[Updated: September 15, 2017]

Heat Stress

Table of Contents:

- Introduction

- Heat-related Illness

- Heat-related Illness Prevention Program

- Heat Hazard Assessment

- Step 1: Determine WBGT

Step 1, Option A: Using a WBGT Meter

Step 1, Option B: Calculating WBGT Using Weather Data

The information regarding application of the ACGIH® Heat Stress and Strain TLV® is copyrighted by ACGIH® and is not publicly available. It may be accessed on the ACGIH® website subject to their permissions of use. OSHA personnel are directed to access OSHA’s intranet for more information.

- Step 1: Determine WBGT

- Example Problem

- References

I. Introduction

Heat-related fatality cases show that workplaces with temperatures above 70 degrees Fahrenheit may have a heat hazard present when work activities are at or above a moderate workload. Assessing worker exposure in conditions that may present a heat hazard is critical for knowing when to implement a heat-related illness prevention program. This OSHA Technical Manual (OTM) chapter provides technical information about indoor and outdoor heat hazards, illnesses, and prevention methods across all industries. The information will help to prepare OSHA compliance officers to conduct inspections and investigations. Specifically, this chapter provides technical information about using Wet Bulb Globe Temperature (WBGT) measurements to determine when heat exposure hazards are present in the workplace.

In February 2016, the National Institute for Occupational Safety and Health (NIOSH) published the Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments, a technical resource on heat stress, heat-related illness signs and symptoms, and heat programs. Although heat-related illness prevention programs are referenced in this OTM chapter, the chapter is not a guide for developing a program.

Figure 1. Heat-related illness risk factors

(NIOSH 2016)

II. Heat-related Illness

Although heat hazards are common in indoor and outdoor work environments, heat-related illness and fatalities are preventable. Many risk factors contribute to the risk for heat-related illness (see Figure 1.). A heat-related illness occurs when there is an increase in the worker's core body temperature above healthy levels. As core temperature rises, the body is less able to perform normal functions. As core temperature continues to increase, the body releases inflammatory agents associated with damage to the liver and muscles. This process may become self-sustaining and generate a run-away inflammatory response, the "systemic inflammatory response" syndrome that often leads to death.

The terms heat stress and heat strain represent the relationship and difference between external factors and the body's core temperature control mechanisms:

Heat Stress – The net heat load to which a worker is exposed. Physical exertion, environmental factors, and clothing worn all contribute to heat stress.

Heat Strain – The body's physiological response to heat stress (e.g., sweating).

The body's natural way to keep the core body temperature from rising to unhealthy levels is through an increase in heart rate and sweating. When these are not enough to keep the core body temperature from rising, the result is heat-related illness or death. Elevated core body temperatures may cause the following illnesses:

- Heat Stroke

- Heat Exhaustion

- Heat Cramps

- Heat Syncope

- Heat Rash

- Rhabdomyolysis

Heat Stroke is the most serious heat-related illness and should be treated as a medical emergency. Heat stroke occurs when the body becomes unable to adequately dissipate heat, losing the ability to regulate core body temperature. The core body temperature rises rapidly, the sweating mechanism may fail, and the body is unable to cool down. When heat stroke occurs, the body temperature can rise to 41oC (106°F) or higher within 10 to 15 minutes. Thinking clearly, perception, planning, and other mental processes become impaired, and the worker may be unable to recognize dangerous situations. Heat stroke can cause death or permanent disability if emergency medical treatment is not given. Symptoms include confusion, clumsiness, slurred speech, fainting/unconsciousness, hot dry skin, profuse sweating, seizures, and high body temperature.

Heat Exhaustion is often a precursor to heat stroke. It is often accompanied by elevated core body temperatures around 38°C–39°C (100.4°F–102.2°F). Symptoms may include headache, nausea, dizziness, fatigue, weakness, thirst, heavy sweating, irritability, and a decreased urine output.

