Mustang WCK Projects

OSHA Strategic Partnership

Between

Occupational Safety and Health Administration

Birmingham Area Office,

University of Alabama SafeState

On-site Consultation Program

And

Holder Construction Group, LLC

-

PURPOSE/SCOPE

This Partnership was developed jointly by the Occupational Safety and Health Administration (OSHA), the University of Alabama - SafeState On-site Consultation Program (UA SafeState) and Holder Construction Group, LLC (Holder). This Partnership will cover the construction of the Mustang WKC Projects (Project), located in Bridgeport, Alabama. The common objective and goals of the Partnership include the following:

- Reduced injuries and illnesses;

- Increased safety and health training;

- Reduced overexposure to health hazards; and

- Increased number of employers with appropriate safety and health management systems.

This Partnership is consistent with OSHA's long-range efforts to develop a contractor/government Partnership approach to safety management. It allows for better use of OSHA resources and innovation in safety management, and also encourages more participation in the safety process from the construction industry.

To facilitate the goal of reducing occupational related fatalities and serious injuries within the construction industry, OSHA and Holder Construction Group, LLC, will implement a Partnership under the OSHA Strategic Partnership Program (OSPP). This Partnership covers the Project, which is a 465 acre (+/-) greenfield site located in Bridgeport, Alabama. The project consist of multiple two-story 60MW (megawatt) data center facilities and ancillary support buildings. Each data center is a two-story structural steel building, with precast skin, exterior electrical and a mechanical cooling plant. The project owner and design team are strictly confidential.

By combining their efforts, skills, knowledge and resources, OSHA, the University of Alabama - SafeState On-site Consultation Program (UA SafeState) and Holder expect to reduce exposure to hazards and thereby decrease the possibility of serious injuries and fatalities at Mustang WKC Projects.

-

IDENTIFICATION OF PARTNERS

The Partnership participants will include:

- Occupational Safety and Health Administration;

- University of Alabama - SafeState On-site Consultation Program (UA SafeState); and

- Holder Construction Group, LLC (the General Contractor)

-

GOALS/STRATEGIES/PERFORMANCE MEASURES

The primary objective of this Partnership is to create a working relationship that focuses on preventing work-related fatalities, controlling or eliminating serious workplace hazards, and establishing a foundation for the development of an effective safety and health program. The goals employed to achieve these results will include the following:

GOALS STRATEGIES MEASURES Reduce the total number of injuries and illness cases by 10 percent, thereby providing a safe and healthy work environment for employees at the Project. - Reviewing the OSHA 300 log data of the Partnership participants. Reviewing injury and illness trends and implementing effective corrective action(s).

- Calculating the employer's Total Case Incident Rate (TCIR) and Days away from work, restricted, or job transferred (DART) 1 rates.

- Comparing this data with the baseline rates for the Partnership.

- This goal will be measured by the number of companies participating in the Partnership, which reduce their TCIR and DART rates below the baseline for the partnership.

- Baseline will be established by the 2016 BLS Rates for Non-Residential Construction NAICS 2362, which is 2.4 and 1.3.

Increase the number of employees, employers and supervisors who are provided effective safety and health training, such as the OSHA 10-hour course. - Evaluation of the employers that establish effective safety and health training programs.

- Evaluation of the employers that provide employees with OSHA 10-hour/ OSHA 30-hour training.

- Measure the number of employers with effective safety and health training programs.

- Measure the number of managers, supervisors and employees provided with OSHA 10-hour/ OSHA 30-hour training compared to the (baseline) initial year of the Partnership.

Conduct effective self-inspections, sampling, monitoring, training and consultative activities in areas where employees might be exposed to health hazards such as the following: hazardous noise levels; lead; silica; asbestos; ergonomic stressors; and other health-related hazards.

The overall outcome of this goal should be the reduced overexposure of workers to health hazards, as well as a reduced injury and illness rate.

- Track health hazard related program improvements, as well as training focused on the prevention of health hazards.

- The Holder Team will track the number of self-inspections and site audits, as well as the number of health hazards identified during these activities.

A comparison will be made between the number of health hazards identified during self-inspections and audits conducted during the (baseline) initial year of the Partnership. Effectively control workplace hazards by increasing the number of construction companies with safety and health management systems. - Reviewing the number of employers that receive comprehensive consultation visits.

- Reviewing the number of employers that work with the Partnership to develop and implement comprehensive safety and health management systems.

