GUIDANCE ON SAFE SLING USE

Tables and Figures

| Nominal Chain Size | Single Leg Slings | Double Leg Bridle Slings Single Basket Slings | Triple and Quadruple Leg Bridle Slings Double Basket Slings | |||||

|---|---|---|---|---|---|---|---|---|

|

|

|||||||

| Horizontal Angle [Note 1] | ||||||||

| 90° | 60° | 45° | 30° | 60° | 45° | 30° | ||

| in | mm | lb | lb | lb | lb | lb | lb | lb |

| 7/32 | 5.5 | 2,100 | 3,600 | 3,000 | 2,100 | 5,500 | 4,400 | 3,200 |

| 9/32 | 7 | 3,500 | 6,100 | 4,900 | 3,500 | 9,100 | 7,400 | 5,200 |

| 5/16 | 8 | 4,500 | 7,800 | 6,400 | 4,500 | 11,700 | 9,500 | 6,800 |

| ⅜ | 10 | 7,100 | 12,300 | 10,000 | 7,100 | 18,400 | 15,100 | 10,600 |

| ½ | 13 | 12,000 | 20,800 | 17,000 | 12,000 | 31,200 | 25,500 | 18,000 |

| ⅝ | 16 | 18,100 | 31,300 | 25,600 | 18,100 | 47,000 | 38,400 | 27,100 |

| ¾ | 20 | 28,300 | 49,000 | 40,000 | 28,300 | 73,500 | 60,000 | 42,400 |

| ⅞ | 22 | 34,200 | 59,200 | 48,400 | 34,200 | 88,900 | 72,500 | 51,300 |

| 1 | 26 | 47,700 | 82,600 | 67,400 | 47,700 | 123,900 | 101,200 | 71,500 |

| 1-¼ | 32 | 72,300 | 125,200 | 102,200 | 72,300 | 187,800 | 153,400 | 108,400 |

NOTES:

(1) The horizontal angle is the angle formed between the inclined leg and the horizontal plane [see figure 1(d)].

| Nominal Chain Size | Single Leg Slings | Double Leg Bridle Slings Single Basket Slings | Triple and Quadruple Leg Bridle Slings Double Basket Slings | |||||

|---|---|---|---|---|---|---|---|---|

|

|

|||||||

| Horizontal Angle [Note 1] | ||||||||

| 90° | 60° | 45° | 30° | 60° | 45° | 30° | ||

| in | mm | lb | lb | lb | lb | lb | lb | lb |

| 7/32 | 5.5 | 2,700 | 4,700 | 3,800 | 2,700 | 7,000 | 5,700 | 4,000 |

| 9/32 | 7 | 4,300 | 7,400 | 6,100 | 4,300 | 11,200 | 9,100 | 6,400 |

| 5/16 | 8 | 5,700 | 9,900 | 8,100 | 5,700 | 14,800 | 12,100 | 8,500 |

| ⅜ | 10 | 8,800 | 15,200 | 12,400 | 8,800 | 22,900 | 18,700 | 13,200 |

| ½ | 13 | 15,000 | 26,000 | 21,200 | 15,000 | 39,000 | 31,800 | 22,500 |

| ⅝ | 16 | 22,600 | 39,100 | 32,000 | 22,600 | 58,700 | 47,900 | 33,900 |

| ¾ | 20 | 35,300 | 61,100 | 49,900 | 35,300 | 91,700 | 74,900 | 53,000 |

| ⅞ | 22 | 42,700 | 74,000 | 60,400 | 42,700 | 110,900 | 90,600 | 64,000 |

NOTES:

(1) The horizontal angle is the angle formed between the inclined leg and the horizontal plane [see figure 1(d)].

| Nominal Chain Size | Single Leg Slings | Double Leg Bridle Slings Single Basket Slings | Triple and Quadruple Leg Bridle Slings Double Basket Slings | |||||

|---|---|---|---|---|---|---|---|---|

|

|

|

||||||

| Horizontal Angle [Note 1] | ||||||||

| 90° | 60° | 45° | 30° | 60° | 45° | 30° | ||

| in | mm | lb | lb | lb | lb | lb | lb | lb |

| 7/32 | 5.5 | 1,700 | 2,900 | 2,400 | 1,700 | 4,400 | 3,500 | 2,600 |

| 9/32 | 7 | 2,800 | 5,000 | 3,900 | 2,800 | 7,300 | 5,900 | 4,200 |

| 5/16 | 8 | 3,600 | 6,200 | 5,100 | 3,600 | 9,300 | 7,600 | 5,400 |

| ⅜ | 10 | 5,700 | 9,800 | 8,000 | 5,700 | 14,700 | 12,100 | 8,500 |

| ½ | 13 | 9,600 | 16,600 | 13,600 | 9,600 | 25,000 | 20,400 | 14,400 |

| ⅝ | 16 | 14,500 | 25,000 | 20,500 | 14,500 | 37,600 | 30,700 | 21,700 |

| ¾ | 20 | 22,600 | 39,200 | 32,000 | 22,600 | 58,800 | 48,000 | 33,900 |

| ⅞ | 22 | 27,400 | 47,400 | 38,700 | 27,400 | 71,100 | 58,000 | 41,000 |

| 1 | 26 | 38,200 | 66,100 | 53,900 | 38,200 | 99,100 | 81,000 | 57,200 |

| 1-¼ | 32 | 57,800 | 100,200 | 81,800 | 57.800 | 150,200 | 122,700 | 86,700 |

NOTES:

(1) The horizontal angle is the angle formed between the inclined leg and the horizontal plane [see figure 1(d)].

(2) Rated loads are for angles of choke greater than 120 degrees.

| Nominal Chain Size | Single Leg Slings | Double Leg Bridle Slings Single Basket Slings | Triple and Quadruple Leg Bridle Slings Double Basket Slings | |||||

|---|---|---|---|---|---|---|---|---|

|

|

|

||||||

| Horizontal Angle [Note 1] | ||||||||

| 90° | 60° | 45° | 30° | 60° | 45° | 30° | ||

| in | mm | lb | lb | lb | lb | lb | lb | lb |

| 7/32 | 5.5 | 2,100 | 3,600 | 3,000 | 2,100 | 5,500 | 4,400 | 3,200 |

| 9/32 | 7 | 3,500 | 6,100 | 4,900 | 3,500 | 9,100 | 7,400 | 5,200 |

| 5/16 | 8 | 4,500 | 7,800 | 6,400 | 4,500 | 11,700 | 9,500 | 6,800 |

| ⅜ | 10 | 7,100 | 12,300 | 10,000 | 7,100 | 18,400 | 15,100 | 10,600 |

| ½ | 13 | 12,000 | 20,800 | 17,000 | 12,000 | 31,200 | 25,500 | 18,000 |

| ⅝ | 16 | 18,100 | 31,300 | 25,600 | 18,100 | 47,000 | 38,400 | 27,100 |

| ¾ | 20 | 28,300 | 49,000 | 40,000 | 28,300 | 73,500 | 60,000 | 42,400 |

| ⅞ | 22 | 34,200 | 59,200 | 48,400 | 34,200 | 88,900 | 72,500 | 51,300 |

NOTES:

(1) The horizontal angle is the angle formed between the inclined leg and the horizontal plane [see figure 1(d)].

(2) Rated loads are for angles of choke greater than 120 degrees.

| Temperature | Grade of Chain | ||||

|---|---|---|---|---|---|

| Grade 80 | Grade 100 | ||||

| (°F) | (°C) | Temporary Reduction of Rated Load WHILE AT Temperature | Permanent Reduction of Rated Load AFTER EXPOSURE to Temperature | Temporary Reduction of Rated Load WHILE AT Temperature | Permanent Reduction of Rated Load AFTER EXPOSURE to Temperature |

| Below 400 |

Below 204 |

NONE | NONE | NONE | NONE |

| 400 | 204 | 10% | None | 15% | None |

| 500 | 260 | 15% | None | 25% | 5% |

| 600 | 316 | 20% | 5% | 30% | 15% |

| 700 | 371 | 30% | 10% | 40% | 20% |

| 800 | 427 | 40% | 15% | 50% | 25% |

| 900 | 482 | 50% | 20% | 60% | 30% |

| 1000 | 538 | 60% | 25% | 70% | 35% |

| Over 1000 |

Over 538 |

REMOVE FROM SERVICE | |||

| Nominal Chain or Coupling Link Size | Minimum Allowable Thickness at Any Point on The Link | ||

|---|---|---|---|

| In | Mm | In | mm |

| 7/32 | 5.5 | 0.189 | 4.80 |

| 9/32 | 7 | 0.239 | 6.07 |

| 5/16 | 8 | 0.273 | 6.93 |

| 3/8 | 10 | 0.342 | 8.69 |

| 1/2 | 13 | 0.443 | 11.26 |

| 5/8 | 16 | 0.546 | 13.87 |

| 3/4 | 20 | 0.687 | 17.45 |

| 7/8 | 22 | 0.750 | 19.05 |

| 1 | 26 | 0.887 | 22.53 |

| 1 1/4 | 32 | 1.091 | 22.71 |

| Hitch Type | Single-Leg | Two-Leg Bridle | Choker | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

||||||||||||||

| Horizontal Angle | Horizontal Angle | |||||||||||||||||

| Vertical | Choker | Vertical Basket | Vertical | 60° | 45° | 30° | 60° | |||||||||||

| Rope Diameter, in. | HT | MS | S | HT&MS | HT | MS | S | HT | MS | S | HT | MS | HT | MS | HT | MS | HT&MS | HT&MS |