Heat Cramps are caused by the body's depleted salt and water levels from excessive sweating resulting in muscle cramps or spasms. They usually occur in the muscles used during work. The symptoms include spastic contractions and pain in voluntary muscles mainly in the arms, legs, or torso.

Heat Syncope usually occurs after prolonged standing or sudden rising from a sitting or supine position. Heat syncope symptoms include light-headedness, dizziness, and fainting. Dehydration and inadequate acclimatization often contribute to heat syncope.

Heat Rash is skin irritation caused by excessive sweating. Excessive moisture and sweat obstructs sweat ducts and forms itchy and painful red pimple/blister clusters and skin lesions. It is exacerbated in hot and humid weather and common on the neck, chest, groin, armpits, elbow creases, and behind the knees.

Rhabdomyolysis is a medical condition, sometimes caused by heat stress and prolonged physical exertion, in which muscle fibers rapidly break down, die, and release electrolytes and proteins into the bloodstream. Left untreated, this can lead to kidney damage, seizures, irregular heart rhythms, and death. Symptoms include muscle cramps, muscle pain, dark urine, weakness, inability or decreased ability to perform physical exercise at the normally expected level or duration (i.e., exercise intolerance), and joint pain/stiffness.

Rhabdomyolysis is usually diagnosed when hospitalized using a test that measures elevated levels of a muscle protein called creatine kinase in the blood, abbreviated CK or CPK.

The NIOSH Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments Chapter 4 "Biologic Effects of Heat" provides more details about heat-related illnesses.

III. Heat-related Illness Prevention Program

An effective heat-related illness prevention program is incorporated in a broader safety and health program and aligns with OSHA's Recommended Practices for Safety and Health Programs core elements. Specifically, heat-related illness prevention is most effective when management commits to identifying and reducing exposure to heat stress hazards (i.e., heat hazards). The heat-related illness prevention program should establish how the employer will determine if workers are exposed to a heat hazard based on environmental conditions (e.g., weather or indoor temperature and humidity), clothing, and workload. The heat-related illness prevention program should also include policies/procedures for controlling heat hazards.

The American Conference of Governmental Industrial Hygienists (ACGIH®) has established an Action Limit (AL) for un-acclimatized workers and a Threshold Limit Value (TLV®) for acclimatized workers, see Heat Stress and Strain: TLV® Physical Agents 7th Edition Documentation (2017). These limits, which vary by WBGT and metabolic rate, are intended to maintain the core body temperature to within one degree Celsius of normal (37 degrees Celsius or 98.6 Fahrenheit for most people). ACGIH provides guidance for maintaining awareness about when workers may be exposed to heat stress above the AL or TLV so that preventive actions are taken to reduce the exposure. Heat-related illness prevention programs may include policies for using these guidelines to implement environmental controls, plan work schedules, and use personal protective equipment (PPE).

The most effective way to prevent heat-related illness and fatality is to reduce heat stress in the workplace (e.g., increase air movement, reduce temperature, reduce humidity, and protect workers from solar radiation or other radiant heat sources). The following are some engineering controls that may reduce heat stress:

- Use air conditioning

- Increase general ventilation

- Provide cooling fans

- Run local exhaust ventilation where heat is produced (e.g., laundry vents)

- Use reflective shields to block radiant heat

- Insulate hot surfaces (e.g., furnace walls)

- Stop leaking steam

- Provide shade for outdoor work sites

When engineering controls are not enough to keep worker exposure below the AL or TLV, administrative controls are another way to prevent a worker's core body temperature from rising. Some administrative controls that may reduce heat stress include:

- Acclimatize workers starting the first day working in the heat

- Re-acclimatize workers after extended absences

- Schedule work earlier or later in the day

- Use work/rest schedules

- Limit strenuous work (e.g., carrying heavy loads)

- Use relief workers when needed

When engineering and administrative controls are not enough, PPE is a way to provide supplemental protection. PPE that can reduce heat stress include:

- Fire proximity suits

- Water-cooled garments

- Air-cooled garments

- Cooling vests

- Wetted over-garments

- Sun hats

- Light colored clothing

- Sunscreen

An effective heat-related illness prevention program should include a worker acclimatization program, heat alert program, and medical monitoring program. It should also establish an effective training program that includes how to recognize heat-related illness symptoms and what to do when there is a heat-related illness emergency. OSHA recognizes that it may not always be feasible to implement all elements in all workplaces; however, implementing as many elements as possible will make the program as effective as possible.

