Electric Power Generation, Transmission, and Distribution eTool

Electric Power Generation, Transmission, and Distribution » Insulating Protective Equipment (IPE)

Insulating Protective Equipment (IPE) includes items such as:

- Insulating (rubber) line hose, blankets, and hoods.

- Insulating barriers made of fiberglass or phenolic resin.

- Live-line tools such as hotsticks, switchsticks, and shotgun sticks.

- Plastic or fiberglass hardcover items that can be installed with live-line tools.

IPE and Minimum Approach Distances

Like PPE (for example, insulating gloves and sleeves), IPE is used to provide workers protection from contacting energized conductors, but unlike PPE it is not worn on the body. Properly covering (or "guarding") exposed live parts with IPE between the live parts and workers allows 269-qualified employees to enter the Minimum Approach Distance without having to wear insulating PPE. [See 1910.269(l)(2)]. Also see ASTM Standards D 178, D 1048, D 1049, and D 1050 for specifications on Insulating Matting, Insulating Blankets, Insulating Covers, and Insulating Line Hose.) However, IPE often has limited protective functionality. For example, some IPE, such as line hose, is designed to protect qualified employees from brush contact only. Thus, company practice frequently requires the use of insulating gloves and sleeves in addition to IPE when workers are working within the MAD.

IPE Ratings and Testing

Rubber and hardcover IPE items must be rated for the voltage of the parts being covered (phase to ground or phase to phase) and are designated from Class 0 (up to 1KV) through Class 4 (up to 36KV). Many of these items are, however, only designed for protection during incidental or brush contact. Rubber line hose and hoods need to be electrically tested when there is any indication that the insulating value is suspect. Rubber blankets must be tested at intervals of not more than 12 months. [See 1910.137(b).]

Inspection and Storage

Each item of IPE must be inspected for possible defects before each day's use. Items must be stored properly by avoiding folding, excessive heat, sunlight, humidity, ozone, and any chemical or substance that could damage the item. (See ASTM F479, Standard Specification for In-Service Care of Insulating Blankets, ASTM F478, Standard Specification for In-Service Care of Insulating Line Hose and Covers, and ASTM F1236, Standard Guide for Visual Inspection of Electrical Protective Rubber Products.)

Barriers and Insulating Covers

See:

1910.269(p)(4)(iii)(A), (B), and (C) on Insulating Protective Equipment (IPE) (under Mechanical Equipment)

Barriers or insulating covers can be used to prevent worker contact with energized parts. These barriers and insulating covers, which are designed for the primary purpose of protecting against the contact and electrocution hazard, can also sometimes reduce the exposure to or effects of an arc blast, or arc flash. When used to insulate live parts from possible contact with tools or metallic objects, barriers can prevent an electric arc from occurring in the first place. In the event of equipment failure, thoroughly secured heavy blankets can also limit the effects of the arc blast or flash.

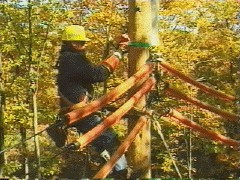

Live Line Tools

Live line tools (for example, hotsticks, switchsticks, shotgun sticks) must be wiped clean and inspected for defects before each day's use. The "269" standard (1910.269(j)(2)) requires that if any potential defect is found, the live line tool must be removed from service for formal examination and testing. When live line tools are used as primary protection, they must be removed from service at least every 2 years for examination, cleaning, and any required testing. Repaired tools must be retested. [See 1910.269(j)(2)(iii) and IEEE Std. 978, Guide for In-Service Maintenance and Electrical Testing of Live-Line Tools.]

Minimum Approach Distances (MAD)

Personal Protective Equipment (PPE)

Equipotential Zone

Line-Clearance Tree Trimming Operations

Overhead Line Work

Use of Aerial Lifts

Hazard Assessments and Job Briefings