| ¼ | 0.54 | 0.56 | 0.60 | 0.42 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 0.94 | 0.97 | 0.77 | 0.79 | 0.54 | 0.56 | 0.73 | 0.42 |

| 5/16 | 0.83 | 0.87 | 0.94 | 0.66 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.4 | 1.5 | 1.2 | 1.2 | 0.83 | 0.87 | 1.1 | 0.66 |

| ⅜ | 1.2 | 1.2 | 1.3 | 0.94 | 2.4 | 2.5 | 2.5 | 2.4 | 2.5 | 2.5 | 2.0 | 2.2 | 1.7 | 1.8 | 1.2 | 1.2 | 1.6 | 0.94 |

| 7/16 | 1.6 | 1.7 | 1.8 | 1.3 | 3.2 | 3.4 | 3.4 | 3.2 | 3.4 | 3.4 | 2.7 | 2.9 | 2.2 | 2.4 | 1.6 | 1.7 | 2.2 | 1.3 |

| ½ | 2.0 | 2.2 | 2.4 | 1.6 | 4.0 | 4.4 | 4.4 | 4.0 | 4.4 | 4.4 | 3.5 | 3.8 | 2.9 | 3.1 | 2.0 | 2.2 | 2.9 | 1.6 |

| 9/16 | 2.5 | 2.7 | 3.0 | 2.1 | 5.0 | 5.5 | 5.5 | 5.0 | 5.5 | 5.5 | 4.4 | 4.8 | 3.6 | 3.9 | 2.5 | 2.7 | 3.6 | 2.1 |

| ⅝ | 3.1 | 3.4 | 3.7 | 2.6 | 6.2 | 6.8 | 6.8 | 6.2 | 6.8 | 6.8 | 5.3 | 5.9 | 4.4 | 4.8 | 3.1 | 3.4 | 4.5 | 2.6 |

| ¾ | 4.3 | 4.8 | 5.2 | 3.7 | 8.6 | 9.7 | 9.7 | 8.6 | 9.7 | 9.7 | 7.4 | 8.4 | 6.1 | 6.8 | 4.3 | 4.8 | 6.3 | 3.7 |

| ⅞ | 5.7 | 6.6 | 7.1 | 5.0 | 11 | 13 | 13 | 11 | 13 | 13 | 9.8 | 11 | 8.0 | 9.3 | 5.7 | 6.6 | 8.6 | 5.0 |

| 1 | 7.4 | 8.3 | 9.2 | 6.4 | 15 | 17 | 17 | 15 | 17 | 17 | 13 | 14 | 10 | 12 | 7.4 | 8.3 | 11 | 6.4 |

| 1 ⅛ | 9.3 | 10 | 12 | 8.1 | 19 | 21 | 21 | 19 | 21 | 21 | 16 | 18 | 13 | 15 | 9.3 | 10 | 14 | 8.1 |

| 1 ¼ | 11 | 13 | 14 | 9.9 | 23 | 26 | 26 | 23 | 26 | 26 | 20 | 22 | 16 | 18 | 11 | 13 | 17 | 9.9 |

GENERAL NOTES:

HT = hand-tucked splice.

MS = mechanical splice.

S = swaged or poured socket.

Rated loads based on minimum D/d ratio of 25/1.

(e) Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(f) For choker hitch, the angle of choke is 120 deg or greater.

| Hitch Type | Three-Leg | Four-Leg | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||||||||

| Horizontal Angle | Horizontal Angle | |||||||||||||||

| Vertical | 60 deg | 45 deg | 30 deg | Vertical | 60 deg | 45 deg | 30 deg | |||||||||

| Rope Diameter, in. | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS |

| ¼ | 1.6 | 1.7 | 1.4 | 1.4 | 1.2 | 1.2 | 0.81 | 0.84 | 2.2 | 2.2 | 1.9 | 1.9 | 1.5 | 1.6 | 1.1 | 1.1 |

| 5/16 | 2.5 | 2.6 | 2.2 | 2.3 | 1.8 | 1.8 | 1.3 | 1.3 | 3.3 | 3.5 | 2.9 | 3.0 | 2.4 | 2.5 | 1.7 | 1.7 |

| ⅜ | 3.5 | 3.7 | 3.1 | 3.2 | 2.5 | 2.6 | 1.8 | 1.9 | 4.7 | 5.0 | 4.1 | 4.3 | 3.3 | 3.5 | 2.4 | 2.5 |

| 7/16 | 4.7 | 5.0 | 4.1 | 4.4 | 3.4 | 3.6 | 2.4 | 2.5 | 6.3 | 6.7 | 5.5 | 5.8 | 4.5 | 4.8 | 3.2 | 3.4 |

| ½ | 6.1 | 6.5 | 5.3 | 5.7 | 4.3 | 4.6 | 3.0 | 3.3 | 8.1 | 8.7 | 7.0 | 7.5 | 5.7 | 6.2 | 4.0 | 4.4 |

| 9/16 | 7.6 | 8.2 | 6.6 | 7.1 | 5.4 | 5.8 | 3.8 | 4.1 | 10 | 11 | 8.7 | 9.5 | 7.1 | 7.8 | 5.0 | 5.5 |

| ⅝ | 9.8 | 10 | 8.0 | 8.8 | 6.5 | 7.2 | 4.6 | 5.1 | 12 | 14 | 11 | 12 | 8.7 | 9.6 | 6.2 | 6.8 |

| ¾ | 13 | 15 | 11 | 13 | 9.1 | 10 | 6.4 | 7.3 | 17 | 19 | 15 | 17 | 12 | 14 | 8.5 | 9.7 |

| ⅞ | 17 | 20 | 15 | 17 | 12 | 14 | 8.5 | 9.8 | 23 | 26 | 20 | 23 | 16 | 19 | 11 | 13 |

| 1 | 22 | 25 | 19 | 22 | 16 | 18 | 11 | 12 | 29 | 33 | 25 | 29 | 21 | 23 | 15 | 17 |

| 1 ⅛ | 28 | 31 | 24 | 27 | 20 | 22 | 14 | 16 | 37 | 42 | 32 | 36 | 26 | 29 | 19 | 21 |

| 1 ¼ | 34 | 38 | 30 | 33 | 24 | 27 | 17 | 19 | 45 | 51 | 39 | 44 | 32 | 36 | 23 | 26 |

GENERAL NOTES:

HT = hand-tucked splice.

MS = mechanical splice.

Rated loads based on minimum D/d ratio of 25/1.

Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

| Hitch Type | Single-Leg | Two-Leg Bridle or Basket | Choker | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|||||||||||||||||

| Vertical | Choker | Vertical Basket | Horizontal Angle | Horizontal Angle | |||||||||||||||||

| Vertical | 60° | 45° | 30° | 60° | 30° | ||||||||||||||||

| Rope Diameter, in. | HT | MS | S | HT | MS | HT | MS | S | HT | MS | S | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS |

| ¼ | 0.54 | 0.65 | 0.68 | 0.42 | 0.48 | 1.1 | 1.3 | 1.3 | 1.1 | 1.3 | 1.3 | 0.94 | 1.1 | 0.77 | 0.91 | 0.54 | 0.65 | 0.73 | 0.82 | 0.42 | 0.48 |

| 5/16 | 0.83 | 1.0 | 1.1 | 0.66 | 0.74 | 1.7 | 2.0 | 1.9 | 1.7 | 2.0 | 1.9 | 1.4 | 1.7 | 1.2 | 1.4 | 0.83 | 1.0 | 1.1 | 1.3 | 0.66 | 0.74 |

| ⅜ | 1.2 | 1.4 | 1.5 | 0.94 | 1.1 | 2.4 | 2.9 | 2.8 | 2.4 | 2.9 | 2.8 | 2.0 | 2.5 | 1.7 | 2.0 | 1.2 | 1.4 | 1.6 | 1.8 | 0.94 | 1.1 |

| 7/16 | 1.6 | 1.9 | 2.0 | 1.3 | 1.4 | 3.2 | 3.9 | 3.8 | 3.2 | 3.9 | 3.8 | 2.7 | 3.4 | 2.2 | 2.7 | 1.6 | 1.9 | 2.2 | 2.5 | 1.3 | 1.4 |

| ½ | 2.0 | 2.5 | 2.7 | 1.6 | 1.9 | 4.0 | 5.1 | 4.9 | 4.0 | 5.1 | 4.98 | 3.5 | 4.4 | 2.9 | 3.6 | 2.0 | 2.5 | 2.9 | 3.2 | 1.6 | 1.9 |

| 9/16 | 2.5 | 3.2 | 3.4 | 2.1 | 2.4 | 5.0 | 6.4 | 6.2 | 5.0 | 6.4 | 6.2 | 4.4 | 5.5 | 3.6 | 4.5 | 2.5 | 3.2 | 3.6 | 4.1 | 2.1 | 2.4 |

| ⅝ | 3.1 | 3.9 | 4.1 | 2.6 | 2.9 | 6.2 | 7.8 | 7.6 | 6.2 | 7.8 | 7.6 | 5.3 | 6.8 | 4.4 | 5.5 | 3.1 | 3.9 | 4.5 | 5.0 | 2.6 | 2.9 |

| ¾ | 4.3 | 5.6 | 5.9 | 3.7 | 4.1 | 8.6 | 11 | 11 | 8.6 | 11 | 11 | 7.4 | 9.7 | 6.1 | 7.9 | 4.3 | 5.6 | 6.3 | 7.1 | 3.7 | 4.1 |