Please see the NIOSH Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments and resources linked below for more detailed information.

The following list briefly describes several critical elements in a heat-related illness prevention program.

-

Acclimatization Program

To reduce the impact that heat stress will have on the core body temperature, employers should use a structured program to help workers adapt to working in the heat. An effective heat acclimatization program increases the time each day, over a 7 to 14 day period that an un-acclimatized worker is exposed to heat stress while the worker conducts normal work activities. Also, acclimatized workers who are not exposed to heat stress for a week or more may need some time to re-acclimatize ― typically two or three days. -

Medical Monitoring Program

More robust heat-related illness prevention programs establish a medical monitoring program to consider workers' individual needs for ensuring that their core body temperature does not reach unsafe levels and for early identification of signs that they are experiencing heat-related illness. This program should include preplacement and periodic medical evaluations, as well as a plan for monitoring worker health (e.g., core temperature, hydration, pulse, and/or blood pressure) on the job. The NIOSH Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments has more information about what to evaluate and monitor to prevent heat-related illness. -

Training Program

Specific heat-illness prevention training is important to ensure that supervisors and workers are prepared to work safely in hot environments. Training should include information about recognizing heat-related illness symptoms; proper hydration (e.g., drinking 1 cup [8 oz.] of water or other fluids every 15–20 minutes); heat-protective clothing and equipment care and use; other factors that affect heat tolerance (e.g., medications, alcohol, obesity, etc.); and how to acclimatize, report symptoms, work in pairs, and how to give appropriate first aid. Additionally, supervisors should also receive appropriate training on how to monitor weather reports and weather advisories, as well as how to use adjusted temperatures (e.g., WBGT and heat index) to make decisions about protective measures.An effective training program includes support from a safety and health professional with experience and/or training in heat stress and illness. First-line supervisor awareness and training is critical to ensuring that a heat-related illness prevention program is effectively implemented.

Heat Index use as an Adjusted Temperature

The heat index is a screening tool that uses temperature and relative humidity to calculate an adjusted temperature, representing how the conditions feel more accurately than just the ambient temperature. Since the WBGT uses four factors for calculating an adjusted temperature, it is even more accurate when determining if there is a heat hazard present. ACGIH, U.S. Armed Forces and athletic associations use WBGT for calculating an adjusted temperature in their guidance and policies.

For more information on the heat index, see the National Weather Service website.

-

Heat Alert Program

Effective heat alert programs (HAPs) are developed and implemented whenever a heat wave is likely to occur. The National Weather Service defines a heat wave as a period of abnormally and uncomfortably hot and unusually humid weather typically lasting two or more days. More specifically for workplaces, a heat wave is described by NIOSH as when the daily maximum temperature exceeds 35°C (95°F) or when the daily maximum temperature exceeds 32°C (90°F) and is 5°C (9°F) or more above the maximum reached on the preceding days.Details about actions to take during heat waves are provided in the NIOSH Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments Section 6.2.6 Heat Alert Program.

The following resources provide additional information for developing and implementing an effective heat-related illness prevention program:

IV. Heat Hazard Assessment

Environmental factors (e.g., humidity, wind, temperature, and radiant heat), clothing, and workload (i.e., metabolic rate) are considered when determining if there is a heat hazard present in an indoor or outdoor workplace. After the WBGT is measured, clothing adjustment factor added, and workload translated into metabolic rate; use the ACGIH TLV & Action Limit table to determine the risk for exposure to heat stress above the AL for un-acclimatized workers or the TLV for acclimatized workers.

