Oil Spills

Preparedness

Preparing before a potential oil spill emergency response plays a vital role in ensuring that employers and workers have the necessary equipment, know where to go, and know how to stay safe and healthy in the event of an actual emergency. This tab provides information on how to prepare and train for oil spill response, recovery, and cleanup. The tab addresses critical information for employers and workers across all industries, as well as specifically for emergency response workers.

The sections below discuss oil spill preparedness and planning required by federal agencies:

- Occupational Safety and Health Administration (OSHA), U.S. Department of Labor;

- U.S. Coast Guard (USCG), U.S. Department of Homeland Security (DHS);

- U.S. Environmental Protection Agency (EPA);

- Pipeline and Hazardous Materials Safety Administration (PHMSA), U.S. Department of Transportation (DOT); and

- Bureau of Safety and Environmental Enforcement (BSEE), U.S. Department of the Interior.1

An important part of preparedness for oil spill response, recovery, and cleanup workers and employers is awareness of common hazards. Table 2 summarizes information about common hazards. Exposure to any of these hazards depends on what workers are actually doing, where they are working, and the type and state of the spilled oil.

This page is organized by four major sections, with subsections as outlined below:

This section is organized by:

- Oil Spill Response Plans

- Hazardous Waste Operations and Emergency Response (HAZWOPER)

- Health and Safety Plans (HASPs)

Oil Spill Response Plans

Table 3 summarizes information about oil spill response planning under USCG, EPA, PHMSA, and BSEE regulations. It also identifies the regulatory requirements for these oil spill response plans. Response actions conducted under the NCP must comply with the provisions of OSHA's HAZWOPER standard (40 CFR 300.150). See the Background page for more information on the NCP and ACPs.

Plan holder generally refers to an owner or operator of a facility or vessel required to have an oil spill response plan under federal regulations to prepare for oil spills or substantial threats of oil spills. Some emergency response workers for oil spill emergencies will be working for a plan holder.

More frequently, emergency response workers for oil spill response emergencies will be working under an Oil Spill Removal Organization (OSRO). In general, an OSRO provides oil spill response resources to remove oil from the environment or mitigate associated impacts. OSROs include, but are not limited to, providers for source control, mechanical recovery, dispersants, bioremediation, in‐situ burning, or other spill countermeasures, as well as any contractor, cooperative, or in‐house provider of oil spill removal resources established in a geographic area to provide oil spill removal resources required by regulation. See Table 3 for OSRO regulatory references.

Federal agency regulations use different terms for an oil spill response plan (see Table 3). An oil spill response plan typically identifies the number of workers required to mobilize and operate the oil spill response equipment at each site. All workers must have the qualifications and training required for their position within the response organization. An oil spill response plan typically includes worker safety and health provisions for emergency response, recovery, and cleanup.

For the USCG, for example, the plan must identify and ensure availability of response resources, which includes the workers, equipment, supplies, and other capabilities necessary to perform the identified response activities. Response resources can be owned or contracted, and dedicated or non-dedicated. For USCG plans:

- Full-time workers are a dedicated resource, which means workers dedicated primarily to oil spill response, cleanup, and spill containment. Such workers are not used for any other activity that would adversely affect their ability to provide oil spill response services. Owned and dedicated resources (equipment and workers) can mobilize faster than resources that are contracted.

- Part-time workers are a non-dedicated resource. Such workers are not limited exclusively to oil spill response-related activities. Because non-dedicated resources (equipment and workers) may not be available to respond immediately, they may have extended notification and mobilization times.

Hazardous Waste Operations and Emergency Response (HAZWOPER)

Employers whose workers will be involved in emergency response operations for releases of, or substantial threats of releases of, hazardous substances regardless of the location of the hazard must comply with OSHA's Hazardous Waste Operations and Emergency Response (HAZWOPER) standard, 29 CFR 1910.120 and 29 CFR 1926.65. This may include emergency response and post-emergency response cleanup following an oil spill incident. Instruction CPL 02-02-073 describes OSHA enforcement procedures under the relevant provisions of the HAZWOPER standard.

Under the HAZWOPER standard, employers must develop and implement comprehensive safety and health programs that include the following components:

- Organizational structure

- Comprehensive work plan

- Site-specific health and safety plan

- Emergency response plan

- Safety and health training program

- Medical surveillance program

- Standard operating procedures

- Site characterization and analysis

- Exposure monitoring

- Engineering controls

- Safe work practices

- PPE, if needed

- Handling/labeling of drums and containers

- Decontamination procedures, and

- Other regulated required programs.