| ¾ | 5.7 | 7.6 | 8.0 | 5.0 | 5.6 | 11 | 15 | 15 | 11 | 15 | 15 | 9.8 | 13 | 8.0 | 11 | 5.7 | 7.6 | 8.6 | 9.7 | 5.0 | 5.6 |

| 1 | 7.4 | 9.8 | 10 | 6.4 | 7.2 | 15 | 20 | 19 | 15 | 20 | 19 | 13 | 17 | 10 | 14 | 7.4 | 9.8 | 11 | 13 | 6.4 | 7.2 |

| 1 ⅛ | 9.3 | 12 | 13 | 8.1 | 9.1 | 19 | 24 | 24 | 19 | 24 | 24 | 16 | 21 | 13 | 17 | 9.3 | 12 | 14 | 16 | 8.1 | 9.1 |

| 1 ¼ | 11 | 15 | 16 | 9.9 | 11 | 23 | 30 | 30 | 23 | 30 | 30 | 20 | 26 | 16 | 21 | 11 | 15 | 17 | 19 | 9.9 | 11 |

| 1 ⅜ | 14 | 18 | 19 | 12 | 13 | 27 | 36 | 36 | 27 | 36 | 36 | 24 | 31 | 19 | 25 | 14 | 18 | 21 | 23 | 12 | 13 |

| 1 ½ | 16 | 21 | 23 | 14 | 16 | 32 | 42 | 42 | 32 | 42 | 42 | 28 | 37 | 23 | 30 | 16 | 21 | 25 | 28 | 14 | 16 |

| 1 ⅝ | 19 | 24 | 26 | 16 | 18 | 38 | 49 | 49 | 38 | 49 | 49 | 33 | 42 | 27 | 35 | 19 | 24 | 29 | 32 | 16 | 18 |

| 1 ¾ | 22 | 28 | 31 | 19 | 21 | 44 | 57 | 57 | 44 | 57 | 57 | 38 | 49 | 31 | 40 | 22 | 28 | 33 | 37 | 19 | 21 |

| 1 ⅞ | 25 | 32 | 35 | 22 | 24 | 50 | 64 | 64 | 50 | 64 | 64 | 43 | 56 | 35 | 46 | 25 | 32 | 38 | 42 | 22 | 24 |

| 2 | 28 | 37 | 40 | 25 | 28 | 56 | 73 | 73 | 56 | 73 | 73 | 49 | 63 | 40 | 52 | 28 | 37 | 43 | 48 | 25 | 28 |

GENERAL NOTES:

HT = hand-tucked splice.

MS = mechanical splice.

S = swaged or poured socket.

Rated loads based on minimum D/d ratio of 25/1.

(e) Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(f) For choker hitch, the angle of choke is 120 deg or greater.

| Three-Leg | Four-Leg | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||||||||

| Horizontal Angle | Horizontal Angle | |||||||||||||||

| Vertical | 60 deg | 45 deg | 30 deg | Vertical | 60 deg | 45 deg | 30 deg | |||||||||

| Rope Diameter, in. | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS |

| ¼ | 1.6 | 1.9 | 1.4 | 1.7 | 1.2 | 1.4 | 0.81 | 0.97 | 2.2 | 2.6 | 1.9 | 2.2 | 1.5 | 1.8 | 1.1 | 1.3 |

| 5/16 | 2.5 | 3.0 | 2.2 | 2.6 | 1.8 | 2.1 | 1.3 | 1.5 | 3.3 | 4.0 | 2.9 | 3.5 | 2.4 | 2.8 | 1.7 | 2.0 |

| ⅜ | 3.5 | 4.3 | 3.1 | 3.7 | 2.5 | 3.0 | 1.8 | 2.2 | 4.7 | 5.7 | 4.1 | 5.0 | 3.3 | 4.1 | 2.4 | 2.9 |

| 7/16 | 4.7 | 5.8 | 4.1 | 5.0 | 3.4 | 4.1 | 2.4 | 2.9 | 6.3 | 7.8 | 5.5 | 6.7 | 4.5 | 5.5 | 3.2 | 3.9 |

| ½ | 6.1 | 7.6 | 5.3 | 6.6 | 4.3 | 5.4 | 3.0 | 3.8 | 8.1 | 10 | 7.0 | 8.8 | 5.7 | 7.1 | 4.0 | 5.1 |

| 9/16 | 7.6 | 9.6 | 6.6 | 8.3 | 5.4 | 6.8 | 3.8 | 4.8 | 10 | 13 | 8.7 | 11 | 7.1 | 9.0 | 5.0 | 6.4 |

| ⅝ | 9.3 | 12 | 8.0 | 10 | 6.5 | 8.3 | 4.6 | 5.9 | 12 | 16 | 11 | 14 | 8.7 | 11 | 6.2 | 7.8 |

| ¾ | 13 | 17 | 11 | 15 | 9.1 | 12 | 6.4 | 8.4 | 17 | 22 | 15 | 19 | 12 | 16 | 8.6 | 11 |

| ⅞ | 17 | 23 | 15 | 20 | 12 | 16 | 8.5 | 11 | 23 | 30 | 20 | 26 | 16 | 21 | 11 | 15 |

| 1 | 22 | 29 | 19 | 26 | 16 | 21 | 11 | 15 | 29 | 39 | 25 | 34 | 21 | 28 | 15 | 20 |

| 1 ⅛ | 28 | 36 | 24 | 31 | 20 | 26 | 14 | 18 | 37 | 48 | 32 | 42 | 26 | 34 | 19 | 24 |

| 1 ¼ | 34 | 44 | 30 | 38 | 24 | 31 | 17 | 22 | 45 | 59 | 39 | 51 | 32 | 42 | 23 | 30 |

| 1 ⅜ | 41 | 53 | 36 | 46 | 29 | 38 | 21 | 27 | 55 | 71 | 47 | 62 | 39 | 50 | 27 | 36 |

| 1 ½ | 49 | 63 | 42 | 55 | 34 | 45 | 24 | 32 | 65 | 84 | 56 | 73 | 46 | 60 | 32 | 42 |

| 1 ⅝ | 56 | 73 | 49 | 63 | 40 | 52 | 28 | 37 | 75 | 98 | 65 | 85 | 53 | 69 | 38 | 49 |

| 1 ¾ | 65 | 85 | 57 | 74 | 46 | 60 | 33 | 42 | 87 | 113 | 76 | 98 | 62 | 80 | 44 | 57 |

| 1 ⅞ | 74 | 97 | 64 | 84 | 53 | 68 | 37 | 48 | 99 | 129 | 86 | 112 | 70 | 91 | 50 | 64 |

| 2 | 84 | 110 | 73 | 95 | 60 | 78 | 42 | 55 | 113 | 147 | 98 | 127 | 80 | 104 | 56 | 73 |

GENERAL NOTES:

HT = hand-ticked splice.

MS = mechanical splice

Rated loads based on minimum D/d ratio of 25/1.

Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

| Hitch Type | Single-Leg | Two-Leg Bridle | Choker | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

||||||||||||||||

| Vertical | Choker | Vertical Basket | Vertical | 60° | 45° | 30° | 60° | 30° | ||||||||||||

| Rope Diameter, in. | HT | MS | S | HT | MS | HT | MS | S | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS |

| ¼ | 0.60 | 0.71 | 0.74 | 0.46 | 0.52 | 1.2 | 1.4 | 1.4 | 1.2 | 1.4 | 1.0 | 1.2 | 0.84 | 1.0 | 0.60 | 0.71 | 0.80 | 0.90 | 0.46 | 0.52 |

| 5/16 | 0.92 | 1.1 | 1.2 | 0.72 | 0.81 | 1.8 | 2.2 | 2.1 | 1.8 | 2.2 | 1.6 | 1.9 | 1.3 | 1.6 | 0.92 | 1.1 | 1.2 | 1.4 | 0.72 | 0.81 |

| ⅜ | 1.3 | 1.6 | 1.7 | 1.0 | 1.2 | 2.6 | 3.2 | 3.1 | 2.6 | 3.2 | 2.3 | 2.7 | 1.8 | 2.2 | 1.3 | 1.6 | 1.8 | 2.0 | 1.0 | 1.2 |

| 7/16 | 1.7 | 2.1 | 2.2 | 1.4 | 1.6 | 3.5 | 4.3 | 4.1 | 3.5 | 4.3 | 3.0 | 3.7 | 2.5 | 3.0 | 1.7 | 2.1 | 2.4 | 2.7 | 1.4 | 1.6 |

| ½ | 2.2 | 2.8 | 2.9 | 1.8 | 2.0 | 4.5 | 5.5 | 5.4 | 4.5 | 5.5 | 3.9 | 4.8 | 3.1 | 3.9 | 2.2 | 2.8 | 3.1 | 3.5 | 1.8 | 2.0 |

| 9/16 | 2.8 | 3.5 | 3.7 | 2.3 | 2.6 | 5.6 | 7.0 | 6.8 | 5.6 | 7.0 | 4.8 | 6.1 | 3.9 | 5.0 | 2.8 | 3.5 | 4.0 | 4.5 | 2.3 | 2.6 |

| ⅝ | 3.4 | 4.3 | 4.5 | 2.8 | 3.2 | 6.8 | 8.6 | 8.4 | 6.8 | 8.6 | 5.9 | 7.5 | 4.8 | 6.1 | 3.4 | 4.3 | 4.9 | 5.5 | 2.8 | 3.2 |

| ¾ | 4.7 | 6.2 | 6.5 | 4.0 | 4.5 | 9.4 | 12 | 12 | 9.4 | 12 | 8.2 | 11 | 6.7 | 8.7 | 4.7 | 6.2 | 7.0 | 7.9 | 4.0 | 4.5 |