-

Step 1: Determine WBGT

Figure 2. Quest WBGT meter with natural wet-bulb sensor

A WBGT meter (see Figure 2. and Figure 3.) is the most accurate tool for adjusting the temperature for heat stress factors including humidity, air movement (i.e., wind), radiant heat, and temperature. If a WBGT meter is not available or if the assessment is for hazards that may have been present in the past (e.g., heat hazard determination after a heat incident), the Argonne National Laboratory calculator uses an algorithm to adjust the temperature for heat stress factors using weather data available online.

An effective heat-related illness prevention program will describe the employer's policy for when and how often in the workday to measure WBGT. NIOSH recommends, in the 2016 Criteria for a Recommended Standard, taking environmental heat measurements at least hourly, during the hottest portion of each work shift, during the hottest months of the year, and when a heat wave occurs or is predicted.

WBGT measurements are most reliable when taken at, or as close as possible to, the work area. When a worker moves between two or more areas with different environmental conditions, or when the conditions vary substantially in the work area, assess the heat hazard using representative measurements for the different conditions.

Step 1, Option A: Using a WBGT Meter

Figure 3. Quest Waterless wet-bulb meter

WBGT meters have three sensors that input data into a calculation that adjusts the temperature to represent the impact humidity, wind, and radiant heat have on heat strain cooling effectiveness.

Dry-bulb thermometer: Thermometer that measures temperature without impact from other factors.

Natural (static) wet-bulb thermometer: Wetted thermometer used to measure sweat's effectiveness in cooling the body. It represents increased sweat evaporation potential when wind speed increases, and decreased sweat evaporation potential when there is more moisture in the air.

Black globe thermometer: Thermometer with hollow copper sphere painted on the outside with a matte black finish to measure the radiant energy from direct sunlight or other sources (e.g., machinery and hot structures near the workplace).

Some meters will also measure WBGT without the need to wet a bulb to determine wind and humidity adjustments (see Figure 3.). The waterless wet-bulb meter is a tested and validated alternative to the traditional natural wet-bulb sensor. The meter uses a mathematical model to determine the waterless wet-bulb calculation through a combination of dry-bulb temperature, globe temperature, relative humidity, and air flow sensors.

Although all the sensors measure temperature in Celsius and/or Fahrenheit, they represent different heat stress factors. The meter automatically calculates adjusted temperature using the sensor data inputs and programed equations. There are two different equations depending on whether the measurement is taken indoors (i.e., radiant heat unlikely or not solar) or outdoors (i.e., solar radiant heat likely). The data inputs are:

Tdb = the dry-bulb temperature

Tnwb = the natural wet-bulb temperature

Tg = the globe temperature

For outdoor environments, the meter uses all sensor data inputs in the following equation that weighs the wet bulb 70%, globe 20%, and dry bulb 10% of the weighted average:

WBGTout = 0.7Tnwb + 0.2Tg + 0.1Tdb

For indoor environments, the meter does not use the dry-bulb temperature since the globe and the dry-bulb should be equal without radiant heat. The globe temperature is used since it will also detect non-solar radiant heat sources if they are present. The equation weighs the wet-bulb 70% and the globe 30% of the weighted average:

WBGTin = 0.7Tnwb + 0.3Tg

These equations show the significant impact that changes in the wind speed and/or humidity can have on the WBGT. Also, for conditions with significant radiant heat source (i.e., sunny outdoors, foundries, glass manufacturers, boilers, etc.), the WBGTout will more accurately represent the environmental heat stress.

To calculate the WBGT for continuous all-day or several hour exposures, use the average WBGT over a 60-minute period. For intermittent exposures or exposures at different heat levels throughout a workday, average the temperature over a 60 to 120-minute period, depending on the exposure duration. The average WBGT (WBGTavg) is calculated using the following equation:

WBGTavg =

(WBGT1)(t1) + (WBGT2)(t2) + . . . + (WBGTn)(tn)

---------------------------------------

(t1) + (t2) + . . . + (tn)where tn = time in minutes

Using a meter to measure WBGT while physically at the worksite after a heat-related incident could provide an accurate localized perspective on the probability that there was a heat hazard during the incident. For example, WBGT measurement will capture radiant heat and wind reduction impacts from worksite structures or heat sources that historic weather from a remote location may not represent.