OSHA's HAZWOPER Safety and Health Topics page further explains requirements of the OSHA HAZWOPER standard, including required worker training.

The U.S. Environmental Protection Agency (EPA) has promulgated a standard applying OSHA's HAZWOPER standard to state and local government workers in states where there is no OSHA-approved State Plan. See 40 CFR Part 311.

HAZWOPER Coverage for Volunteers

Volunteers frequently participate in oil spill response operations, but Federal OSHA standards do not cover uncompensated workers. In states approved to manage their own occupational health and safety program (called OSHA State Plans), volunteers are often covered under state plan HAZWOPER requirements. In states administered by Federal OSHA, volunteers are covered by the U.S. Environmental Protection Agency (EPA) HAZWOPER standard (40 CFR 311). EPA’s HAZWOPER standard has identical requirements, but the coverage is different from Federal OSHA standard coverage. The EPA HAZWOPER standard covers local and state government workers, both compensated and volunteers.

The National Response Team (NRT) developed a guidance document for federal On Scene Coordinators (OSCs) and Area Committees (ACs) using or considering using volunteers during an oil spill incident. It was developed in response to incident lessons learned and contains information, examples, and tools to help with everything from coordination and outreach, to organization and oversight, safety and health, and also includes tips on avoiding some of the potential issues associated with utilizing a volunteer workforce.

Health and Safety Plans (HASPs)

For an oil spill emergency, employers must develop and implement a site-specific Health and Safety Plan (HASP). For larger oil spills, it is recommended that HASPs are coordinated and consistent among various sites (as appropriate).

HAZWOPER requires employers to have a detailed HASP to protect workers involved in cleanup operations (29 CFR 1910.120(b)(4)(ii)). The HASP identifies site hazards and appropriate controls to protect worker health and safety during oil spill cleanup operations. The HASP serves as a guide for employers and workers to follow during their response and cleanup operations to prevent the spread of contamination, injuries, and fatalities.

Employers should keep the HASP on-site and make it always available and easily accessible for workers, contractors, or subcontractors who will be involved with cleanup operations, as well as to OSHA personnel, and to personnel of any other regulatory agency with oversight, such as EPA.

PPE for Emergency Response and Recovery Workers

Employers of emergency response and recovery workers are responsible for ensuring that their workers have, and properly use, personal protective equipment (PPE) when necessary. PPE can include respiratory protection, protective clothing, and protective barriers used to protect workers from exposure to oil, oil by-products, dispersants, detergents, degreasers and other safety and health hazards. The selection of PPE is based on anticipated hazards and PPE selection may need to be modified as a result of monitoring and assessing actual working conditions. Some of the most common worker safety and health hazards during oil spills include heat stress, cold stress, slips, trips, and falls, skin and eye irritation, back injuries, and cuts and sprains. Table 2 summarizes information about common hazards. In planning for worker PPE needs, employers should conduct a site characterization for each job task and consider the full range of hazards a worker may experience (e.g., respirator cartridges suitable for both chemical and particulate exposures even if workers may only need protection from particulates most of the time) to determine the appropriate type and level of protection.

Different types and levels of PPE may be used depending on the specific hazard(s) present. PPE also may be needed to protect workers from other hazards, such as electric shock hazards or hazards associated with exposures to hazardous substances that may be encountered during emergency response and recovery operations.

The following are some important steps employers with emergency response and recovery workers, who may participate in oil spill response and cleanup operations, need to take with respect to PPE:

- Conduct a hazard assessment to determine what safety and health hazards workers may encounter;

- Follow the hierarchy of controls—including elimination/substitution and engineering, work practice, and administrative controls—before relying on PPE to protect workers;

- Determine what PPE workers need;

- Provide the proper PPE to workers;

- Train workers in the proper use of PPE, including how to put it on and take it off correctly, and how to clean, maintain and dispose of it after or between uses;

- Ensure that PPE is used properly and whenever necessary;

- Provide medical exams and/or fit testing, as required by OSHA standards, prior to using certain types of PPE (e.g., respirators); and

- Regularly review and update the PPE program as hazards change.

