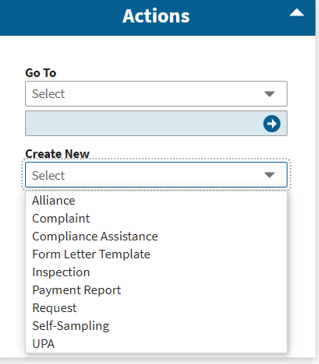

To create a self-sampling activity, click on Self-Sampling in the Create New drop down in OIS.

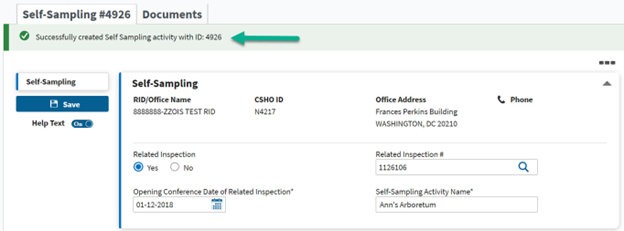

If the CSHO is assigned to more than one RID, they will be prompted to select the RID to which the self-sampling will be attached (the default is the CSHO's primary RID). Otherwise, they will be brought directly into the Self-Sampling activity record. All office information including the RID, Office Name, and office Address are pre-populated into the self-sampling activity based on the RID selection.

The CSHO will then enter the enforcement inspection number to which the self-sampling activity will be attached. The system will then pre-fill the opening conference date of the related inspection as well as the associated establishment into the self-sampling activity. Once these field entries are completed, click "Save". This will create the Self-Sampling activity number in OIS.

*NOTE: If the self- sampling is NOT related to an inspection (e.g., sampling at the Area, Regional, or National Office), the CSHO can simply enter the date the sampling was conducted as the "Opening Conference Date" and the location of the sampling as the "Self Sampling Activity Name".

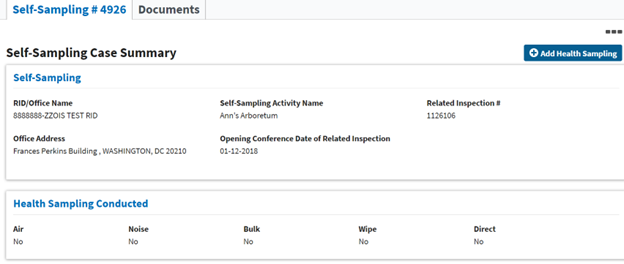

To proceed with exposure record and sample sheet entry, click on the ellipsis in the upper right corner of the screen, and then click "Go to Case Summary".

This will return the CSHO to the Case Summary Screen, at which time they will click on + Health Sampling to proceed with Exposure Record and Sampling Sheet Data entry.

The exposure record will automatically be prefilled with the Job Title of CSHO, CSHO ID, CSHO's name, and RID information. The CSHO may choose to enter some basic information about the process as well. Once the CSHO clicks "Save", the Exposure Record will have been created, and the CSHO may proceed with entry of sample sheets as they normally would for any other sampling activity.

APPENDIX B

CHEMICAL EXPOSURE HAZARDS

Chemicals covered by an expanded OSHA health standard

4-Nitrobiphenyl

alpha-Naphthylamine

Methyl chloromethyl ether

3,3'-Dichlorobenzidine and its salts

bis- Chloromethyl ether

beta-Naphthylamine

Benzidine

4-Aminodiphenyl

Ethyleneimine

beta-Propiolactone

2-Acetylaminofluorene

4- Dimethylaminoazobenzene

N-Nitrosodimethylamine

1,2 –dibromo-3-chloropropane

1,3-Butadiene

Acrylonitrile

Asbestos

Benzene

Beryllium

Cadmium

Chromium (VI)

Coke Oven emissions

Cotton dust

Ethylene oxide

Formaldehyde

Inorganic arsenic

Lead

Methylene chloride

Methylenedianiline

Silica

Vinyl chloride

Chemicals with poor warning properties, high odor thresholds, very low OELs, or special interest chemicals (this list is not all inclusive)

Chemicals covered by NEPs, LEPs, REPs or any other specific targeting program:

Acetylene

Cannabis

Carbon monoxide

Carbon tetrachloride

Chloroform

Dichlorobenzene

Ethylene oxide

Formamide

Heptane

Hexavalent Chromium

Hydrogen sulfide

Lead

N-bromopropane

Pharmaceutical dusts

Silica

Styrene

Please check the latest current active emphasis programs OSHA Emphasis Programs.