Shipyard Employment eTool

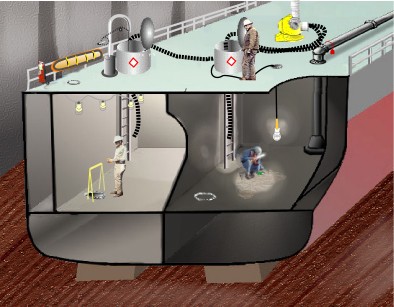

PPE Selection >> Workers in Confined or Enclosed Spaces and Other Dangerous Atmospheres

The OSHA Hierarchy of Controls

- Engineering Controls

- Administration Controls

- Personal Protective Equipment (PPE)

After the initial entry testing has been completed by the Shipyard Competent Person or Marine Chemist, appropriate PPE must be selected for the workers. PPE selection is based on hazard assessment, results of initial testing, and type of work to be conducted.

Periodic retesting may be required, depending on operations and space conditions.

In addition to typical shipyard PPE, if there are toxic or corrosive coatings or residues, shipyard personnel may specify additional protective clothing and respiratory protection. In ship repair, there are specific PPE requirements for operations, such as asbestos, lead, or cadmium removal.

- General Shipyard Worker PPE

- Protective clothing, gloves and boots

- Respiratory protection

- Personal Fall Protection Equipment

Typical PPE for shipyard workers includes:

- Hard hat,

- Safety glasses,

- Safety boots (hard toed),

- Gloves,

- Sleeved shirt,

- Long pants (no shorts or cut-offs),

- Hearing protection, and

- Flashlight or lightstick.

This equipment is for the protection of the worker entering confined or enclosed spaces from toxic or corrosive residues or sludge that are present on decks, ladders, or bulkheads that may contact with their clothing or skin. The identification of these materials is important so that the appropriate PPE may be selected, including:

- Disposable coveralls

- Chemical-resistant coveralls

- Water-resistant clothing (such as rain gear)

- Chemical-resistant gloves

- Chemical-resistant boots

For more detailed information, review Hand and Body Protection.

In addition to the general shipyard PPE, respiratory protection may also be required. The following apply to work in enclosed and confined spaces:

- The appropriate respiratory protection for the worker must be established by air monitoring or work to be preformed to determine the identification and concentration of air contaminants. [29 CFR 1915.12]

- Consideration should be given to previous contents (for example cargo, fuel, oxidation/rust, etc.) as well as other environmental hazards.

- Supplied air respirators may be required if the concentration of toxic vapors, oxygen, or toxic gases are unknown or at IDLH levels. If this is the case, a buddy system is required. [29 CFR 1910.134(d)(2)]

- Work with lead, asbestos, and cadmium have specific respiratory protection requirements.

For more detailed information, review Respiratory Protection.