Steel Erection eTool

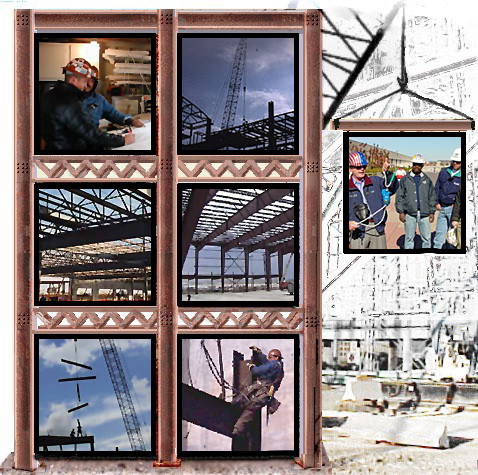

Despite being covered since 1971 under the original steel erection standard, America's 56,000 steel erectors continue to suffer 35 fatal accidents per year, a rate of one death per 1,600 workers. OSHA estimates that 30 of those deaths, as well as nearly 1,150 annual lost-workday injuries, will be averted by compliance with provisions of the standard, developed with industry and labor through negotiated rulemaking. To that end, this eTool* has been created to educate employers and workers about the revised standard (Subpart R).

The standard is intended to protect employees from steel erection hazards when involved in the construction, alteration, or repair of:

- Single-story buildings

- Multi-story buildings

- Bridges

- Other structures where steel erection occurs

The requirements apply to all employers engaged in steel erection unless otherwise specified. It does not cover electrical transmission towers, communication and broadcast towers, or tanks.

For examples of steel erection activities and/or activities covered by the steel erection standard when they occur during and as a part of steel erection activities, see the Scope section.

See OSHA's Workers' Rights page for more information on rights and protections.

*eTools are stand-alone, interactive, highly illustrated web-based training tools on occupational safety and health topics. Some use expert system modules, which enable users to answer questions and receive reliable advice on how OSHA regulations apply to their work site. Some provide guidance information for developing a comprehensive safety and health program and include other recommended practices that often go beyond specific OSHA requirements. As indicated in the disclaimer, eTools do not create new OSHA requirements.