It is crucial that employers assess PPE needs for their workers in advance of an emergency. During and immediately after an emergency, there may be limited supplies of PPE available for purchase, so it is important to have the necessary PPE on hand in advance. In an emergency situation, employers may have little or no time to train or fit workers (e.g., perform fit testing for respirators), so it can be critical to have those tasks completed before an emergency occurs.

OSHA's Getting Started – PPE for Emergencies page provides information on PPE selection and use during emergency response and recovery operations.

OSHA's Respiratory Protection eTool provides instruction on proper respirator selection, use, and handling that employers with emergency response and recovery workers may find helpful.

In addition, OSHA's Respiratory Protection Safety and Health Topic Page provides links to a variety of guidance documents, web pages, and online tools related to respiratory protection.

Implementing an oil spill response effectively and safely requires all workers involved to develop competencies for their appropriate response capabilities. All workers with an identified role in a response organization should receive appropriate training. Managers need training to understand oil spill response management processes and to make effective decisions. Field managers and emergency response workers need training on deploying and using equipment, including its safe operating requirements, and on identifying hazards and implementing protections from hazards during job tasks.

This section is organized by:

- OSHA HAZWOPER Training Requirements for Emergency Response and Recovery Workers

- HAZWOPER in Other Federal Agency Training Regulations

- Specialized Training

OSHA HAZWOPER Training Requirements for Emergency Response and Recovery Workers

In accordance with OSHA's Hazardous Waste Operations and Emergency Response (HAZWOPER) standard, 29 CFR 1910.120 and 29 CFR 1926.65, all responders who enter a hazardous area, including an area where an oil spill is present, must receive certain training. Per 40 CFR 300.150, response actions conducted under the NCP must comply with the provisions of the HAZWOPER standard. Federal OSHA does not cover state and local government workers. Emergency responders employed by state or local governments are covered either by OSHA-approved State Plans (which must have standards that are at least as effective as the federal OSHA standards) or by the EPA's HAZWOPER standard, 40 CFR Part 311. (The EPA standard adopts OSHA's HAZWOPER standard by reference.)

The minimum amount of training required under HAZWOPER depends on the worker's role and responsibilities during the response, recovery, and cleanup, including whether the worker will be performing emergency response and/or post-emergency response cleanup operations. Before work begins, all workers must be trained on and demonstrate competence in the tasks they will conduct, the hazards associated with the tasks, and the precautions and protections needed to safely complete the tasks (e.g., use of engineering controls, safe work practices, PPE).

Because workers need to be trained before they respond, employers should train workers to the highest level of responsibility they might need to assume. This training must include the specific requirements for PPE for the different job tasks and hands-on training about PPE. Training must be provided in a manner and language that workers understand.

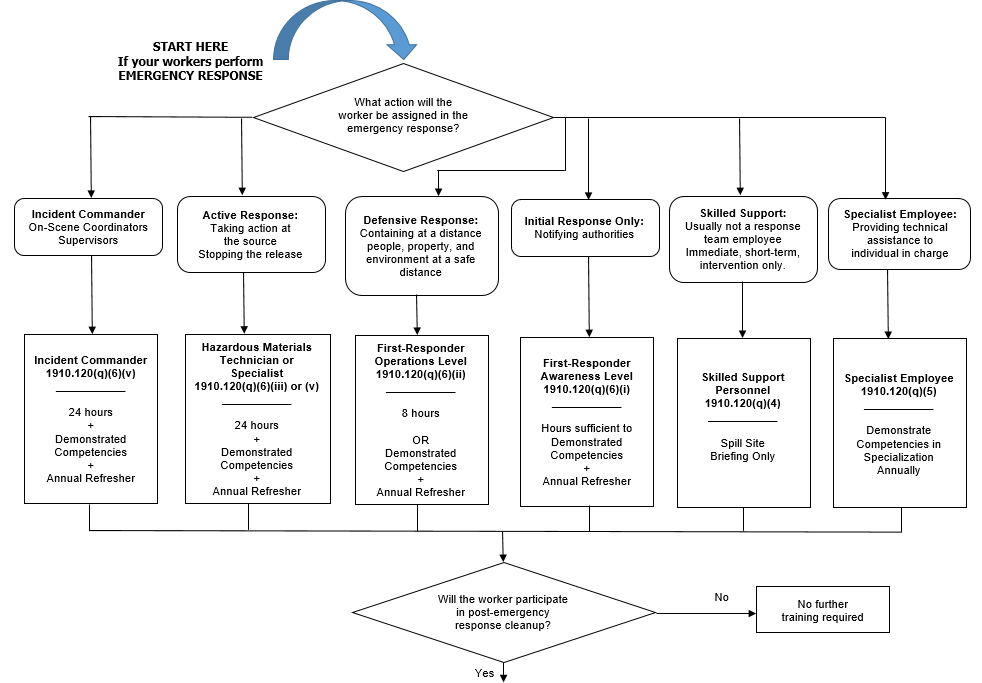

A decision flow chart shown below depicts training requirements for workers to perform emergency response operations.