| ⅞ | 6.2 | 8.3 | 8.8 | 5.5 | 6.1 | 12 | 17 | 16 | 12 | 17 | 11 | 14 | 8.8 | 12 | 6.2 | 8.3 | 9.4 | 11 | 5.5 | 6.1 |

| 1 | 8.1 | 11 | 11 | 7.1 | 8.0 | 16 | 22 | 21 | 16 | 22 | 14 | 19 | 11 | 15 | 8.1 | 11 | 12 | 14 | 7.1 | 8.0 |

| 1 ⅛ | 10 | ... | 14 | 8.9 | ... | 20 | ... | 26 | 26 | ... | 18 | ... | 14 | ... | 10 | ... | 15 | ... | 8.9 | ... |

| 1 ¼ | 13 | ... | 18 | 11 | ... | 25 | ... | 33 | 25 | ... | 22 | ... | 18 | ... | 13 | ... | 19 | ... | 11 | ... |

| 1 ⅜ | 15 | ... | 21 | 13 | ... | 30 | ... | 39 | 30 | ... | 26 | ... | 21 | ... | 15 | ... | 23 | ... | 13 | ... |

| 1 ½ | 18 | ... | 25 | 16 | ... | 36 | ... | 46 | 36 | ... | 31 | ... | 25 | ... | 18 | ... | 27 | ... | 16 | ... |

| 1 ⅝ | 21 | ... | 29 | 18 | ... | 41 | ... | 54 | 41 | ... | 36 | ... | 29 | ... | 21 | ... | 31 | ... | 18 | ... |

| 1 ¾ | 24 | ... | 34 | 21 | ... | 48 | ... | 63 | 48 | ... | 42 | ... | 34 | ... | 24 | ... | 36 | ... | 21 | ... |

| 1 ⅞ | 27 | ... | 38 | 24 | ... | 55 | ... | 71 | 55 | ... | 47 | ... | 39 | ... | 27 | ... | 41 | ... | 24 | ... |

| 2 | 31 | ... | 43 | 27 | ... | 62 | ... | 80 | 62 | ... | 54 | ... | 44 | ... | 31 | ... | 47 | ... | 27 | ... |

GENERAL NOTES:

HT = hand-tucked splice.

MS = mechanical splice.

S = swaged or poured socket.

Rated loads based on minimum D/d ratio of 25/1.

(e) Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(f) For choker hitch, the angle of choke is 120 deg or greater.

| Three-Leg | Four-Leg | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

||||||||||||||

| Horizontal Angle | Horizontal Angle | |||||||||||||||

| Vertical | 60 deg | 45 deg | 30 deg | Vertical | 60 deg | 45 deg | 30 deg | |||||||||

| Rope Diameter, in. | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS | HT | MS |

| ¼ | 1.8 | 2.1 | 1.6 | 1.8 | 1.3 | 1.5 | 0.90 | 1.1 | 2.4 | 2.8 | 2.1 | 2.4 | 1.7 | 2.0 | 1.2 | 1.4 |

| 5/16 | 2.8 | 3.3 | 2.4 | 2.9 | 1.9 | 2.3 | 1.4 | 1.7 | 3.7 | 4.4 | 3.2 | 3.8 | 2.6 | 3.1 | 1.8 | 2.2 |

| ⅜ | 3.9 | 4.7 | 3.4 | 4.1 | 2.8 | 3.3 | 1.9 | 2.4 | 5.2 | 6.3 | 4.5 | 5.5 | 3.7 | 4.5 | 2.6 | 3.2 |

| 7/16 | 5.2 | 6.4 | 4.5 | 5.5 | 3.7 | 4.5 | 2.6 | 3.2 | 7.0 | 8.5 | 6.0 | 7.4 | 4.9 | 6.0 | 3.5 | 4.3 |

| ½ | 6.7 | 8.3 | 5.8 | 7.2 | 4.7 | 5.9 | 3.3 | 4.2 | 8.9 | 11 | 7.7 | 9.6 | 6.3 | 7.8 | 4.5 | 5.5 |

| 9/16 | 8.3 | 11 | 7.2 | 9.1 | 5.9 | 7.5 | 4.2 | 5.3 | 11 | 14 | 9.6 | 12 | 7.9 | 9.9 | 5.6 | 7.0 |

| ⅝ | 10 | 13 | 8.8 | 11 | 7.2 | 9.1 | 5.1 | 6.5 | 14 | 17 | 12 | 15 | 9.6 | 12 | 6.8 | 8.6 |

| ¾ | 14 | 18 | 12 | 16 | 10 | 13 | 7.1 | 9.2 | 19 | 25 | 16 | 21 | 13 | 17 | 9.4 | 12 |

| ⅞ | 19 | 25 | 16 | 22 | 13 | 18 | 9.4 | 12 | 25 | 33 | 22 | 29 | 18 | 24 | 12 | 17 |

| 1 | 24 | 32 | 21 | 28 | 17 | 23 | 12 | 16 | 32 | 43 | 28 | 37 | 23 | 31 | 16 | 22 |

| 1 ⅛ | 31 | ... | 26 | ... | 22 | ... | 15 | ... | 41 | ... | 35 | ... | 29 | ... | 20 | ... |

| 1 ¼ | 38 | ... | 32 | ... | 27 | ... | 19 | ... | 50 | ... | 43 | ... | 35 | ... | 25 | ... |

| 1 ⅜ | 45 | ... | 39 | ... | 32 | ... | 23 | ... | 60 | ... | 52 | ... | 43 | ... | 30 | ... |

| 1 ½ | 53 | ... | 46 | ... | 38 | ... | 27 | ... | 71 | ... | 62 | ... | 50 | ... | 36 | ... |

| 1 ⅝ | 62 | ... | 54 | ... | 44 | ... | 31 | ... | 83 | ... | 72 | ... | 59 | ... | 41 | ... |

| 1 ¾ | 72 | ... | 62 | ... | 51 | ... | 36 | ... | 96 | ... | 83 | ... | 68 | ... | 48 | ... |

| 1 ⅞ | 82 | ... | 71 | ... | 58 | ... | 41 | ... | 109 | ... | 95 | ... | 77 | ... | 55 | ... |

| 2 | 93 | ... | 80 | ... | 66 | ... | 46 | ... | 124 | ... | 107 | ... | 88 | ... | 62 | ... |

GENERAL NOTES:

HT = hand-tucked splice.

MS = mechanical splice

Rated loads based on minimum D/d ratio of 25/1.

Rated load based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

| Single-Leg | Two-Leg Bridle | Two-Leg Choker | |||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|||||

| Hitch Type | Horizontal Angle | Horizontal Angle | |||||||

| Rope Diameter, in. |

Vertical | Choker | Vertical Basket |

Vertical | 60° | 45° | 30° | 60° | 30° |

| 7X7X7 Construction | |||||||||

| ¼ | 0.50 | 0.35 | 1.0 | 1.0 | 0.87 | 0.71 | 0.50 | 0.61 | 0.35 |

| ⅜ | 1.1 | 0.8 | 2.2 | 2.2 | 1.9 | 1.5 | 1.1 | 1.3 | 0.76 |

| ½ | 1.9 | 1.3 | 3.7 | 3.7 | 3.2 | 2.6 | 1.9 | 2.2 | 1.3 |

| ⅝ | 2.8 | 1.9 | 5.5 | 5.5 | 4.8 | 3.9 | 2.8 | 3.4 | 1.9 |

| ¾ | 3.8 | 2.7 | 7.6 | 7.6 | 6.6 | 5.4 | 3.8 | 4.6 | 2.7 |

| ⅞ | 5.0 | 3.5 | 10 | 10 | 8.7 | 7.1 | 5.0 | 6.1 | 3.5 |

| 1 | 6.4 | 4.5 | 13 | 13 | 11 | 9.1 | 6.4 | 7.8 | 4.5 |

| 7X7X19 Construction | |||||||||

| ½ | 1.9 | 1.3 | 3.8 | 3.8 | 3.3 | 2.7 | 1.9 | 2.3 | 1.3 |

| ⅝ | 2.9 | 2.0 | 5.8 | 5.8 | 5.0 | 4.1 | 2.9 | 3.5 | 2.0 |

| ¾ | 4.1 | 2.8 | 8.1 | 8.1 | 7.0 | 5.8 | 4.1 | 4.9 | 2.8 |

| ⅞ | 5.4 | 3.8 | 11 | 11 | 9.3 | 7.6 | 5.4 | 6.5 | 3.8 |

| 1 | 6.0 | 4.8 | 14 | 14 | 12 | 9.7 | 6.9 | 8.3 | 4.8 |

| 1 ⅛ | 8.3 | 5.8 | 17 | 17 | 14 | 12 | 8.3 | 10 | 5.8 |

| 1 ¼ | 9.9 | 6.9 | 20 | 20 | 17 | 14 | 9.9 | 12 | 6.9 |

| 7X6X19 or 7X6X36 IWRC Classification | |||||||||

| ¾ | 3.8 | 2.7 | 7.6 | 7.6 | 6.6 | 5.4 | 3.8 | 4.6 | 2.7 |

| ⅞ | 5.0 | 3.5 | 10 | 10 | 8.7 | 7.1 | 5.0 | 6.1 | 3.5 |

| 1 | 6.4 | 4.5 | 13 | 13 | 11 | 9.1 | 6.4 | 7.8 | 4.5 |

| 1 ⅛ | 7.7 | 5.4 | 15 | 15 | 13 | 11 | 7.7 | 9.3 | 5.4 |

| 1 ¼ | 9.3 | 6.5 | 19 | 19 | 16 | 13 | 9.3 | 11 | 6.5 |

| 1 ⅜ | 11 | 7.6 | 22 | 22 | 19 | 15 | 11 | 13 | 7.6 |

| 1 ½ | 13 | 9.0 | 26 | 26 | 22 | 18 | 13 | 16 | 9.0 |

| 1 ⅝ | 15 | 10 | 30 | 30 | 26 | 21 | 15 | 18 | 10 |

GENERAL NOTES:

(a) 7X7X7 = galvanized specialty cable.

