Powered Industrial Trucks (Forklift) eTool

Operating the Forklift » Pre-Operation

A vehicle that is in need of repair, defective or in any way unsafe should be removed from service. The problem should be recorded on a log and reported to a supervisor immediately. This section discusses pre-operation and operational inspections that operators should perform to ensure that forklifts will operate safely. Only operators who have been trained and evaluated in accordance with 29 CFR 1910.178(l) can operate forklifts.

Note: For a brief overview of measurements that forklift operators should know to determine whether the forklift can do a task safely in the available space, see Critical Forklift Measurements.

Requirements and Recommended Practices:

OSHA requires that all forklifts be examined at least daily before being placed in service. Forklifts used on a round-the-clock basis must be examined after each shift. [29 CFR 1910.178(q)(7)]

The operator should conduct a pre-start visual check with the key off and then perform an operational check with the engine running. The forklift should not be placed in service if the examinations show that the vehicle may not be safe to operate.

Remember! A vehicle in need of repair, defective or in any way unsafe, should not be driven and should be taken out of service immediately. Any problems should be recorded on the appropriate documents and reported to a supervisor.

-

Before starting your vehicle, conduct a pre-operation (or pre-start) inspection that checks a variety of items, including but not limited to:

-

Fluid levels -- oil, water, and hydraulic fluid.

-

Leaks, cracks or any other visible defect including hydraulic hoses and mast chains. NOTE: Operators should not place their hands inside the mast. Use a stick or other device to check chain tension.

-

Tire condition and pressure including cuts and gouges.

-

Condition of the forks, including the top clip retaining pin and heel.

-

Load backrest extension.

-

Finger guards.

-

Safety decals and nameplates. Ensure all warning decals and plates are in place and legible. Check that information on the nameplate matches the model and serial numbers and attachments.

-

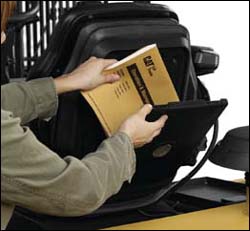

Operator manual on truck and legible.

-

Operator compartment. Check for grease and debris.

-

All safety devices are working properly including the seat belt.

-

In addition to this general inspection, additional items should be checked depending on the forklift type (electric or internal combustion, including liquid propane). These include but are not limited to:

Additional Information

-

Electric Forklifts

-

Cables and connectors for frayed or exposed wires

-

Battery restraints

-

Electrolyte levels

-

Hood latch

-

-

Internal Combustion Forklifts

-

Engine oil

-

Brake reservoir

-

Engine coolant

-

Air filter

-

Belts and hoses

-

Radiator

-

Hood latch

-

-

Liquid Propane Forklifts

-

Properly mounted tank

-

Pressure relief valve pointing up

-

Hose and connectors

-

Tank restraint brackets

-

Tank for dents and cracks

-

Tank fits within profile of truck

-

Leaks

-

Additional Information

-

Sample Daily Checklists for Powered Industrial Trucks. Note: Checklists are provided as a guide only and are not a substitute for complying with OSHA standards.

After completing the pre-operation inspection, operators should conduct an operational inspection with the engine running. This inspection includes:

-

Accelerator linkage

-

Inch control (if equipped)

-

Brakes

-

Steering

-

Drive control: forward and reverse

-

Tilt control: forward and back

-

Hoist and lowering control

-

Attachment control

-

Horn

-

Lights

-

Back-up alarm (if equipped)

-

Hour meter

Additional Information

-

Sample Daily Checklists for Powered Industrial Trucks. Note: Checklists are provided as a guide only and are not a substitute for complying with OSHA standards.

Potential Hazards

While driving, be aware of these potential hazards:

-

Mechanical breakdown

-

Fire

-

Overheating

-

Leakage

Requirements and Recommended Practices

The OSHA powered industrial truck standard [29 CFR 1910.178] lists a number of conditions under which a forklift must be removed from service. If the operator notes these conditions while driving, the operator must stop, park the vehicle and get assistance.

-

Any powered industrial truck not in safe operating condition shall be removed from service. All repairs shall be made by authorized personnel. [29 CFR 1910.178(q)(1)]

-

Defects when found must be immediately reported and corrected. [29 CFR 1910.178(q)(7)]

-

Any vehicle that emits hazardous sparks or flames from the exhaust system shall immediately be removed from service, and not returned to service until the cause for the emission of such sparks and flames has been eliminated. [29 CFR 1910.178(q)(8)]

-

When the temperature of any part of any truck is found to be in excess of its normal operating temperature, thus creating a hazardous condition, the vehicle shall be removed from service and not returned to service until the cause for such overheating has been eliminated. [29 CFR 1910.178(q)(9)]

-

No truck shall be operated with a leak in the fuel system until the leak has been corrected. [29 CFR 1910.178(p)(4)]

Scheduled maintenance is critically important to the safe operation of your vehicle. Never operate a forklift requiring maintenance, and always report repair problems to your supervisor. Follow your company's procedures.

Potential Hazards:

-

Forklift skidding or sliding due to grease, leakage, spills.

-

Mechanical breakdown due to poor maintenance.

-

Accidents and injuries due to improperly working equipment.

Requirements and Recommended Practices:

- Never operate a vehicle that requires maintenance or is in any way unsafe. [29 CFR 1910.178(p)(1)]

-

Remove from service any powered industrial truck not in safe operating condition. All repairs must be made by authorized personnel. Do not attempt to fix it yourself unless you are trained and authorized to do so. [29 CFR 1910.178(q)(1)]

-

Perform preventive maintenance according to manufacturer's scheduled recommendations.

-

Keep industrial truck in clean condition, free of lint, excess oil, and grease. [29 CFR 1910.178(q)(10)]

-

Use non-combustible agents for cleaning trucks.

-

High flash point (at or above 100° F) solvents may be used. Do not use low flash point (below 100° F) solvents.

-

Take recommended precautions regarding toxicity, ventilation and fire hazards.

-

-

For more information on battery maintenance, see the Battery Maintenance section of the Power Sources: Electric page.