QuickTakes Newsletter

January 30, 2026

TAKING CHARGE OF SAFETY

OSHA has issued a new letter of interpretation on recordkeeping requirements, highlighting the growing need for understanding safety risks associated with lithium-ion batteries in the workplace. These batteries are widely used but can pose safety and health risks to workers during manufacturing, everyday use, emergency response, disposal, and recycling. Potential risks include fires, explosions, and exposure to harmful chemicals.

Employers can help reduce these dangers by taking practical safety steps such as:

- Implementing hazard controls during battery design and production

- Ensuring proper ventilation

- Storing batteries in cool, dry locations

- Monitoring storage areas for flammable or toxic gases

- Using designated recycling facilities for disposal

- Providing safety showers and eyewash stations when handling battery materials.

To learn more, read our fact sheet on safety practices related to lithium-ion batteries, and visit OSHA's Letters of Interpretation webpage for more official guidance about how to comply with safety requirements in specific workplace situations.

UPCOMING EVENTS

February 1: Employers must post their 300A summary of injuries and illnesses recorded in 2025 at your workplace until April 30, where it will be visible to all employees.

February 24: Temporary Workers in the Construction Industry webinar.

March 2: The deadline for covered employers to submit calendar year 2025 injury and illness data through the Injury Tracking Application (ITA).

April 23 at 1:00 p.m. ET: Workers Memorial Day Ceremonies

April 23, 7:00 p.m. ET: Workers Memorial Candlelight Vigil

Do you have a public safety and health event, training or webinar that you’d like to have featured in QuickTakes. Please share event information with us including the date, time, location, and short description.

OSHA PRIORITIES

Have a minute? Watch this short video to hear about OSHA's top priorities for addressing hazards and how we're here to support workers and employers in identifying hazards and improving safety.

ALLIES FOR YOUNG WORKERS

Watch this video to learn how the Career and Technical Education Center of Idaho Falls and OSHA are working together to strengthen safety and health education, empower students, and build safer American workplaces through collaboration and training. It also highlights the importance of OSHA 10-Hour courses in preventing injuries and illnesses and strengthening relationships with regional OSHA offices to better protect and prepare young people entering the workforce. Visit our website to learn more about OSHA's Alliance Program.

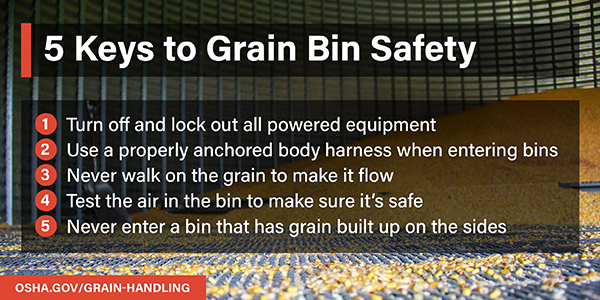

GRAIN BIN SAFETY

GRAIN SAFETY

5 Keys to Grain Bin Safety

- Turn off and lock out all powered equipment

- Use a properly anchored body harness when entering bins

- Never walk on the grain to make it flow

- Test the air in the bin to make sure it’s safe

- Never enter a bin that has grain built up on the sides

SHARING SAFETY CONCERNS

OSHA investigators found that a Texas trucking company wrongly terminated a driver for raising safety concerns. This was a violation of the Surface Transportation Assistance Act, which protects commercial motor vehicle safety complaints. OSHA’s Whistleblower Protection Programs enforces 25 whistleblower statutes that protect employees from retaliation for reporting potential violations involving safety, health, environmental protection, and other public interest concerns. Visit whistleblowers.gov to learn more.

YOU ASK...WE ANSWER

❓ Where can I find OSHA resources on training?

🗣️ OSHA offers a variety of resources to help employers and workers learn how to stay safe and healthy on the job:

- Visit our Training webpage to find information on in-person and online courses offered by OSHA Training Institute Education Centers.

- Watch our videos that cover training topics such as trenching, confined spaces, fall protection and controlling respirable silica.

- Download our publications for guidance on OSHA training requirements and how to meet them.

WHAT’S TRENDING

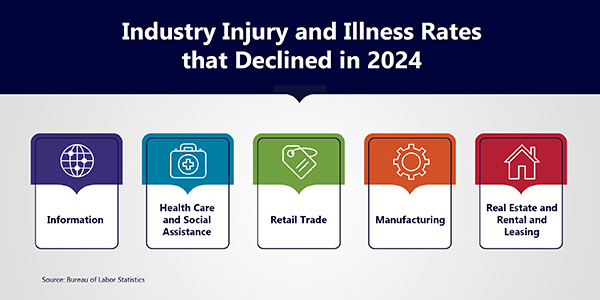

New data from the Bureau of Labor Statistics shows that in 2024, private industry employers reported the lowest number of nonfatal injuries and illnesses in more than 20 years. The incidence rate of recordable injuries and illnesses did not increase in any industry sectors, but decreased in five of them: information, health care and social assistance, retail trade, manufacturing, and real estate and rental and leasing.

Real progress can be made when we all work together. That's why we are committed to working with employers and workers to prevent injuries and illnesses in all industries. We remain committed to partnering with employers and workers in all industries to reduce injuries and illnesses and keep workers safe.

Answer to last issue’s What’s Trending question:

How many trenching hazards can you spot in this photo?

- Heavy loader is dumping soil at the top edge of the trench while workers are in it.

- Dirt piles and equipment are too near the trench rim, increasing collapse risk.

- There is no ladder or other easily accessible means available for workers to exit trench

- There are no barricades, guardrails, or warning signs around the trench to protect personnel or passing equipment.

- No appropriate protective system - trench box, shoring, or properly sloped/benched sides - is in place to prevent trench walls from collapsing.

Visit our trenching and excavations webpage to learn how to protect workers from these and other hazards.

Industry injury and Illness rates that declined in 2024

Information

health care and social assistance

retail trade

manufacturing

real estate and rental and leasing

Source: Bureau of Labor Statistics

QuickTakes subscribers occasionally receive DYK? bulletins about a single timely topic, resource or upcoming event.