(b) 7X7X19 = galvanized specialty cable.

(c) Rated loads based on minimum D/d ratio of 10/1.

(d) Rated loads based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(e) For choker hitch, the angle of choke is 120 deg or greater.

| Single-Leg | Two-Leg Bridle | Two-Leg Choker | |||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|||||

| Hitch Type | Horizontal Angle | Horizontal Angle | |||||||

| Vertical | Choker | Vertical Basket |

Vertical | 60° | 45° | 30° | 60° | 30° | |

| Rope Diameter, in. | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS |

| 3/16 | 1.6 | 1.4 | 3.2 | 3.2 | 2.8 | 2.3 | 1.6 | 2.4 | 1.4 |

| ¼ | 2.9 | 2.5 | 5.7 | 5.7 | 4.9 | 4.0 | 2.9 | 4.3 | 2.5 |

| 5/16 | 4.4 | 3.9 | 8.9 | 8.9 | 7.7 | 6.3 | 4.4 | 6.7 | 3.9 |

| ⅜ | 6.3 | 5.5 | 13 | 13 | 11 | 9.0 | 6.3 | 9.6 | 5.5 |

| 7/16 | 8.6 | 7.5 | 17 | 17 | 15 | 12 | 8.6 | 13 | 7.5 |

| ½ | 11 | 9.8 | 22 | 22 | 19 | 16 | 11 | 17 | 9.8 |

| 9/16 | 14 | 12 | 28 | 28 | 24 | 20 | 14 | 21 | 12 |

| ⅝ | 17 | 15 | 35 | 35 | 30 | 24 | 17 | 26 | 15 |

| ¾ | 25 | 22 | 49 | 49 | 43 | 35 | 25 | 37 | 22 |

| ⅞ | 33 | 29 | 67 | 67 | 58 | 47 | 33 | 51 | 29 |

| 1 | 43 | 38 | 87 | 87 | 75 | 61 | 43 | 66 | 38 |

| 1 ⅛ | 55 | 48 | 109 | 109 | 95 | 77 | 55 | 83 | 48 |

| 1 ¼ | 67 | 59 | 134 | 134 | 116 | 95 | 67 | 102 | 59 |

| 1 ⅜ | 87 | 71 | 161 | 161 | 140 | 114 | 81 | 122 | 71 |

| 1 ½ | 96 | 84 | 192 | 192 | 166 | 135 | 96 | 145 | 84 |

| 1 ⅝ | 111 | 97 | 222 | 222 | 192 | 157 | 111 | 168 | 97 |

| 1 ¾ | 129 | 112 | 257 | 257 | 223 | 182 | 129 | 195 | 112 |

| 1 ⅞ | 146 | 128 | 292 | 292 | 253 | 207 | 146 | 222 | 128 |

| 2 | 166 | 146 | 333 | 333 | 288 | 235 | 166 | 252 | 146 |

GENERAL NOTES:

(a) HT = hand-tucked splice.

(b) MT = mechanical splice.

(c) Rated loads based on minimum D/d ratio of 25 times the component rope diameter.

(d) Rated loads based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(e) For choker hitch, the angle of choke is 120 deg or greater.

| Single-Leg | Two-Leg Bridle | Two-Leg Choker | |||||||

|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|||||

| Hitch Type | Horizontal Angle | Horizontal Angle | |||||||

| Vertical | Choker | Vertical Basket |

Vertical | 60° | 45° | 30° | 60° | 30° | |

| Rope Diameter, in. | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS | HT&MS |

| 3/16 | 2.2 | 1.9 | 4.3 | 4.3 | 3.7 | 3.0 | 2.2 | 3.3 | 1.9 |

| ¼ | 3.8 | 3.3 | 7.6 | 7.6 | 6.6 | 5.4 | 3.8 | 5.8 | 3.3 |

| 5/16 | 5.9 | 5.2 | 12 | 12 | 10 | 8.3 | 5.9 | 8.9 | 5.2 |

| ⅜ | 8.5 | 7.4 | 17 | 17 | 15 | 12 | 8.5 | 13 | 7.4 |

| 7/16 | 11 | 10 | 23 | 23 | 20 | 16 | 11 | 17 | 10 |

| ½ | 15 | 13 | 30 | 30 | 26 | 21 | 15 | 23 | 13 |

| 9/16 | 19 | 16 | 38 | 38 | 33 | 27 | 19 | 29 | 16 |

| ¾ | 23 | 20 | 46 | 46 | 40 | 33 | 23 | 35 | 20 |

| ¾ | 33 | 29 | 66 | 66 | 57 | 47 | 33 | 50 | 29 |

| ⅞ | 45 | 39 | 89 | 89 | 77 | 63 | 45 | 68 | 39 |

| 1 | 58 | 51 | 116 | 116 | 100 | 82 | 58 | 88 | 51 |

| 1 ⅛ | 73 | 64 | 146 | 146 | 126 | 103 | 73 | 110 | 64 |

| 1 ¼ | 89 | 78 | 179 | 179 | 155 | 127 | 89 | 136 | 78 |

| 1 ⅜ | 108 | 94 | 215 | 215 | 186 | 152 | 108 | 163 | 94 |

| 1 ½ | 128 | 112 | 255 | 255 | 221 | 181 | 128 | 194 | 112 |

| 1 ⅝ | 148 | 129 | 296 | 296 | 256 | 209 | 148 | 224 | 129 |

| 1 ¾ | 171 | 150 | 343 | 343 | 297 | 242 | 171 | 260 | 150 |

| 1 ⅞ | 195 | 171 | 390 | 390 | 338 | 276 | 195 | 295 | 171 |

| 2 | 222 | 194 | 444 | 444 | 384 | 314 | 222 | 336 | 194 |

GENERAL NOTES:

(a) HT = hand-tucked splice.

(b) MT = mechanical splice.

(c) Rated loads based on minimum D/d ratio of 25 times the component rope diameter.

(d) Rated loads based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

(e) For choker hitch, the angle of choke is 120 deg or greater.

| Heavy Duty | Medium Duty | Light Duty | |

|---|---|---|---|

| Nominal spiral turns per foot mesh width | 35 | 43 | 59 |

| Approx. spiral wire size | 10 gage | 12 gage | 14 gage |

| Equivalent decimal size | 0.135 in. | 0.105 in. | 0.080 in. |

| Nominal cross rods per foot of fabric length | 21 | 30 | 38 |

| Approx. size of cross rods | 8 gage | 10 gage | 14 gage |

| Equivalent decimal size | 0.162 in. | 0.135 in. | 0.080 in. |

| Nominal fabric thickness | 1/2 in. | 3/8 in. | 5/16 in. |

| Effect of Angle on Rated Capacities in Basket Hitch | |||||

|---|---|---|---|---|---|

|

|

|

|

||

| Hitch Type | Vertical or Choker | Vertical Basket | 60° | 45° | 30° |

| Width, in. | |||||

| Heavy Duty - 10 gage [Rated Loads in Pounds (lb)] | |||||

| 2 | 1,600 | 3,200 | 2,770 | 2,260 | 1,600 |

| 3 | 3,000 | 6,000 | 5,200 | 4,240 | 3,000 |

| 4 | 4,400 | 8,800 | 7,620 | 6,220 | 4,400 |

| 6 | 6,600 | 13,200 | 11,430 | 9,330 | 6,600 |

| 8 | 8,800 | 17,600 | 15.240 | 12,440 | 8,800 |

| 10 | 11,000 | 22,000 | 19,050 | 15,550 | 11,000 |

| 12 | 13,200 | 26,400 | 22.860 | 18,660 | 13,200 |

| 14 | 15,400 | 30,800 | 26,670 | 21,770 | 15,400 |

| 16 | 17,600 | 35,200 | 30,480 | 24,880 | 17,600 |

| 18 | 19,800 | 39,600 | 34.290 | 28,000 | 19,800 |

| 20 | 22,000 | 44,000 | 38,100 | 31,100 | 22,000 |

| Medium Duty - 12 gage [Rated Loads in Pounds (lb)] | |||||

| 2 | 1,450 | 2,900 | 2,510 | 2,050 | 1,450 |

| 3 | 2,170 | 4,350 | 3,770 | 3,070 | 2,170 |

| 4 | 2,900 | 5,800 | 5,020 | 4,100 | 2,900 |

| 6 | 4,800 | 9,600 | 8,310 | 6,780 | 4,800 |

| 8 | 6,400 | 12,800 | 11,080 | 9,050 | 6,400 |

| 10 | 8,000 | 16,000 | 13,850 | 11,310 | 8,000 |

| 12 | 9,600 | 19,200 | 16,620 | 13,570 | 9,600 |

| 14 | 11,200 | 22,400 | 19,400 | 15,830 | 11,200 |

| 16 | 12,800 | 25,600 | 22,170 | 18,100 | 12,800 |

| 18 | 13,500 | 27,000 | 23.380 | 19,090 | 13,500 |

| 20 | 15,000 | 30,000 | 25,980 | 21,210 | 15,000 |

| Light Duty - 14 gage [Rated Loads in Pounds (lb)] | |||||

| 2 | 900 | 1,800 | 1,560 | 1,270 | 900 |

| 3 | 1,400 | 2,800 | 2,420 | 1,980 | 1,400 |

| 4 | 2,000 | 4,800 | 4,150 | 3,390 | 2,000 |

| 6 | 3,000 | 6,000 | 5,190 | 4,240 | 3,000 |

| 8 | 4,000 | 8,000 | 6,920 | 5,650 | 4,000 |

| 10 | 5,000 | 10,000 | 8,660 | 7,070 | 5,000 |

| 12 | 6,000 | 12,000 | 10,390 | 8,480 | 6,000 |

| 14 | 7,000 | 14,000 | 12,120 | 9,890 | 7,000 |

| 16 | 8,000 | 16,000 | 13,850 | 11,310 | 8,000 |

| 18 | 9,000 | 18,000 | 15,580 | 12,720 | 9,000 |

| 20 | 10,000 | 20,000 | 17,320 | 14,140 | 10,000 |

GENERAL NOTE: For choker hitch, the angle of choke is 120 deg or greater.