Measure the number of project employers/subcontractors that develop and implement effective safety and health management systems, as a result of participating in the Partnership, compared to the (baseline) initial year of the Partnership. i Days Away from work, Restricted, or job Transferred (DART) rate: This includes cases involving days away from work, restricted work activity, and transfers to another job. It is calculated based on (N / EH) x (200,000) where N is the number of cases involving days away, and/or restricted work activity, and/or job transfer; EH is the total number of hours worked by all employees during the calendar year; and 200,000 is the base number of hours worked for 100 full-time equivalent employees. For example: Employees of an establishment including management, temporary, and leased workers worked 645,089 hours at this worksite. There were 22 injury and illness cases involving days away and/or restricted work activity and/or job transfer from the OSHA 300 Log (total of column H plus column I). The DART rate would be (22 / 645,089) x (200,000) = 6.8 -

MANAGEMENT AND OPERATION

-

Holder:

- Establish a jobsite safety team, consisting of a representative of all primary contractors on site, in order to develop an understanding and awareness that all accidents are preventable. This action will be accomplished by implementing a comprehensive safety and health management system, which includes:

- Management commitment and employee involvement;

- Hazard analysis;

- Hazard prevention and control; and

- Arrangement of training assistance for other stakeholders on site.

- Mentor subcontractors in safety and health management systems. Subcontractors shall include all multi-tiered subcontractors that arrive for work on the site.

- Where the potential for airborne silica exposure exists, require the use of wet-cutting or soft-cutting techniques and/or a dust collection system and, when employee exposure levels require, mandatory use of approved respiratory protection. Additionally, where the potential for airborne silica exposure exists, personal air monitoring will be conducted to assess employee exposure levels. Where the potential for other health issues exist (i.e., carbon monoxide, lead, or large-scale use of chemicals in the building interior during floor finishing), Holder will coordinate with the subcontractor responsible for creating the hazard and ensure that air monitoring is accomplished to assess employee exposure levels.

- Enforce safety rules and regulations. This role includes holding contractors, subcontractors, and employees accountable for following safety rules and regulations and the ability to remove a contractor's employees and supervisors from the job site, if necessary.

- Ensure that a competent person performs a risk assessment of all fall hazards. The probability and severity of occurrence for each identified hazard will be evaluated to eliminate or reduce the risk through engineering or administrative controls to a level as low as possible. Regarding fall hazard risk assessments:

- Critical risks will not be tolerated. A critical risk is defined by work that contains high probability in occurrence and high severity in consequence. No work will be performed until action is taken to reduce the level of risk to as low as reasonably feasible.

- Employees performing overhand bricklaying and related work above lower levels must be adequately protected from falls. No controlled access zone will be allowed. Additionally, no warning-line system or safety monitoring system will be used on site.

- All personnel exposed to a fall greater than 6 feet shall conform to Holder's 100 percent tie-off for all employees with fall exposure at heights at six feet or greater (see Site-Specific Safety Action Plan (SSSAP)).

- To the extent feasible, serious ergonomic hazards will be identified and corrected.

- Ensure that ground fault circuit interrupters (GFCI) are used to protect all electrical circuits that are used for work. All contractors will ensure that employees are protected by the use of a GFCI at all times.

- Holder's Superintendent and on-site safety professional will serve as a point of contact, and will monitor safety and health at the site and progress toward achievement of the Partnership goals.

- Holder's Superintendent and on-site safety professional will ensure that daily safety audits are conducted, and will review the subcontractor daily log books, noting any hazards found, and then discussing the finding at the weekly coordination/subcontractor meeting.

- Conduct and document job site safety meetings/toolbox talks on a weekly basis.

- Submit monthly accident reports to the Mustang WCK Projects Strategic Partnership Safety Committee (Safety Committee), including first aid, injury, property damage and near miss reports.

- Holder's superintendent/project manager or safety professional will lead, coordinate and conduct a comprehensive site audit on a weekly basis. Safety Committee and subcontractor members will participate in the site safety audit. If non-compliant activity or hazards are discovered, immediate correction is required. Holder will document the corrective action taken and share this information with OSHA during the monthly update meetings.

- Audit the Partnership and make recommendations for improvement.

- Share the results of jobsite inspections and information concerning near misses with all workers. Near misses and daily safety audits will be discussed during tool box talks.

- Ensure that no employees are allowed to work directly below a suspended load except for situations where no other safe alternative may exist. In these rare cases, the following criteria must be met:

- Materials being hoisted shall be rigged to prevent unintentional displacement.

- Hooks with self-closing safety latches or their equivalent shall be used to prevent components from slipping out of the hook.

- All loads shall be rigged by a qualified rigger.

- Appropriate use of tag lines will be utilized to minimize work below suspended loads.

- Require the use of appropriate personal protective equipment. Hard hats are mandatory. All employees on site shall wear high-visibility reflective clothing. A 100 percent eye protection program will be implemented and gloves must be worn when hand injuries are likely to occur.

- Ensure that all signs and warnings are posted in English and Spanish (as well as any other language deemed necessary by the Holder Team).