Consider the following when measuring WBGT post incident to determine the potential heat hazards at the time of an incident:

- Measure WBGT at the same time of day and in the same locations where the affected worker was working, resting, and treated, if possible. Consider recreating the worksite setup if structures or protection measures like tents were moved since the incident.

- Take into account weather condition differences on the day WBGT is measured versus the day the incident happened. For example, if conditions are cooler, windier, cloudier, and the WBGT measured indicates a heat hazard is present, it is likely there was a heat hazard present the day of the incident.

-

Consider comparing post-incident WBGT measurements to WBGT measurements taken the day of the incident, if available, to qualify data available at the time of the incident.

Step 1, Option B: Calculating WBGT Using Weather Data

Measuring WBGT at the site, or using historic WBGT logs/records, are the most accurate methods to make work/rest regimen decisions, or to assess the hazard after a heat-related incident. If a WBGT meter or records are not available, Argonne National Laboratory (ANL) developed a utility (i.e. calculator) that uses literature-supported algorithmic equations to determine WBGT from current or historic weather data available on the internet. The calculator uses an outdoor wet bulb globe temperature model described by Dr. James C. Liljegren in August 2008.

The calculator is available as a downloadable zip file at http://www.osha.gov/dts/osta/otm/otm_iii/wbgtutil.zip. If installing this software on a federal agency computer, coordinate with your system administrator. The ANL WBGT Calculator, which is copyrighted, requires users to follow the open source license redistribution contingencies included as an appendix in this chapter.

The ANL WBGT Calculator uses the following information to determine WBGT:

- Air Temperature, °F or °C

- Solar Irradiance, W/m2

- Wind Speed, mph or m/s

- Relative Humidity, %

- Date and time

- Barometric Pressure, inches of Hg or millibars

-

Longitude and latitude, enter on the "Options" page

The data entered into the ANL WBGT Calculator determines the accuracy of the WBGT calculations. A calculated WBGT is more accurate when the data source (e.g., weather station) has similar direct sun, humidity, and wind speed as the worksite. If time, date, longitude, latitude or barometric pressure is not accurate, then the WBGT calculation adjustments will not be accurate. For example, the ANL WBGT Calculator uses the date and time, longitude, latitude and barometric pressure to adjust irradiance before calculating the WBGT.

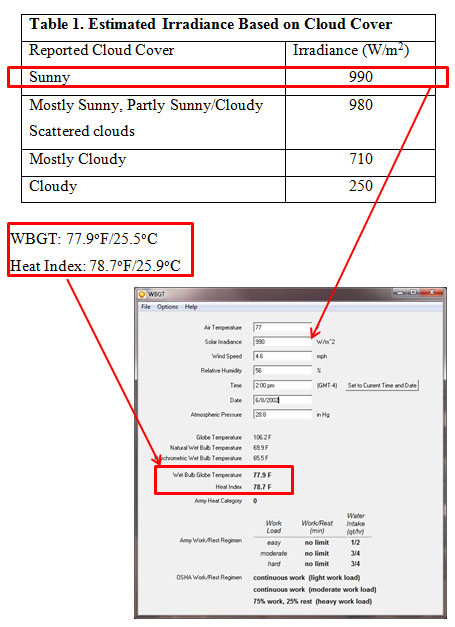

Using the most conservative values when weather data is unknown will provide a baseline understanding about heat stress in the environment under the best possible conditions for that day. For example, if using the lowest likely estimated W/m2 for solar irradiance in the calculator indicates there is a heat hazard, then the assumption can be made that there is also a heat hazard if the solar irradiance is higher. Table 1 provides some estimated irradiance values based on cloud cover using an equation published in the 2013 Energy Procedia, Volume 42 Page 406-415 article, "Estimation of Global Solar Radiation Using Three Simple Methods," by A. Ben Jemaa, et al. These solar irradiance estimates are approximately correct if the sun is directly overhead. Solar irradiance is lower in other situations (e.g., morning, afternoon, at higher latitudes, and at certain times of year). Please refer to the SHTP on Occupational Heat Illness for an alternative calculator that includes these variables.