| Eye-and-Eye Sling - Hitch Type | Endless Sling - Hitch Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

||||||

| Two-Leg Bridle or Basket | Basket | |||||||||||

| Horizontal Angle, deg | Horizontal Angle, deg | |||||||||||

| Rope Diameter, in. | Vertical | Choker | 90° | 60° | 45° | 30° | Vertical | Choker | 90° | 60° | 45° | 30° |

| 1/2 | 1,100 | 830 | 2,200 | 1,900 | 1,600 | 1,100 | 2,000 | 1,500 | 4,000 | 3,500 | 2,800 | 2,000 |

| 9/16 | 1,400 | 1,100 | 2,800 | 2,400 | 2,000 | 1,400 | 2,600 | 2,000 | 5,200 | 4,500 | 3,700 | 2,600 |

| ⅝ | 1,800 | 1,400 | 3,600 | 3,100 | 2,500 | 1,800 | 3,200 | 2,400 | 6,400 | 5,500 | 4,500 | 3,200 |

| ¾ | 2,600 | 2,000 | 5,200 | 4,500 | 3,700 | 2,600 | 4,600 | 3,500 | 9,200 | 8,000 | 6,500 | 4,600 |

| ⅞ | 3,500 | 2,600 | 7,000 | 6,100 | 4,900 | 3,500 | 6,200 | 4,700 | 12,400 | 10,700 | 8,800 | 6,200 |

| 1 | 4,400 | 3,300 | 8,800 | 7,600 | 6,200 | 4,400 | 7,900 | 5,900 | 15,800 | 13,700 | 11,200 | 7,900 |

| 1 ⅛ | 5,700 | 4,300 | 11,400 | 9,900 | 8,100 | 5,700 | 10,100 | 7,600 | 20,200 | 17,500 | 14,300 | 10,100 |

| 1 ¼ | 7,000 | 5,300 | 14,000 | 12,100 | 9,900 | 7,000 | 12,400 | 9,300 | 24,800 | 21,500 | 17,500 | 12,400 |

| 1 5/16 | 7,700 | 5,800 | 15,400 | 13,300 | 10,900 | 7,700 | 13,700 | 10,300 | 27,400 | 23,700 | 19,400 | 13,700 |

| 1 ½ | 9,700 | 7,300 | 19,400 | 16,800 | 13,700 | 9,700 | 17,400 | 13,100 | 34,800 | 30,100 | 24,600 | 17,400 |

| 1 ⅞ | 11,500 | 8,600 | 23,000 | 19,900 | 16,300 | 11,500 | 20,500 | 15,400 | 41,000 | 35,500 | 29,000 | 20,500 |

| 1 ⅞ | 13,200 | 9,900 | 26,400 | 22,900 | 18,700 | 13,200 | 23,600 | 17,700 | 47,200 | 40,900 | 33,400 | 23,600 |

| 2 | 16,900 | 12,700 | 33,800 | 29,300 | 23,900 | 16,900 | 30,200 | 22,700 | 60,400 | 52,300 | 42,700 | 30,200 |

| 2 ⅛ | 19,100 | 14,300 | 38,200 | 33,100 | 27,000 | 19,100 | 34,100 | 25,600 | 68,200 | 59,100 | 48,200 | 34,100 |

| 2 ¼ | 21,400 | 16,100 | 42,800 | 37,100 | 30,300 | 21,400 | 38,300 | 28,700 | 76,600 | 66,300 | 54,200 | 38,300 |

| 2 ½ | 26,300 | 19,700 | 52,600 | 45,600 | 37,200 | 26,300 | 46,900 | 35,200 | 93,800 | 81,200 | 66,300 | 46,900 |

| 2 ⅝ | 28,800 | 21,600 | 57,600 | 49,900 | 40,700 | 28,800 | 51,400 | 38,600 | 102,800 | 89,000 | 72,700 | 51,400 |

| 3 | 37,100 | 27,800 | 74,200 | 64,300 | 52,500 | 37,100 | 66,200 | 49,700 | 132,400 | 114,700 | 93,600 | 66,200 |

GENERAL NOTES:

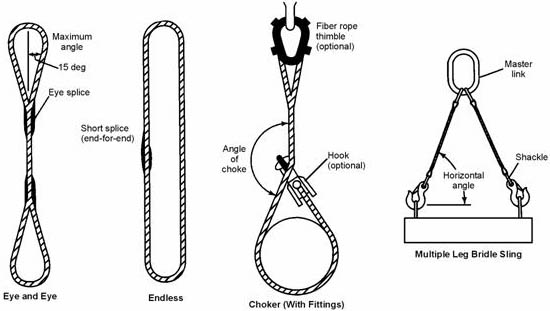

(a) See Fig. 8 for sling types, Fig. 5 for hitch types, and Fig. 3 for sling angle descriptions. For D/d considerations see note in Fig. 5.

(b) For choker hitch, the angle of choke is 120 deg or greater.

| Eye-and-Eye Sling - Hitch Type | Endless Sling - Hitch Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

||||||

| Two-Leg Bridle or Basket | Basket | |||||||||||

| Horizontal Angle, deg | Horizontal Angle, deg | |||||||||||

| Rope Diameter, in. | Vertical | Choker | 90° | 60° | 45° | 30° | Vertical | Choker | 90° | 60° | 45° | 30° |

| ½ | 1,000 | 750 | 2,000 | 1,700 | 1,400 | 1,000 | 1,800 | 1,400 | 3,600 | 3,100 | 2,500 | 1,800 |

| 9/16 | 1,300 | 980 | 2,600 | 2,300 | 1,800 | 1,300 | 2,300 | 1,700 | 4,600 | 4,000 | 3,300 | 2,300 |

| ⅝ | 1,600 | 1,200 | 3,200 | 2,800 | 2,300 | 1,600 | 2,800 | 2,100 | 5,600 | 4,800 | 4,000 | 2,800 |

| ¾ | 2,200 | 1,700 | 4,400 | 3,800 | 3,100 | 2,200 | 4,000 | 3,000 | 8,000 | 6,900 | 5,700 | 4,000 |

| ⅞ | 3,000 | 2,300 | 6,000 | 5,200 | 4,200 | 3.000 | 5,400 | 4,100 | 10,800 | 9,400 | 7,600 | 5,400 |

| 1 | 4,000 | 3,000 | 8,000 | 6,900 | 5,700 | 4,000 | 7,100 | 5,300 | 14,200 | 12,300 | 10,000 | 7,100 |

| 1 ⅛ | 5,000 | 3,800 | 10,000 | 8,700 | 7,100 | 5,000 | 8,900 | 6,700 | 17,800 | 15,400 | 12,600 | 8,900 |

| 1 ¼ | 6,000 | 4,500 | 12,000 | 10,400 | 8,500 | 6,000 | 10,600 | 8,000 | 21,200 | 18,400 | 15,000 | 10,600 |

| 1 5/16 | 6,500 | 4,900 | 13,000 | 11,300 | 9,200 | 6,500 | 11,600 | 8,700 | 23,200 | 20,100 | 16,400 | 11,600 |

| 1 ½ | 8,400 | 6,300 | 16,800 | 14,500 | 11,900 | 8,400 | 15,100 | 11,300 | 30,200 | 26,200 | 21,400 | 15,100 |

| 1 ⅝ | 9,900 | 7,400 | 19,800 | 17,100 | 14,000 | 9,900 | 17,600 | 13,200 | 35,200 | 30,500 | 24,900 | 17,600 |

| 1 ⅞ | 11,400 | 8,600 | 22,800 | 19,700 | 16,100 | 11,400 | 20,400 | 15,300 | 40,800 | 35,300 | 28,800 | 20,400 |

| 2 | 14,400 | 10,800 | 28,800 | 24,900 | 20,400 | 14,400 | 25,700 | 19,300 | 51,400 | 44,500 | 36,300 | 25,700 |

| 2 ⅛ | 16,200 | 12,200 | 32,400 | 28,100 | 22,900 | 16,200 | 28,900 | 21,700 | 57,800 | 50,100 | 40,900 | 28,900 |

| 2 ¼ | 18,100 | 13,600 | 36,200 | 31,300 | 25,600 | 18,100 | 32,300 | 24,200 | 64,600 | 55,900 | 45,700 | 32,300 |

| 2 ½ | 22,000 | 16,500 | 44,000 | 38,100 | 31,100 | 22,000 | 39,300 | 29,500 | 78,600 | 68,100 | 55,600 | 39,300 |

| 2 ⅝ | 24,200 | 18,200 | 48,400 | 41,900 | 34,200 | 24,200 | 43,200 | 32,400 | 86,400 | 74,800 | 61,100 | 43,200 |

| 3 | 31,200 | 23,400 | 62,400 | 54,000 | 44,100 | 31,200 | 55,700 | 41,800 | 111.400 | 96,500 | 78,800 | 55,700 |

GENERAL NOTES:

(a) See Fig. 8 for sling types, Fig. 5 for hitch types, and Fig. 3 for sling angle descriptions. For D/d considerations see note in Fig. 5.