For full training requirements, see 1910.120

Employers must never expect or allow workers to perform an emergency response or cleanup operation without proper training and certification. After the training is completed, employers must provide adequate supervision to ensure that safety protocols are followed.

OSHA publication 3114 Hazardous Waste Operations and Emergency Response provides guidance on HAZWOPER training requirements for various categories of workers. OSHA's HAZWOPER Safety and Health Topics page also provides information on HAZWOPER training requirements.

Further guidance on HAZWOPER training requirements for workers at marine oil spills is provided in OSHA publication 3172 Training Marine Oil Spill Response Workers under OSHA's Hazardous Waste Operations and Emergency Response Standard. HAZWOPER training requirements that apply to marine oil spill emergency response are located in 29 CFR 1910.120(q)(6). Requirements and training guidance for post-emergency response are in 29 CFR 1910.120(q)(11) which refers to 29 CFR 1910.120(b)-(o).

Post-Emergency Response Cleanup Operations

Per 29 CFR 1910.120(a)(3) of HAZWOPER, post-emergency response is performed after the immediate threat of a release has been stabilized or eliminated and cleanup of the site has begun. Shoreline cleanup is normally considered to be post-emergency response unless the oil is below the high tide mark or storm surge boundary (active or forecasted) and can reasonably be expected to be re-released into the environment. Depending on the size of the oil spill, the emergency and post-emergency response phases may be managed differently. However, particularly for large oil spills or a SONS, the emergency response and post-emergency response cleanup activities may occur at the same time. In these cases, the boundaries between the emergency response area and the post-emergency response area should be well defined and explained to responders and cleanup workers. Under HAZWOPER, workers who participate only in post-emergency response require different levels of training than emergency response workers.

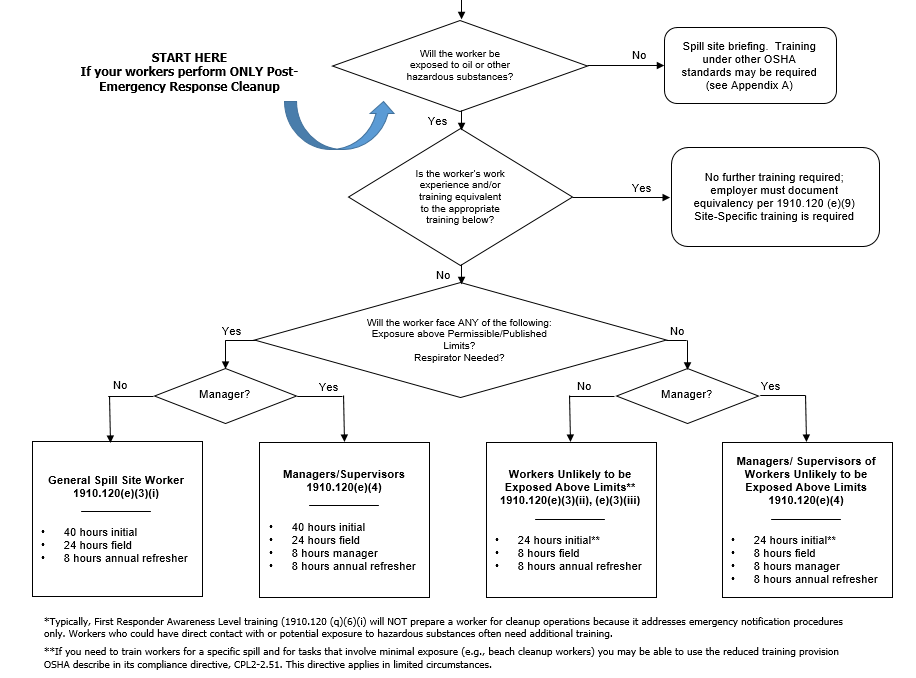

A decision flow chart shown below depicts training requirements for workers to perform post-emergency response cleanup operations.