- Implement an effective Heat Illness Prevention Program (Heat Program) to educate workers about the hazards of working outdoors in the heat and steps needed to prevent heat-related illnesses.

- Provide all data to OSHA that is needed for the annual OSHA Strategic Partnership Program (OSPP) evaluation report.

- Establish a jobsite safety team, consisting of a representative of all primary contractors on site, in order to develop an understanding and awareness that all accidents are preventable. This action will be accomplished by implementing a comprehensive safety and health management system, which includes:

-

Subcontractors:

- Appoint a representative to the site Safety Committee who will be responsible for resolving job safety matters and serving as a liaison to Holder's superintendent and safety professional. Every subcontractor will have a person available to participate in the Safety Committee. Participation in this committee will consist of, but will not be limited to, participation in the Project Team Safety walkthroughs and monthly safety update meetings.

- Participate in the monthly Safety Committee/subcontractor meeting and safety audits. If non-compliant activity or hazards are discovered, immediate correction is required. Abatement methods and verification must be submitted to Holder's on-site safety manager, who will document the correction taken and share this information during the monthly update meetings.

- Conduct jobsite safety inspections for employees under their supervision. These jobsite safety inspections will be in addition to the general inspections that are to occur daily. If non-compliant activity or hazards are discovered, immediate correction is required. Documentation of abatement methods and verification must be submitted to Holder's onsite Safety Manager.

- Share the results of jobsite inspections with all workers by posting them in the project office and notifying all workers of the location of the results.

- OSHA will:

- Participate, to the extent resources permit, in the monthly Safety Committee/subcontractor meetings, but will not participate in the walk around inspection, except that the verification visits (see Section VIII. OSHA Verification below) may be scheduled as part of the weekly walk around inspection.

- Serve as a resource and liaison for Partnership participants and also assist with safety and health training, as resources permit.

- Give priority to the construction project, as resources permit, when technical assistance is needed.

- Audit the monthly reports/documents and make recommendations for improvements in meeting Partnership goals.

- Conduct inspections in accordance with section VIII of this Partnership.

- Conduct the annual Partnership evaluation report in accordance with section VI of this Partnership.

-

UA SafeState:

- Give priority consideration to requests for services to small contractors who are engaged in work at the project.

- Appoint a representative to the Safety Committee and participate in meetings to the extent resources allow.

- To the extent feasible, conduct quarterly safety and health surveys of the project, which may include performing personal air monitoring to assess employee exposure levels to chemicals (such as silica, carbon monoxide, heavy metals, isocyanates, hexavalent chromium and other noted chemical hazards).

- To the extent feasible, conduct personal noise monitoring to assess employee exposure.

-

-

SAFETY AND HEALTH MANAGEMENT SYSTEM

Holder will use its system to collect and analyze injury and illness trends (including near-miss incidents) by all contractors performing work at the site. This data will be used as a tool to ensure continual safety and health improvement at the site. Holder will manage this Partnership effectively by implementing a comprehensive jobsite safety and health management system, which will include the following components:

- Holder will complete a risk assessment prior to exposing employees (including contractors' employees) to potential safety and health hazards. This will be accomplished by the use of a Crew Work Plan - Risk Assessment (CWP) form (see Pre-Task Plan Card).

- Work with OSHA and Safety Committee members to provide the resources to conduct initial monitoring for toxins, which are anticipated to be present during construction of this project (silica, etc.). Employee exposures (during activities which may produce these hazards) will be assumed and respiratory protection worn until the results of the initial monitoring studies are received, which demonstrate no exposure problems (or site-based surveys show no hazard exists). Holder will endeavor to ensure that no work with these materials will occur, thus preventing any exposure.

- Daily audits will be performed by all contractors on site. In addition, on a weekly basis, a comprehensive audit of the jobsite will be performed, with the participation of a representative of each contractor currently working on site. Any hazards found during the audits will be corrected promptly. Items noted on the audit will be annotated on a daily log. When hazards cannot be corrected immediately, they will be tracked until abatement is completed. Employees exposed to these hazardous conditions will be informed of the hazard and effective interim control measures will be implemented. A record will be kept of all hazards found during the weekly audits and the number of hazards corrected as a result of the weekly audits.

- Implement an aggressive Fall Protection Plan to include fall protection in all cases where work is being performed 6 feet or more above lower surfaces.

- Ensure employees receive training as follows:

- Holder workers will receive OSHA 10-hour training, and all Holder supervisors will receive OSHA 30-hour training. Holder will work with all subcontractors to provide or assist in providing their safety designee with OSHA 10-hour training.