(b) For choker hitch, the angle of choke is 120 deg or greater.

| Eye-and-Eye Sling - Hitch Type | Endless Sling - Hitch Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

||||||

| Two-Leg Bridle or Basket | Basket | |||||||||||

| Horizontal Angle, deg | Horizontal Angle, deg | |||||||||||

| Rope Diameter, in. | Vertical | Choker | 90° | 60° | 45° | 30° | Vertical | Choker | 90° | 60° | 45° | 30° |

| ½ | 760 | 570 | 1,500 | 1,300 | 1,100 | 750 | 1,400 | 1,100 | 2,800 | 2,400 | 2,000 | 1,400 |

| 9/16 | 920 | 690 | 1,800 | 1,600 | 1,300 | 900 | 1,600 | 1,200 | 3,200 | 2,800 | 2,300 | 1,699 |

| ⅝ | 1,100 | 830 | 2,200 | 1,900 | 1,600 | 1,100 | 2,000 | 1,500 | 4,000 | 3,500 | 2,800 | 2,000 |

| ¾ | 1,500 | 1,100 | 3,000 | 2,600 | 2,100 | 1,500 | 2,700 | 2,000 | 5,400 | 4,700 | 3,800 | 2,700 |

| ⅞ | 2,100 | 1,600 | 4,200 | 3,600 | 3,000 | 2,100 | 3,700 | 2,800 | 7,400 | 6,400 | 5,200 | 3,700 |

| 1 | 2,600 | 2,000 | 5,200 | 4,500 | 3,700 | 2,600 | 4,600 | 3,500 | 9,200 | 8,000 | 6,500 | 4,600 |

| 1 ⅛ | 3,200 | 2,400 | 6,400 | 5,500 | 4,500 | 3,200 | 5,700 | 4,300 | 11,400 | 9,900 | 8,100 | 5,700 |

| 1 ¼ | 3,900 | 2,900 | 7,800 | 6,800 | 5,500 | 3,900 | 6,900 | 5,200 | 13,800 | 12,000 | 9,800 | 6,900 |

| 1 5/16 | 4,200 | 3,200 | 8,400 | 7,300 | 5,900 | 4,200 | 7,600 | 5,700 | 15,200 | 13,200 | 10,700 | 7,600 |

| 1 ½ | 5,500 | 4,100 | 11,000 | 9,500 | 7,800 | 5,500 | 9,800 | 7,400 | 19,600 | 17,000 | 13,900 | 9,800 |

| 1 ⅝ | 6,400 | 4,800 | 12,800 | 11,100 | 9,000 | 6,400 | 11,400 | 8,600 | 22,800 | 19,700 | 16,100 | 11,400 |

| 1 ¾ | 7,400 | 5,600 | 14,800 | 12,800 | 10,500 | 7,400 | 13,200 | 9,900 | 26,400 | 22,900 | 18,700 | 13,200 |

| 2 | 9,400 | 7,100 | 18,800 | 16,300 | 13,300 | 9,400 | 16,700 | 12,500 | 33,400 | 28,900 | 23,600 | 16,700 |

| 2 ⅛ | 10,500 | 7,900 | 21,000 | 18,200 | 14,800 | 10,500 | 18,800 | 14,100 | 37,600 | 32,600 | 26,600 | 18,800 |

| 2 ¼ | 11,900 | 8,900 | 23,800 | 20,600 | 16,800 | 11,900 | 21,200 | 15,900 | 42,400 | 36,700 | 30,000 | 21,200 |

| 2 ½ | 14,400 | 10,800 | 28,800 | 24,900 | 20,400 | 14,400 | 25,700 | 19,300 | 51,400 | 44,500 | 36,300 | 25,700 |

| 2 ⅝ | 16,100 | 12,100 | 32,200 | 27,900 | 22,800 | 16,100 | 28,800 | 21,600 | 57,600 | 49,900 | 40,700 | 28,800 |

| 3 | 20,500 | 15,400 | 41,000 | 35,500 | 29,000 | 20,500 | 36,600 | 27,500 | 73,200 | 63,400 | 51,800 | 36,600 |

GENERAL NOTES:

(a) See Fig. 8 for sling types, Fig. 5 for hitch types, and Fig. 3 for sling angle descriptions. For D/d considerations see note in Fig. 5.

(b) For choker hitch, the angle of choke is 120 deg or greater.

| Types I, II, III, and IV | Type V | |||||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|||||

| Single-Leg - Hitch Type | Two Leg - Horizontal Angles | |||||||

| Vertical | Choker | Vertical Basket | Vertical | 60° | 45° | 30° | Endless Vertical | |

| Width, in. | ||||||||

| 1 | 1,100 | 880 | 2,200 | 2,200 | 1,900 | 1,600 | 1,100 | 2,200 |

| 1 ½ | 1,600 | 1,280 | 3,200 | 3,200 | 2,800 | 2,300 | 1,600 | 3,200 |

| 1 ¾ | 1,900 | 1,520 | 3,800 | 3,800 | 3,300 | 2,700 | 1,900 | 3,800 |

| 2 | 2,200 | 1,760 | 4,400 | 4,400 | 3,800 | 3,100 | 2,200 | 4,400 |

| 3 | 3,300 | 2,640 | 6,600 | 6,600 | 5,700 | 4,700 | 3,300 | 6,600 |

| 4 | 4,400 | 3,520 | 8,800 | 8,800 | 7,600 | 6,200 | 4,400 | 8,800 |

| 5 | 5,500 | 4,400 | 11,000 | 11,000 | 9,500 | 7,800 | 5,500 | 11,000 |

| 6 | 6,600 | 5,280 | 13,200 | 13,200 | 11,400 | 9,300 | 6,600 | 13,200 |

GENERAL NOTES:

(a) The rated loads are based on stuffer weave construction webbing with a minimum certified tensile strength of 6,800 pounds per inch of width of the webbing.

(b) Rated loads for Types III and IV slings apply to both tapered and nontapered eye constructions. Rated loads for Type V slings are based on nontapered webbing.

(c) For Type VI slings, consult the manufacturer for rated loads.

(d) For choker hitch, the angle of choke is 120 deg or greater.

| Types I, II, III, and IV | Type V | |||||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|||||

| Single-Leg - Hitch Type | Two Leg - Horizontal Angles | |||||||

| Vertical | Choker | Vertical Basket | Vertical | 60° | 45° | 30° | Endless Vertical | |

| Width, in. | ||||||||

| 1 | 2,200 | 1,760 | 4,400 | 4,400 | 3,800 | 3,100 | 2,200 | 4,400 |

| 1 ½ | 3,300 | 2,640 | 6,600 | 6,600 | 5,700 | 4,700 | 3,300 | 6,600 |

| 1 ¾ | 3,800 | 3,040 | 7,600 | 7,600 | 6,600 | 5,400 | 3,800 | 7,600 |

| 2 | 4,400 | 3,520 | 8,800 | 8,800 | 7,600 | 6,200 | 4,400 | 8,800 |

| 3 | 6,600 | 5,280 | 13,200 | 13,200 | 11,400 | 9,300 | 6,600 | 13,200 |

| 4 | 8,200 | 6,560 | 16,400 | 16,400 | 14,200 | 11,600 | 8,200 | 16,400 |

| 5 | 10,200 | 8,160 | 20,400 | 20,400 | 17,700 | 14,400 | 10,200 | 20,400 |

| 6 | 12,300 | 9,840 | 24,600 | 24,600 | 21,300 | 17,400 | 12,300 | 24,600 |

GENERAL NOTES:

(a) The rated loads are based on stuffer weave construction webbing with a minimum certified tensile strength of 6,800 pounds per inch of width of the webbing.

(b) Rated loads for Types III and IV slings apply to both tapered and nontapered eye constructions. Rated loads for Type V slings are based on nontapered webbing.

(c) For Type VI slings, consult the manufacturer for rated loads.

(d) For choker hitch, the angle of choke is 120 deg or greater.

| Types I, II, III, and IV | Type V | |||||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|||||

| Single-Leg - Hitch Types | Two Leg - Horizontal Angles | |||||||

| Sling Width, in. |

Vertical | Choker | Vertical Basket | Vertical Basket. | 60° | 45° | 30° | Endless Vertical |

| 1 | 1,600 | 1,280 | 3,200 | 3,200 | 2,800 | 2,300 | 1,600 | 3,200 |

| 1 ½ | 2,300 | 1,840 | 4,600 | 4,600 | 4,000 | 3,300 | 2,300 | 4,600 |

| 1 ¾ | 2,700 | 2,160 | 5,400 | 5,400 | 4,700 | 3,800 | 2,700 | 5,400 |

| 2 | 3,100 | 2,480 | 6,200 | 6,200 | 5,400 | 4,400 | 3,100 | 6,200 |

| 3 | 4,700 | 3,760 | 9,400 | 9,400 | 8,100 | 6,600 | 4,700 | 9,400 |

| 4 | 6,200 | 4,960 | 12,400 | 12,400 | 10,700 | 8,800 | 6,200 | 12,400 |

| 5 | 7,800 | 6,240 | 15,600 | 15,600 | 13,500 | 11,000 | 7,800 | 15,600 |

| 6 | 9,300 | 7,440 | 18,600 | 18,600 | 16,100 | 13,200 | 9,300 | 18,600 |

| 8 | 11,750 | 9,440 | 21,150 | 23,600 | 18,300 | 15,000 | 11,750 | 21,150 |

| 10 | 14,700 | 11,760 | 26,450 | 29,400 | 22,900 | 18,700 | 14,700 | 26,450 |

| 12 | 17,650 | 14,120 | 31,750 | 35,200 | 31,750 | 22,400 | 17,650 | 31,750 |

GENERAL NOTES:

(a) The rated loads are based on stuffer weave construction webbing with a minimum certified tensile strength of 9,800 pounds per inch of width of the webbing.