Table 1. Estimated Irradiance Based on Cloud Cover Reported Cloud Cover Irradiance (W/m2) Sunny 990 Mostly Sunny, Partly Sunny/Cloudy

Scattered Clouds980 Mostly Cloudy 710 Cloudy 250 Certified Weather Data

The NWS will provide certified weather data. Just send a request that includes data for two days prior to the event, specific daily forecasts, alerts and special weather statements, including heat waves or high heat indices notifications to:

- National Centers for Environmental Information

- Center for Weather and Climate

- 151 Patton Avenue

- Asheville, NC 28801

Weather data is available for current conditions and historic conditions through the National Weather Service or the following other sources:

- The National Climatic Data Center (NCDC) officially archives National Weather Service (NWS)

- Archived 5-minute weather data recorded by the National Weather Service

- Recent hourly weather data for the past 72 hours

-

Other public weather observation sites such as Intellicast and Weather Underground

The information regarding application of the ACGIH® Heat Stress and Strain TLV® is copyrighted by ACGIH® and is not publicly available. It may be accessed on the ACGIH® website subject to their permissions of use. OSHA personnel are directed to access OSHA’s intranet for more information.

V.

VI. Example Problem

The following is an example using the WBGT Calculator post-incident to determine if there was potentially a heat hazard present during an incident. The details are based on a real incident discussed in the NIOSH Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments.

As thoroughly as possible, determine if there were heat hazards present in the following example.

Example: In Toledo, Ohio, on June 8, 2002, at 4 pm, a 30-year-old male landscaper mowing-assistant collapsed and died of heat stroke after a day of caring for residential lawns [NIOSH 2002].

Post-incident interviews indicate the worker complained of feeling light-headed and short of breath two hours before his death, but he refused assistance offered to him by his partner. Others said that the worker was on medication that had a warning about exposure to extreme heat, and this might have interfered with body temperature regulation.

The landscape worker was wearing two pairs of work pants on the day he died, but his partner did not notice any profuse sweating or flushed or extremely dry skin. Interviews with the emergency responders indicate that when the worker collapsed, emergency medical services (EMS) treated the victim at the site, and then transported him to the hospital. At the hospital he was pronounced dead with an internal temperature of 42°C (107.6°F).

Answer:

Since wind, humidity, and barometric pressure site measurements are not given in this example problem, the historical data was found online at Weather Underground by entering the location and date.

Screenshot of the Historial Weather screen on the Weather Underground website. Includes a description: 'Find historical weather by searching for a city, zip code, or aiport code. Include a data for which you would like to see weather history. You can select a range of dates in the results on the next page.' Followed by some input options for Location: City, State or ZIP Code, or Airport Code and Date: Month, Day, Year.

Given and Assumptions

- Date of Incident: June 8, 2002

- Air Temperature: 77°F (25°C) – From Weather Underground

- Cloud Cover: Clear – From Weather Underground

- Wind Speed: 4.6 mph – From Weather Underground

- Relative Humidity: 56% - From Weather Underground

- Time: 2 pm The worker's symptoms began two hours before his death at 4:00 pm

- Barometric Pressure: 30.13 in Hg - From Weather Underground

- Clothing Adjustment Factor (CAF): 3 – From Table 3

Step 1: Determine WBGT

Use historic weather data and enter it into the Argonne National Laboratory WBGT estimation calculator.