- All employees will receive a site-specific construction safety orientation covering jobsite safety and health issues, procedures relative to the work being performed, as well as the requirements outlined in the Partnership. In addition, employees shall receive training on the content of the Site-Specific Safety Action Plan for operations they will encounter. This may require periodic retraining of employees on the content of the Site-Specific Safety Action Plan as specific parts of the Plan become relevant at new phases of construction. This material will be provided by Holder to the subcontractors' designated safety representative for completion (see Appendix 2 - SSSAP).

- Safety and health training, including the OSHA 10 and 30-hour courses, will be provided to all workers in English and Spanish (as well as any other language deemed necessary by the Holder Team). Either effective translators or bi-lingual instructors will be utilized to perform this training.

- Additional hazard-specific training will be conducted on an as- needed basis.

- Subcontractors utilizing other instructors for competent person, OSHA 10/30-hour, and equipment training must provide a valid certification card showing completion of the course. Subcontractors have primary responsibility for providing the safety and health training.

- Subcontractors will be required to develop an adequate safety and health management system and must submit them to Holder for evaluation.

- Ensure health-related issues which occur during the course of the project are adequately addressed by Holder and/or the affected subcontractors, with the assistance of OSHA as its resources permit. All health-related issues will be discussed monthly during the Partnership update meetings.

- An effective hearing conservation program, including noise monitoring and implementation of engineering controls, where possible, will be implemented by Holder's Safety Department.

- An effective environmental monitoring program will be implemented to control airborne hazards, such as silica, and will include personal monitoring, employee training, implementation of engineering controls where possible, and the use of respiratory protection when necessary. Previous site-based data will be considered acceptable.

- Ensure compliance with the NFPA 70E when working on live electrical equipment, including training and the availability and use of personal protective equipment. A permit system will be implemented whenever work around live electrical systems will be done to ensure the implementation of appropriate protective measures prior to exposure. The permit form includes requirements for pre-task review and lock out/tag out procedures to be followed.

- Ensure all equipment is adequately guarded.

-

ANNUAL EVALUATION

The Partnership will be evaluated on an annual basis through the use of the Strategic Partnership Annual Evaluation Format as specified in Appendix C of OSHA Instruction CSP 03-02-003, OSHA Strategic Partnership Program for Worker Safety and Health.

Holder will be responsible for gathering required participant data to evaluate and track the overall results and success of the Partnership. This data will be shared with OSHA. OSHA will be responsible for writing and submitting the annual evaluation.

-

INCENTIVES

Participant incentives from OSHA may include:

- Maximum penalty reductions for good faith and history, to the extent allowed by the OSHA Field Operations Manual (FOM), OSHA Instruction CPL 02-00-160 (August 2, 2016).

- If a citation with penalties is issued, the Area Director has the authority to negotiate the amount of an additional penalty reduction as part of the informal conference settlement agreement, which is consistent with OSHA's current policy regarding this matter.

- The OSHA enforcement verification inspections will be conducted in accordance with Section VIII, OSHA Verification Enforcement Inspections.

- An OSHA focused inspection is available where the Partnership participant has an effective safety and health management system fully compliant with 29 CFR 1926.20 and 29 CFR 1926.21 (For additional details refer to the August 22, 1994, memo signed and issued by former Deputy Assistant Secretary for OSHA James Stanley, which was revised in September 20,1995.

-

OSHA VERIFICATION

- Verification Enforcement Inspections: OSHA will conduct the initial verification enforcement inspection no sooner than two months, but within three months after Partnership participants formally enter into this agreement. During this period, participants should develop and implement the safety and health management systems required under this Agreement. After this period, OSHA will conduct an annual verification enforcement inspection. Compliance officers that are familiar with the Mustang WCK Projects Strategic Partnership will conduct the verification inspections. Employee rights under the Occupational Safety and Health Act (OSH Act) will be afforded. If during the verification enforcement inspections, OSHA personnel identify serious hazards, the scope of the inspection may be expanded.

- Complaint/Referral Investigations: This Partnership provides for the immediate response to each allegation of a safety or health hazard brought to its attention by any person. Upon a finding that an allegation is valid, the employer shall promptly abate the hazard.

- OSHA agrees that a copy of each non-formal complaint/referral related to the work site and filed with OSHA will be delivered to the Mustang WCK Projects Management office by a Compliance Safety and Health Officer (CSHO), forwarded by fax, or sent via email. In accordance with applicable law, the name of the complainant requesting confidentiality will not be revealed. Holder agrees to investigate these complaints, regardless of the employer involved and provide OSHA with a written response within five-working days of receiving the non-formal complaint/referral.

- Accident Investigations: Employers engaged in this Partnership recognize that OSHA fully investigates accidents involving a fatality or serious physical harm. If during the course of the investigation OSHA determines that the incident resulted from violations of OSHA standards, the Partnership may be terminated.

