- Part Number:1910

- Part Number Title:Occupational Safety and Health Standards

- Subpart:1910 Subpart P

- Subpart Title:Hand and Portable Powered Tools and Other Hand-Held Equipment

- Standard Number:

- Title:Guarding of portable powered tools.

- GPO Source:

Portable powered tool -

Portable circular saws.

Switches and controls.

All other hand-held powered tools, such as, but not limited to, platen sanders, grinders with wheels 2 inches in diameter or less, disc sanders with discs 2 inches in diameter or less, routers, planers, laminate trimmers, nibblers, shears, saber, scroll, and jig saws with blade shanks a nominal one-fourth of an inch wide or less, may be equipped with either a positive "on-off" control, or other controls as described by paragraph (a)(2)(i) and (ii) of this section.

Nominal in this subparagraph means ±0.05 inch.

Portable belt sanding machines. Belt sanding machines shall be provided with guards at each nip point where the sanding belt runs onto a pulley. These guards shall effectively prevent the hands or fingers of the operator from coming in contact with the nip points. The unused run of the sanding belt shall be guarded against accidental contact.

Cracked saws. All cracked saws shall be removed from service.

Grounding. Portable electric powered tools shall meet the electrical requirements of subpart S of this part.

Tool retainer. A tool retainer shall be installed on each piece of utilization equipment which, without such a retainer, may eject the tool.

Airhose. Hose and hose connections used for conducting compressed air to utilization equipment shall be designed for the pressure and service to which they are subjected.

Portable abrasive wheels -

General requirements. Abrasive wheels shall be used only on machine provided with safety guards as defined in paragraph (c) (1) through (4) of this section.

Exceptions. The requirements of this paragraph (c)(1) shall not apply to the following classes of wheels and conditions.

Mounted wheels used in portable operations 2 inches and smaller in diameter; (see definition § 1910.241(b)(1)); and

Exception. Safety guards on all operations where the work provides a suitable measure of protection to the operator may be so constructed that the spindle end, nut and outer flange are exposed. Where the nature of the work is such as to entirely cover the side of the wheel, the side covers of the guard may be omitted.

Exception. The spindle end, nut, and outer flange may be exposed on portable machines designed for, and used with, type 6, 11, 27, and 28 abrasive wheels, cutting off wheels, and tuck pointing wheels.

Cup wheels. Cup wheels (Types 6 and 11) shall be protected by:

Special "revolving cup guards" which mount behind the wheel and turn with it. They shall be made of steel or other material with adequate strength and shall enclose the wheel sides upward from the back for one-third of the wheel thickness. The mounting features shall conform with all regulations. (See paragraph (c)(5) of this section.) It is necessary to maintain clearance between the wheel side and the guard. The clearance shall not exceed one-sixteenth inch; or,

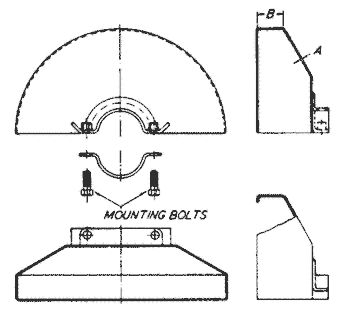

Vertical portable grinders. Safety guards used on machines known as right angle head or vertical portable grinders shall have a maximum exposure angle of 180°, and the guard shall be so located so as to be between the operator and the wheel during use. Adjustment of guard shall be such that pieces of an accidentally broken wheel will be deflected away from the operator. (See Figure P-4.)

Figure No. P-4

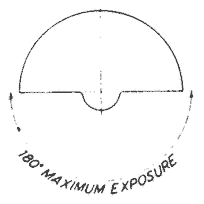

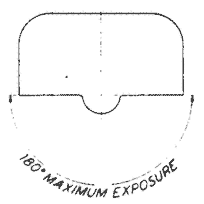

Other portable grinders. The maximum angular exposure of the grinding wheel periphery and sides for safety guards used on other portable grinding machines shall not exceed 180° and the top half of the wheel shall be enclosed at all times. (See Figures P-5 and P-6.)

Figure No. P-5

Figure No. P-6

Mounting and inspection of abrasive wheels.

Immediately before mounting, all wheels shall be closely inspected and sounded by the user (ring test, see subpart O, § 1910.215(d)(1)) to make sure they have not been damaged in transit, storage, or otherwise. The spindle speed of the machine shall be checked before mounting of the wheel to be certain that it does not exceed the maximum operating speed marked on the wheel.

Requirements for the use of flanges and blotters, see subpart O, § 1910.215(c).

Excluded machinery. Natural sandstone wheels and metal, wooden, cloth, or paper discs, having a layer of abrasive on the surface are not covered by this paragraph.

Explosive actuated fastening tools -

General requirements.

Operators and assistants using tools shall be safeguarded by means of eye protection. Head and face protection shall be used, as required by working conditions, as set forth in subpart I.

Inspection, maintenance, and tool handling -

High-velocity tools. Tools of this type shall have the characteristics outlined in (a) through (h) of this section.

The muzzle end of the tool shall have a protective shield or guard at least 3 1⁄2 inches in diameter, mounted perpendicular to and concentric with the barrel, and designed to confine any flying fragments or particles that might otherwise create a hazard at the time of firing.

The tool shall be so designed that it will not operate when equipped with the standard guard indexed to the center position if any bearing surface of the guard is tilted more than 8° from contact with the work surface.

Requirements for loads and fasteners.

Operating requirements.

When fastening other materials, such as a 2- by 4-inch wood section to a concrete surface, it is permissible to drive a fastener of no greater than 7⁄32-inch shank diameter not closer than 2 inches from the unsupported edge or corner of the work surface.

Power lawnmowers -

General requirements.

The words, "Caution. Be sure the operating control(s) is in neutral before starting the engine," or similar wording shall be clearly visible at an engine starting control point on self-propelled mowers.

Walk-behind and riding rotary mowers.

Openings in the blade enclosure, intended for the discharge of grass, shall be limited to a maximum vertical angle of the opening of 30°. Measurements shall be taken from the lowest blade position.

The total effective opening area of the grass discharge opening(s) shall not exceed 1,000 square degrees on units having a width of cut less than 27 1⁄2 inches, or 2,000 square degrees on units having a width of cut 27 1⁄2 inches or over.

The word "Caution." or stronger wording, shall be placed on the mower at or near each discharge opening.

Walk-behind rotary mowers.

The highest point(s) of the front of the blade enclosure, except discharge openings, shall be such that any line extending a maximum of 15° downward from the horizontal toward the blade shaft axis (axes) shall not intersect the horizontal plane within the blade tip circle. The highest point(s) on the blade enclosure front, except discharge-openings, shall not exceed 1 1⁄4 inches above the lowest cutting point of the blade in the lowest blade position. Mowers with a swingover handle are to be considered as having no front in the blade enclosure and therefore shall comply with paragraph (e)(2)(i) of this section.

Riding rotary mowers.

The highest point(s) of all openings in the blade enclosure, front shall be limited by a vertical angle of opening of 15° and a maximum distance of 1 1⁄4 inches above the lowest cutting point of the blade in the lowest blade position.

[39 FR 23502, June 27, 1974, as amended at 43 FR 49750, Oct. 24, 1978; 49 FR 5323, Feb. 10, 1984; 50 FR 4649, Feb. 1, 1985; 61 FR 9227, March 7, 1996; 70 FR 53929, Sept. 13, 2005; 72 FR 71070, Dec. 14, 2007]