Using Table 1, solar irradiance for clear/sunny may be estimated as 990 W/m2

Screenshot of Table 1. Estimated Irradiance Based on Cloud Cover. Table includes two columns, one for Reported Cloud Cover and the other for Irradiance (W/m2) -- Sunny-990, Mostly Sunny, Partly Sunny/Cloudy Scattered clouse-980, Mostly Cloudy-710, Cloudy-250. Also, includes a screen capture from the WBGT tool with example information as it would pertain to the Sunny-990 estimated irradiance.

The information regarding application of the ACGIH® Heat Stress and Strain TLV® is copyrighted by ACGIH® and is not publicly available. It may be accessed on the ACGIH® website subject to their permissions of use. OSHA personnel are directed to access OSHA’s intranet for more information.

VII. References

A. Ben Jemaa, S. Rafa, N. Essounbouli, A. Hamzaoui, F. Hnaien et F. Yalaoui. Estimation of Global Solar Radiation Using Three Simple Methods. Energy Procedia, Volume 42 Page 406-415, 2013.

American Conference of Governmental Industrial Hygienists (ACGIH). Heat Stress and Strain: TLV® Physical Agents 7th Edition Documentation (2017). TLVs and BEIs with 7th Edition Documentation, CD-ROM. Cincinnati, OH, 2017.

Argonne National Laboratory (ANL). Wet Bulb Globe Temperature (WBGT) Version 1.2. Chicago, IL, 2008.

R. Liljegren, R. Carhart, P. Lawday, S. Tschopp, R. Sharp. Modeling the Wet Bulb Globe Temperature Using Standard Meteorological Measurements. Journal of Occupational and Environmental Hygiene, 5:10, 645-655, 2008.

Occupational Safety and Health Administration (OSHA). Recommended Practices for Safety and Health Programs. Publication OSHA 3885, October 2016.

National Institute for Occupational Safety and Health (NIOSH). Criteria for a Recommended Standard: Occupational Exposure to Heat and Hot Environments. DHHS (NIOSH) Publication No. 2016-106, February 2016.

National Institute for Occupational Safety and Health (NIOSH). Landscape mowing assistant dies from heat stroke. Fatality Assessment and Control Evaluation (FACE) Investigation Report No. 02-MI-75-01. Cincinnati, OH, 2002.

Appendix A: Copyright for Liljegren, Argonne National Laboratory WBGT Utility

Copyright© 2008, UChicago Argonne, LLC

All Rights Reserved

Wet Bulb Globe Temperature (WBGT), Version 1.2

Author: James Liljegren, Argonne National Laboratory, DIS Division

OPEN SOURCE LICENSE

Redistribution and use in source and binary forms, with our without modification, are permitted provided that the following conditions are met:

- Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer. Software changes, modifications, or derivative works, should be noted with comments and the author and organization's name.

- Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the documentation and/or other materials provided with the distribution.

- Neither the names of UChicago Argonne, LLC or the Department of Energy nor the names of its contributors may be used to endorse or promote products derived from this software without specific prior written permission.

- The software and the end-user documentation included with the redistribution, if any, must include the following acknowledgment: "This product includes software produced by UChicago Argonne, LLC under Contract No. DE-AC02-06CH11357 with the Department of Energy."

**************************************************************************

DISCLAIMER

THE SOFTWARE IS SUPPLIED "AS IS" WITHOUT WARRANTY OF ANY KIND.

NEITHER THE UNITED STATES GOVERNMENT, NORE THE UNITED STATES DEPARTMENT OF ENERGY, NOR UCHICAGO ARGONNE, LLC, NORE ANY OF THEIR EMPLOYEES, MAKES ANY WARRANTY, EXPRESS OR IMPLED, OR ASSUMES ANY LEGAL LIABILITY OR REPONSIBLITY FOR THE ACCURACY, COMPLETENESS, OR USEFULNESS OF ANY INFORMATION, DATA, APPARATUS, PRODUCT, OR PROCESS DISCLOSED, OR REPRESENTS THAT ITS USE WOULD NOT INFRINGE PRIVATELY OWNED RIGHTS.