-

WORKER INVOLVEMENT / WORKER AND EMPLOYER RIGHTS

This Partnership does not preclude employees and/or employers from exercising any right provided under the OSH Act (the Act), nor does it abrogate any responsibilities of the Partnership participants to comply with rules and regulations adopted pursuant to the Act.

Holder will ensure employee involvement by establishing an employee Safety Committee that will meet on a monthly basis to share the results of jobsite inspections, information concerning accidents and near misses, suggestions for improvement and recommendations for training for the general workforce. The Partnership members' management and supervisors will also continue to discuss near misses and daily safety audits during toolbox talks.

-

TERM OF PARTNERSHIP

It is understood that this Partnership shall be in effect until completion of construction activities at the Mustang WCK Projects site. If any signatory of this Partnership wishes to terminate their participation prior to the established termination date, a written notice of the intent to withdraw must be provided to all other party(s), which provides a 30-day notice.

If OSHA chooses to withdraw its participation in the Partnership, the entire Partnership is terminated. Any party may also propose modification or amendment of the agreement. Changes may be implemented, if all parties are in agreement that the changes are in the best interest of the Partnership.

-

XI. MUSTANG WCK PROJECTS STRATEGIC PARTNERSHIP

Partnership Signing Date: _________________________

Ramona Morris

Area Director

Occupational Safety & Health Administration (OSHA)

John Redmond

VP-Operations

Holder Construction Group, LLC

Corey Lemming

Senior Project Manager

Holder Construction Group, LLC

Jorge Cisneros

Corporate Safety Director

Holder Construction Group, LLC

Chris Paine

Senior Superintendent

Holder Construction Group, LLC

Matt Hollub

University of Alabama - SafeState

On-site Consultation Program

APPENDIX 1

Safety Pre-Task Plan Card

HOLDER CONSTRUCTION COMPANY

Actividad:________________________________________________________________

Completado por:___________________________

| Work Steps and Tasks/Pasos de la tarea-trabajo Describe the tasks-Describa la tarea/steps involved in order pasos del trabajo en orden |

Hazards Identified for each Task/Step Riesgod Identificados para cada paso del trabajo |

Control/Safe Work Procedures for each Task/Step Controls to be implemented (consider the hiearchy of hazard controls) Controles/procedimiento de sefuridad a ser implementados |

|||

| Hazards Checklist/Riesgos | |||||

□ |

Can someone be struck or contacted by anything while doing this job? Puede alguien ser impactado o contactado en este trabajo/tarea? |

□ |

Can someone slip, trip or fall? Puede alguien resbalarse o caerse? |

□ |

Can someone fall into anything? Puede alguien caerse en algo? |

□ |

Can someone strike against or make contact with any physical hazards? Puede alguien estar expuesto a riesgos fisicos? |

□ |

Can someone strain or overexert? Puede alguien estirarse o sobre-extenderse? |

□ |

Is there other Trades working near? Hay otras companias trabajando en el area? |

□ |

Can someone be exposed to any hazardous conditions? Puede alguier estar expuesto a condiciones riesgozas? |

□ |

Can someone be caught in anything? Puede ser alguien atrapado en algo? |

□ |

Can someone injure someone else? Puede alguien lesionar a otra persona? |

Any Hazards/Riesgos:

Yes/Si - No/No

Explain/Explique:

| Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: |

| Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: |

| Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: |

| Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: | Name/Nombre: | Initials/Iniciales: |

**I have read and understand the Safety Pre-Task Plan and agree to abide by its safety practices. Introduction of a new task that is not listed in the job activities above will require a new Pre-Task Plan. I realize that violation of the job site safety rules may lead to disciplinary action, including suspension and/or termination. I further understand that if I am injured in the course of my work, I will report the injury to my supervisor immediately.

**He leído y entendido el analisis antes de trabajar de seguridad y estoy de acuerdo con sus prácticas de seguridad. La introduccíon de una nueva tarea que no aparece en las actividades de trabajo anterior requerirá un nuevo analisis. Me doy cuenta de que la violación de las reglas de seguridad del lugar de trabajo puede dar lugar a medidas disciplinarias, incluyendo las suspensión y / o terminación. Además, entiendo que si me lesiono en el curso de mi trabajo, voy a lesión a mi supercisor inmediatamente.

