- Standard Number:

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed. Note that our enforcement guidance may be affected by changes to OSHA rules. Also, from time to time we update our guidance in response to new information. To keep apprised of such developments, you can consult OSHA's website at https://www.osha.gov.

September 30, 2021

Albert Zhang, PE, PhD.

Global Engineering

6105 90th Street

Lubbock, TX 79424

Dear Mr. Zhang:

Thank you for your letter to the Occupational Safety and Health Administration (OSHA) regarding the applicability of 29 CFR § 1910.147, the Control of Hazardous Energy, and the use of pneumatic actuated fail closed valves as energy isolating devices. This letter constitutes OSHA’s interpretation only of the requirements discussed and may not be applicable to any questions not delineated within your original correspondence. The question you provided in your inquiry is paraphrased below. OSHA’s response follows your question.

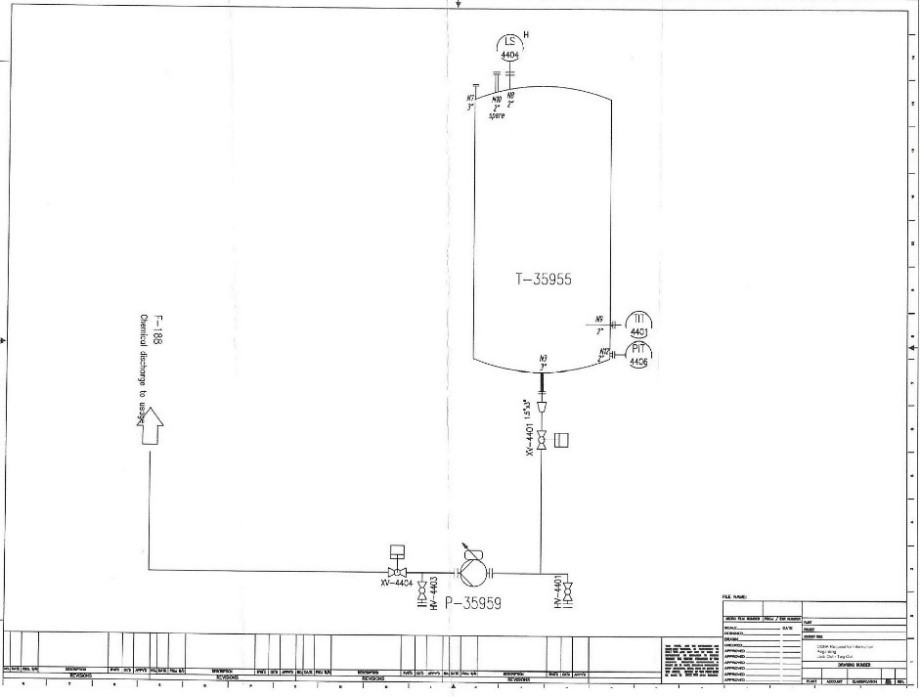

Background: An employer has a storage tank containing a hazardous chemical. An electric pump is installed with two pneumatic actuated fail closed valves installed: one valve is upstream from the pump and the other is downstream from the pump. In order to perform maintenance on the pump, both valves are closed and de-energized by disconnecting the pneumatic tubing supplying air to the valves. Locks are then applied to the ends of the tubes to prevent them from inadvertently opening.

In addition, you provided the below diagram of the system that your inquiry was based upon.

Note: The employer above provided technical data sheets on the pneumatic valves currently in use. It was discovered during the Agency’s research in the preparation of this letter that the manufacturer offers an additional “block-bleed valve module” that can be installed on the valves currently in use.

Question: Would it be acceptable to lock out the air supply to the pneumatic actuated valves in the manner described above in order to comply with 29 CFR § 1910.147?

Response: No. The pneumatic valve in its current configuration does not meet the definition of an energy isolating device as defined by 29 CFR § 1910.147(b) since it is not capable of being locked out.

An energy isolating device must have a hasp or other means of attachment to which, or through which, a lock can be affixed, or it has a locking mechanism built into it. OSHA understands that some valves and other energy isolating devices are not designed with an integral means of being locked, but they can be secured with chains, blocking braces or wedges, which then can be locked. The valve you have installed will not permit those measures of hazard control alone, making the addition of the block-bleed valve module necessary.

In regards to the disconnection of the pneumatic tubing to serve as an energy isolating device, please remember that in order to meet the requirements of 29 CFR § 1910.147(b), the device must be capable of being locked out without the need to dismantle, rebuild, or replace or permanently alter its energy control capability. Disconnecting the pneumatic tubing from the valve does not meet the definition of an energy isolating device capable of being locked out since “dismantling” (i.e.: disconnecting the pneumatic tubing from the air source) would be necessary for a zero energy state to exist.

As a reminder, according to 29 CFR § 1910.147(c)(2)(iii), after January 2, 1990, whenever replacement or major repair, renovation or modification of a machine or equipment is performed, and whenever new machines or equipment are installed, energy isolating devices for such machine or equipment shall be designed to accept a lockout device.

Thank you for your interest in occupational safety and health. We hope you find this information helpful. OSHA’s requirements are set by statute, standards, and regulations. Our letters of interpretation do not create new or additional requirements but rather explain these requirements and how they apply to particular circumstances. This letter constitutes OSHA’s interpretation of the requirements discussed. From time to time, letters are affected when the Agency updates a standard, a legal decision impacts a standard, or changes in technology affect the interpretation. To assure that you are using the correct information and guidance, please consult OSHA’s website at http://www.osha.gov. If you have any questions, please feel free to contact the Directorate of Enforcement Programs at (202) 693-2100.

Sincerely,

Kimberly Stille, Acting Director

Directorate of Enforcement Programs