For full training requirements, see 1910.120

Additional guidance on HAZWOPER training requirements for workers involved in post-emergency response operations is provided in OSHA’s Compliance Directive, CPL 02-02-051, Inspection Guidelines for Post-Emergency Response Operations Under 29 CFR 1910.120.

Based on experience with the HAZWOPER standard during oil spills off the coasts of Texas, Alaska, and California, hazards to workers may vary widely in severity of potential injury or illness. For job duties and responsibilities with a low magnitude of risk, fewer than 24 hours of training may be appropriate for these post-emergency response cleanup workers. For oil spill cleanup operations where 1) the site has been fully characterized, 2) respirators are not required, and 3) minimal exposure is likely, a minimum of four hours of training would be appropriate in most situations.2 Moreover, oil spills are unique in that many people who assist in the cleanup operations may not engage in this activity on a recurring basis. In addition, for maximum protection of the environment, oil spills dictate completion of cleanup as soon as possible.

Site-specific Worker Safety and Health Training

The site-specific Health and Safety Plan (HASP) must include a site training program that is designed to ensure that workers receive the training they need to work safely. Site safety and health training requirements are based on the job hazard analyses contained in the HASP and all relevant OSHA standards. A safety manager or officer typically oversees implementation of this training program and is responsible for ensuring that workers are adequately and currently trained for all tasks they are asked to perform. Workers who have not been trained to a level required by their job function and responsibility are not permitted to participate in or supervise field activities. Employers must provide training and required PPE to workers.

The NIEHS/OSHA oil spill cleanup training tool, Safety and Health Awareness for Oil Spill Cleanup Workers, provides a health and safety resource for awareness-level training for workers who will participate in an oil spill response, recovery, and cleanup. This tool is available in English (OSHA 3388 - 2010 v7); PDF), Spanish (OSHA 3391 - 2010 v5; PDF), and Vietnamese (OSHA 3394 - 2010 v4.1; PDF). Training must be provided in a manner and language that workers understand.

HAZWOPER in Other Federal Agency Training Regulations

Table 4 summarizes information about oil spill response training requirements in USCG, EPA, PHMSA, and BSEE regulations, and how OSHA’s HAZWOPER standard (29 CFR 1910.120) is included in those regulations. See Table 3 for more information on oil spill response planning under USCG, EPA, PHMSA, and BSEE regulations.

Specialized Training

Specialized training may be required for certain response operations. These additional training requirements under federal regulations may address worker safety and health.

USCG regulations require that all dispersant application workers be trained in and capable of applying dispersants according to the recommended procedures in ASTM F1737: "Standard Guide for Use of Oil Spill Dispersant Application Equipment During Spill Response: Boom and Nozzle Systems" (33 CFR 154.1045(i)(2)(iv) and 33 CFR 155.1050(k)(2)(iv)). USCG regulations also require that all dispersant application workers be trained in and capable of applying dispersants within the performance criteria in ASTM F1413: "Standard Guide for Oil Spill Dispersant Application Equipment: Boom and Nozzle Systems" (33 CFR 154.1045(i)(2)(iii) and 33 CFR 155.1050(k)(2)(iii)).

Under BSEE’s regulations, response workers at facilities conducting exploratory drilling from a Mobile Offshore Drilling Unit in the Arctic region may require additional training (30 CFR 254.90(a)). This training includes worker safety and health issues from cold stress and cold-related conditions that are associated with oil spill response activities in adverse Arctic weather conditions (33 CFR 254.70(b)) and, if relevant, the ability to sustain an effective offshore-based response capable of operating in adverse Arctic weather conditions (33 CFR 254.80(b)).

Equipment Deployment Exercises

Operational deployment of oil spill response equipment in the relevant operating environment can help:

- Ensure that field managers and emergency response workers are trained and competent to mobilize to an oil spill site and implement response plans safely, and

- Verify the equipment’s ability to function properly and the workers’ ability to use it safely.

Exercises are an opportunity to validate response strategies contained in response and contingency plans. Best practices for employers include exercises that can incorporate tests and field practice for worker safety and health procedures and equipment (e.g., PPE). Worker safety and health are paramount during an exercise or an actual response to an oil spill emergency.