APPENDIX 2

SITE-SPECIFIC SAFETY ACTION PLAN (SSSAP)

Project: Mustang WCK Projects

Location: Bridgeport, Alabama

PROJECT CONTACTS:

| First Name | Last Name | Title | Mobile Phone | |

| Bill | Thomason | Superintendent | bthomason@holder.com | 770-558-5784 |

| Brandon | Harper | Manager | bharper@holder.com | 678-778-1900 |

| Christopher | Paine | Senior Superintendent | cpaine@holder.com | 404-386-1798 |

| Corey | Lemming | Senior Project Manager | clemming@holder.com | 678-427-4547 |

| Daniel | Chapman | Senior Engineer | dchapman@holder.com | 205-520-6409 |

| Daniel | Morales | Senior Safety Director | dmorales@holder.com | 770-480-8440 |

| John | Redmond | Vice President | jredmond@holder.com | 602-999-7402 |

| Jonathan | Pope | Superintendent | jpope@holder.com | 803-309-8210 |

| Jorge | Cisneros | Corporate Safety Director | jcisneros@holder.com | 404-787-6782 |

| Rodney | Cook | Senior Safety Coordinator | rcook@holder.com | 470-295-7775 |

| Marco Polo | Chantres | Senior Safety Coordinator | mchantres@holder.com | 678-265-7147 |

Project Narrative:

The Widows Creek Project is a 465 +/- acre greenfield site located in Bridgeport, Alabama. The project will consist of multiple 2-story 60MW (megawatt) Data Center facilities and ancillary support buildings. Each data center is a two-story structural steel building with precast skin. Each data center is supported by an exterior electrical and mechanical cooling plant. The project owner and design team are strictly confidential.

Scope of Work:

Holder's primary work load will consist of construction management. Holder will also be self-performing the installation of all self-preform concrete. For this work, Holder Construction's project team will employee many carpenters and labors. In addition to self-performing the concrete on this project, the employees will also assist in maintaining safety on the project. All site employees will be required to complete daily Crew Work Plan meetings and will be supervised by a site foreman. The superintendent and Safety Professional shall have the responsibility of enforcing safety on a daily Basis. Holder will assist subcontractors with site coordination and planning. In addition to Holder's Safety professional all major trades i.e. MEP, Steel, Pre-Cast and Site Work are contractually required to provide a minimum of one full time Safety Professional.

Public Protection:

During non-working hours the jobsite's gates shall be locked. No trespassing signs shall be posted in conspicuous areas on the perimeter of the project to warn the public to stay out of the site. All visitors will be required to sign-in at the Holder office trailer. Holder Construction management will be responsible for making sure all visitors are accompanied on the project and are informed of site personal protective equipment requirements.

Orientation:

Site specific orientation will be held on an as needed basis. All employees who are or will be working on site must attend this training prior to beginning work on the project. This training will encompass site safety, procedures, hazard communication, emergency planning, and basic construction safety. A site-specific orientation sticker and Badge will be issued to all employees who attend this training and complete safety acknowledgment form.

Site Logistics:

All haul roads will be built and maintained by site contractor (CS Beatty). Laydown areas will be provided to each subcontractor as needed. Work will only take place in the day time unless light towers are installed to provide workers with adequate visibility. Wash out areas will be provided to concrete trucks and pump trucks in areas that will not affect traffic. Holder will manage concrete, steel, and trash dumpsters on the project.

Crane Operations:

Only certified crane operators will be allowed to operate cranes on site. Only qualified riggers/flaggers will be allowed to signal the crane and rig loads to be flown. Hand signals/radios will be used to communicate with the crane operator. Whistles will be used to alert all employees in the area that a pick is being made. All loads must have a non-conductive tag line attached. For mobile cranes, the swing radius of the crane must be barricaded at all times. Outriggers must have appropriate cribbing in place prior to any loads being flown.

If a crane's working radius encompasses active power lines, one of the following must be done:

- De-energize and ground the power lines (Must be done by the appropriate utility company)

- Maintain a minimum 20 feet safe approach distance

- Determine the voltage of the lines and follow safe approach distances Table 4.2 in SHEMS

Personal Protective Equipment:

Hard hats, high visibility vest or shirt, long pants, work boots, hand protection (Gloves) are gloves worn at all times or for tasks and safety glasses shall be worn at all times. This practice will be enforced on a daily basis as per Holder's safety policy. Holder will monitor subcontractors PPE at all times. Failure to wear mandatory PPE will result in verbal and written warning. If problems persist employees may be suspended or removed from the project.

Fall Protection:

All subcontractors will be required to have fall protection when exposed to a fall of 6' or greater. Holder has a zero-tolerance policy on fall protection infractions. Any employee observed violating the fall protection policy will be suspended from the project for a time period to be determined by the project team. Any further infractions by that employee will result in the employee's permanent removal from the project.

Each subcontractor is required to create a plan or system to address fall protection within their scope of work. These plans or systems are maintained in their company's site-specific safety plans. Each company's site-specific plan is kept at the Holder's office trailer.