(b) Rated loads for Types III and IV slings apply to both tapered and nontapered eye constructions. Rated loads for Type V slings are based on nontapered webbing.

(c) For Type VI slings, consult the manufacturer for rated loads.

(d) For choker hitch, the angle of choke is 120 deg or greater.

| Types I, II, III, and IV | Type V | |||||||

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|||||

| Single-Leg - Hitch Types | Two Leg - Horizontal Angles | |||||||

| Sling Width, in. |

Vertical | Choker | Vertical Basket | Vertical Basket. | 60° | 45° | 30° | Endless Vertical |

| 1 | 3,100 | 2,480 | 6,200 | 6,200 | 5,400 | 4,400 | 3,100 | 6,200 |

| 1 ½ | 4,700 | 3,760 | 9,400 | 9,400 | 8,100 | 6,600 | 4,700 | 9,400 |

| 1 ¾ | 5,400 | 4,320 | 10,800 | 10,800 | 9,400 | 7,600 | 5,400 | 10,800 |

| 2 | 6,200 | 4,960 | 12,400 | 12,400 | 10,700 | 8,800 | 6,200 | 12,400 |

| 3 | 8,800 | 7,040 | 17,600 | 17,600 | 15,200 | 12,400 | 8,800 | 17,600 |

| 4 | 11,000 | 8,800 | 22,000 | 22,000 | 19,100 | 15,600 | 11,000 | 22,000 |

| 5 | 13,700 | 10,960 | 27,400 | 27,400 | 23,700 | 19,400 | 13,700 | 27,400 |

| 6 | 16,500 | 13,200 | 33,000 | 33,000 | 28,600 | 23,000 | 16,500 | 33,000 |

| 8 | 22,750 | 18,200 | 42,350 | 45,400 | 36,700 | 29,900 | 22,750 | 42,350 |

| 10 | 28,400 | 22,720 | 52,900 | 56,800 | 45,800 | 37,400 | 28,400 | 52,900 |

| 12 | 34,100 | 27,280 | 63,500 | 68,200 | 55,000 | 44,900 | 34,100 | 63,500 |

GENERAL NOTES:

(a) The rated loads are based on stuffer weave construction webbing with a minimum certified tensile strength of 9,800 pounds per inch of width of the webbing.

(b) Rated loads for Types III and IV slings apply to both tapered and nontapered eye constructions. Rated loads for Type V slings are based on nontapered webbing.

(c) For Type VI slings, consult the manufacturer for rated loads.

(d) For choker hitch, the angle of choke is 120 deg or greater.

| Types I, II, III, and IV | |||||||

|---|---|---|---|---|---|---|---|

|

|

|

|

||||

| Single-Leg - Hitch Types | Two Leg - Horizontal Angles | ||||||

| Sling Width, in. |

Vertical | Choker | Vertical Basket | Vertical Basket. | 60° | 45° | 30° |

| 1 | 5,500 | 4,400 | 11,000 | 11,000 | 9,500 | 7,800 | 5,500 |

| 2 | 11,000 | 8,800 | 22,000 | 22,000 | 19,000 | 15,600 | 11,000 |

| 3 | 16,450 | 13,160 | 32,900 | 32,800 | 28,500 | 23,300 | 16,450 |

| 4 | 20,400 | 16,320 | 40,800 | 40,800 | 35,300 | 28,800 | 20,400 |

| 5 | 25,500 | 20,400 | 51,000 | 51,000 | 44,200 | 36,100 | 25,500 |

| 6 | 30,600 | 24,480 | 61,200 | 61,200 | 53,000 | 43,300 | 30,600 |

GENERAL NOTES:

(a) The rated loads are based on stuffer weave construction webbing with a minimum certified tensile strength of 9,800 pounds per inch of width of the webbing.

(b) Rated loads for Types III and IV slings apply to both tapered and nontapered eye constructions. Rated loads for Type V slings are based on nontapered webbing.

(c) For Type VI slings, consult the manufacturer for rated loads.

(d) For choker hitch, the angle of choke is 120 deg or greater.

| Size | Hitch Type | Horizontal Angle, deg | ||||

|---|---|---|---|---|---|---|

|

|

|

||||

| Vertical | Choker | Vertical Basket | 60° | 45° | 30° | |

| 1 | 2,600 | 2,100 | 5,200 | 4,500 | 3,700 | 2,600 |

| 2 | 5,300 | 4,200 | 10,600 | 9,200 | 7,500 | 5,300 |

| 3 | 8,400 | 6,700 | 16,800 | 14,500 | 11,900 | 8,400 |

| 4 | 10,600 | 8,500 | 21,200 | 18,400 | 15,000 | 10,600 |

| 5 | 13,200 | 10,600 | 26,400 | 22,900 | 18,700 | 13,200 |

| 6 | 16,800 | 13,400 | 33,600 | 29,100 | 23,800 | 16,800 |

| 7 | 21,200 | 17,000 | 42,400 | 36,700 | 30,000 | 21,200 |

| 8 | 25,000 | 20,000 | 50,000 | 43,300 | 35,400 | 25,000 |

| 9 | 31,000 | 24,800 | 62,000 | 53,700 | 43,800 | 31,000 |

| 10 | 40,000 | 32,000 | 80,000 | 69,300 | 56,600 | 40,000 |

| 11 | 53,000 | 42,400 | 106,000 | 91,800 | 74,900 | 53,000 |

| 12 | 66,000 | 52,800 | 132,000 | 114,300 | 93,300 | 66,000 |

| 13 | 90,000 | 72,000 | 180,000 | 155,900 | 127,300 | 90,000 |

GENERAL NOTES:

(a) Roundslings are identified by the vertical rated load shown on the sling identification. The size numbers in the first column have been adopted by the Web Sling & Tie Down Association to describe certain polyester roundslings. They are included for references only. Other polyester roundslings may have different vertical rated loads.

(b) Color guidelines for polyester roundsling covers are widely used to indicate the vertical rated load of roundslings; however, this is not followed by some manufacturers. Always select and use roundslings by the rated load as shown on the sling identification; never by color.

(c) For choker hitch, the angle of choke is 120 deg or greater.

Fig. 1 Alloy Steel Chain Slings: Configurations, Components, and Hitches

| Angle of choke, deg | Rated Capacity, % [Note (1)] |

|---|---|

| Over 120 | 100 |

| 90-120 | 87 |

| 60-89 | 74 |

| 30-59 | 62 |

| 0-29 | 49 |

NOTE:

(1) Percent of sling rated capacity in a chocker hitch.

Fig. 2 Angle of Choke

Fig. 3 Angle of Loading

Fig. 4 D/d Ratio

The symbols below represent load or support surfaces in contact with the rope sling. The contact surface diameter divided by the rope diameter is designated D/d ratio as described in Fig. 6. Tables 18, 19, and 20 are based on the D/d ratios indicated below.

| Represents a contact surface which has a diameter of curvature at least double the diameter of the rope from which the sling is made. | |

| Represents a contact surface which has a diameter of curvature at least 8 times the diameter of the rope. | |

| Represents a load in choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface is at least double the diameter of the rope. |

General Note: Legs 5 deg or less from vertical may be considered vertical. For slings more than 5 deg vertical, the actual angle shall be used.

Fig. 5 Hitch Types for Synthetic Rope Slings

GENERAL NOTE: Legs 5 deg or less from vertical may be considered vertical. Slings with horizontal angles less than 30 deg should not be used.

Fig. 5 Hitch Types for Synthetic Rope Slings (cont'd)

Fig. 6 D/d Ratio

Sling made with a triangle fitting on one end and a slotted triangle choker fitting on the other end. It can be used in a vertical, basket, or choker hitch.

Type I

Sling made with a triangle fitting on both ends. It can be used in a vertical or basket hitch only.

Type II

Sling made with flat loop eye on each end with loop eye opening on same plane as sling body. This type of sling is sometimes called a flat eye-and-eye, eye-and-eye, or double-eye sling.

Type III

Sling made with both loop eyes formed as in Type III, except that the loop eyes are turned to form a loop eye which is at a right angle to the plane of the sling body. This type of sling is commonly referred to as a twisted-eye sling.

Type IV

Endless sling, sometimes referred to as a grommet. It is a continuous loop formed by joining the ends of the webbing together.

Type V

Return-eye (reversed-eye) sling is formed by using multiple widths of webbing held edge-to-edge. A wear pad is attached on one or both sides of the sling body and on one or both sides of the loop eyes to form a loop eye at each end which is at a right angle to the plane of the sling body.

Type VI

Fig 7 Synthetic Webbing Slings

GENERAL NOTE: Ensure that fittings designed for synthetic slings are used.

Fig. 8 Synthetic Fiber Rope Slings