This section is organized by:

Worker Safety and Health during Exercises

Field exercises provide an opportunity for additional hands-on experience for workers tasked with responding to an oil spill emergency, beyond the supervised field experience completed by workers required to complete the 40-hour HAZWOPER training. Exercises may include simulated or actual field experience for workers regarding the potential exposure to hazards, how to recognize the hazards, and how to control their exposure. Some exercises, such as drills, can also provide the opportunity to become familiar with oil spill response equipment, PPE, and safe work practices in a less stressful setting than an actual oil spill response emergency. Workers involved in actual field exercises will have the opportunity to practice performing site-specific responses safely that they may later be required to perform during an emergency.

Exercises can be used to evaluate:

- The organizational command and control structure (e.g., use of Unified Command) for worker safety and health activities;

- Accountability for worker safety and health regulatory requirements;

- Understanding of worker safety and health protections defined in the response plan and/or a detailed Health and Safety Plan (HASP) for the site or oil spill emergency;

- Effectiveness of site-specific worker safety and health training (if applicable);

- Procedures for job hazard analysis and operational-level hazards assessment;

- Comprehensive hazard prevention and control methods; and

- Safety incident reporting (e.g., safety incidents where workers are exposed to hazards, near-misses, unsafe conditions).

Types of Exercises

Exercises can be used to validate plans, policies, agreements, and procedures; clarify roles and responsibilities; and identify resource gaps. They are characterized by actual reaction to an exercise scenario, such as mobilizing workers and resources. Examples include:

-

Drills: Designed to validate a specific function or capability and are commonly used to provide training, validate procedures, or practice and maintain current skills. Incorporate worker health and safety to provide training for workers (from managers through on-site response workers) and opportunities to practice and maintain safety skills.

-

Spill of National Significance (SONS) Exercise

A SONS is defined in the NCP as an oil spill that due to its severity, size, location, actual or potential impact on the public health and welfare or the environment, or the necessary response effort, is so complex that it requires extraordinary coordination of federal, state, local, and responsible party resources to contain and clean up the discharge (40 CFR 300.5).

A SONS exercise tests the ability to implement higher level national coordination mechanisms and oil spill response policies.

Functional Exercise: Typically focused on exercising plans, policies, procedures, and staff members involved in management, direction, command, and control functions. Events are projected through an exercise scenario with event updates that drive activity typically at the management level. Conducted in a realistic, real‐time environment; however, movement of workers and equipment is usually simulated.

-

Full‐Scale Exercise: Typically the most complex and resource‐intensive type of exercise. Involve multiple agencies, organizations, and jurisdictions, and validate many facets of preparedness. Often include many participants operating under cooperative systems such as the ICS or UC. Events are projected through an exercise scenario with event updates that drive activity at the operational level. Usually conducted in a real‐time, stressful environment that is intended to mirror a real oil spill emergency—workers and resources may be mobilized and deployed to the scene, where actions are performed as if a real oil spill emergency had occurred. Simulates reality by presenting complex and realistic problems that require critical thinking, rapid problem solving, and effective responses by trained workers.

Discussion‐based Exercises

Discussion-based exercises include seminars, workshops, and tabletop exercises. These types of exercises can be used to familiarize participants with, or develop new, plans, policies, agreements, and procedures. Discussion‐based exercises focus on strategic, policy‐oriented issues. Facilitators and/or presenters usually lead the discussion, keeping participants on track towards meeting exercise objectives.

A tabletop exercise is intended to generate discussion of various issues regarding a hypothetical, simulated emergency, with participants collaboratively examining areas of concern and solving problems. Through involvement of participants, a table-top exercise can support assessment of recommended revisions to current policies, procedures, and plans.

Table 4 includes selected information about requirements for oil spill response exercises or drills in USCG, EPA, PHMSA, and BSEE regulations.

1 The primary statutory authority is Section 311 of the Clean Water Act, as amended by the Oil Pollution Act of 1990.

2 Per OSHA‘s Compliance Instruction CPL 02-02-051, criteria for when fewer than 24 hours of training may be appropriate for post-emergency cleanup workers include, but are not limited to, the following: the cleanup is performed in an area that has been monitored and fully characterized by a qualified person indicating that exposures are presently and can be expected to remain under permissible exposure limits and other published exposure limits, and health risks from skin absorption are minimal.