Guardrails and Floor Opening Protection:

All guardrails, both wire rope and wooden, will be built to comply with Holder's SHEMS manual. The top railing will be at 42" +/– 3" and able to withstand a downward and outward force of 200 lbs. All railings will include a mid-rail set at 21" +/- 3"and able to withstand a force of 150 lbs. All guardrails that are in locations with work or foot traffic under them shall have toe-boards installed to prevent materials and tools from falling. This toe-board will be maintained until glass or precast concrete is set on the exterior of the building rendering them un-needed. If wire rope is used for guardrails, the wire rope must be at a minimum 3/8" diameter and flagged every 6'. The wire rope must be kept taut so it will be able to withstand a force of 200 lbs. and not sag below 39". Three clips must be installed at attachment points with 3" spacing between them.

All floor holes that are 2'' or greater will be covered with plywood and marked with hi-vis paint. Any holes over 8" will be identified with the words "Hole or Cover" and "Hoyo". In the case of depressions/recesses, the area will be flagged off to warn of the depression or the edge will be painted with hi-vis paint. All covers will be secured to prevent accidental displacement. Hole covers must be made to withstand twice the weight of worker, materials, and tools. No materials can be stored around or on top of hole covers. Covers must be kept well maintained and swept clean.

Roof Access:

Only authorized personal will be allowed on the roof. The Roofing subcontractor will be required to tie off when building the perimeter parapet wall before roofing activities begin. Fall protection will be required unless the parapet wall meets the height requirements of a guardrail system. If the parapet wall does not meet the requirements of a guardrail system, roofers will install a warning line 6' back from the edge of the roof. This warning line is only to be used by the roofer. All other subcontractors and Holder will be required to install a warning line 15' back from the roof if desired. If work is to take place beyond the warning line, a fall restraint or fall arrest system must be utilized.

Trenching and Utility Lines:

Holder and all subcontractors involved in trenching activities will be required to complete an excavation inspection for all excavations or trenches that are 4' or deeper. These reports will be completed daily, after rain storms, and after an event where conditions may change the characteristics of the trench. These are to be completed by a competent person and submitted to Holder. Trenches of significant depth or trenches that are obstructed from view shall be flagged to prevent accidental injury. Trenches 4' or greater in depth will have a means of access and egress (ladder, ramp, stair, etc.). All trenches shall be guarded or sloped when at a depth of 5' or greater. In compliance with SHEMS, Holder will assume all soils are type C until a soils engineer proves otherwise. Acceptable sloping for trenches or excavations 5' in depth or greater is 1.5:1. Any excavations or trenches 20' or greater in depth must have shoring/shielding system designed by a registered professional engineer.

All utilities will be located by a third party prior to any excavation or trenching activities. If utilities are present in the proposed excavation, soft digging methods must be utilized. Once utilities have been uncovered, they must be braced and protected from damage.

Safety Meetings and Training:

All subcontractors are required to attend the weekly project safety meeting. Holder will provide site specific orientation to all new employees on site. Orientation and hazard awareness training will be administered on an as needed basis. Safety Professional safety walks will be held biweekly and a supervisory member of each subcontractor is expected to attend. All deficiencies identified will be sent to the responsible subcontractors via emails. Subcontractors are required to respond to these deficiencies in writing within 48 hours. Failure to abate deficiencies or respond in writing could delay payment.

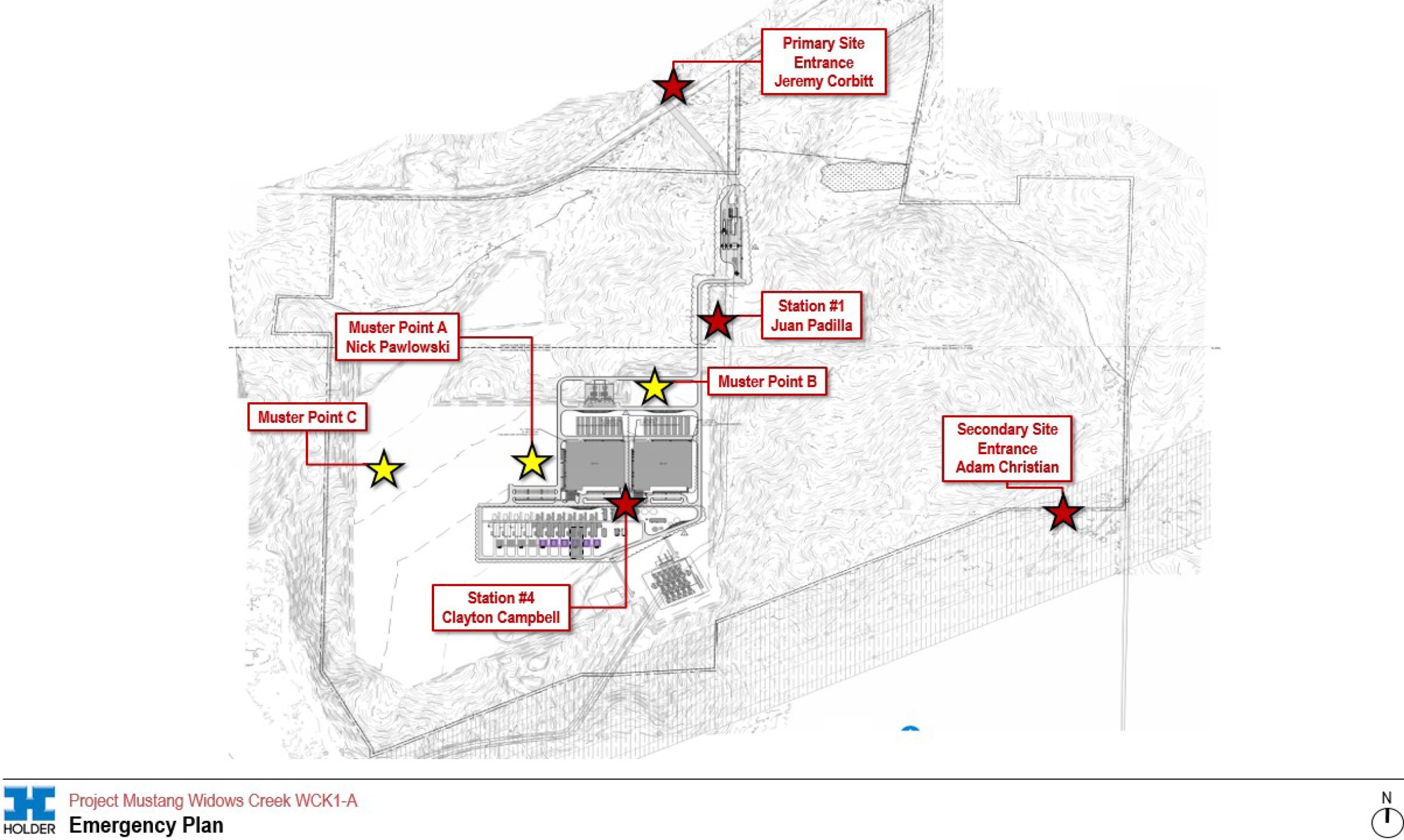

Emergency Action Plan:

Emergency Action Plan (EAP) will be posted in common areas around the project site (Holder trailer, job boards, break areas, etc.). The plan will be included in each employee's orientation. The EAP will be reviewed periodically during site wide safety meetings and scheduling meetings. This plan is subject to change, as the site progresses, all employees will be notified and retrained if any changes are made. Please see the site specific EAP on the following pages.

In Case of Accident

- Everyone Turn to Channel "1" on Radios

- Jon Pope and Bill Thomason Report To Scene of Accident & Provide Direction To Entire Team

- Katie Pope to Call "911" after Jon Pope or Bill Thomason Determine Medical Attention is Required

- On-site Nurse will Transport AED / Medical Supply Buggy to Scene and Provide Medical Aid

- Marco Chantres Will report to scene and Coordinate area for Emergency Personnel

- Jeremy Corbitt to Report to Primary Site Entrance and Maintain a Clear Path for Emergency Vehicles to Enter and Exit

- Adam Christian to report to Secondary Site Entrance and Maintain a Clear Path for Emergency Vehicles to Enter and Exit

- Juan Padilla To Take Emergency Personnel To Scene of Accident

- Clayton Campbell to report to south Road and Maintain Clear Access as Needed

- Jon Pope or Bill Thomason to make Announcement Over Job Site Radio After Emergency Vehicles Have Left Job Site

In Case of Emergency

- Katie Pope to Call "911"

- Jon Pope or Bill Thomason - Announcement To Job Site - 3 Long Air Horn Blast will be used to evacuate job site to Muster Points

- All Job Site Personnel Evacuate To Muster Point

- Roll Call To Be Taken After Evacuation of Building & Arrival To Muster Points

- Announcement Will Be Made With Further Instruction At Appointed Location

- Jon Pope or Bill Thomason - Notify Risk Management Immediately Following Accident Site is Stabilized

- Marco Chantres - Complete Accident Forms, Send to Risk Management Within 24 Hours of Accident

In Case of Severe Weather

- Jon Pope or Bill Thomason - Announcement To Job Site - 3 Long Air Horn Blast will be used to evacuate job site to Muster Points for Accountability

- Roll Call To Be Taken After Evacuation of Building and All Job Site Personnel to Evacuate Off-site to Find Shelter

April 19, 2018