- Part Number:1910

- Part Number Title:Occupational Safety and Health Standards

- Subpart:1910 Subpart H

- Subpart Title:Hazardous Materials

- Standard Number:

- Title:Flammable liquids.

- GPO Source:

For paragraphs 1910.106(a) to 1910.106(g)(1)(i)(e)(2), see 1910.106 - page 1.

[Reserved]

| Location | Class I Group D division | Extent of classified area |

|---|---|---|

| Tank vehicle and tank car:1 | ||

| Loading through open dome | 1 | Within 3 feet of edge of dome, extending in all directions. |

| 2 | Area between 3 feet and 5 feet from edge of dome, extending in all directions. | |

| Loading through bottom connections with atmospheric venting | 1 | Within 3 feet of point of venting to atmosphere extending in all directions. |

| 2 | Area between 3 feet and 5 feet from point of venting to atmosphere, extending in all directions. Also up to 18 inches above grade within a horizontal radius of 10 feet from point of loading connection. | |

| Loading through closed dome with atmospheric venting | 1 2 |

Within 3 feet of open end of vent, extending in all directions. Area between 3 feet and 5 feet from open end of vent, extending in all directions. Also within 3 feet of edge of dome, extending in all directions. |

| Loading through closed dome with vapor recovery | 2 | Within 3 feet of point of connection of both fill and vapor lines, extending in all directions. |

| Bottom loading with vapor recovery or any bottom unloading | 2 | Within 3 feet of point of connections extending in all directions. Also up to 18 inches above grade with in a horizontal radius of 10 feet from point of connection. |

| Drum and container filling: | ||

| Outdoors, or indoors with adequate ventilation | 1 | Within 3 feet of vent and fill opening, extending in all directions. |

| 2 | Area between 3 feet and 5 feet from vent or fill opening, extending in all directions. Also up to 18 inches above floor or grade level within a horizontal radius of 10 feet from vent or fill opening. | |

| Outdoors, or indoors with adequate ventilation | 1 | Within 3 feet of vent and fill opening, extending in all directions. |

| 2 | Area between 3 feet and 5 feet from vent or fill opening, extending in all directions. Also up to 18 inches above floor or grade level within a horizontal radius of 10 feet from vent or fill opening. | |

| Tank—Aboveground: | ||

| Shell, ends, or roof and dike area | 2 | Within 10 feet from shell, ends, or roof of tank, Area inside dikes to level of top of dike. |

| Vent | 1 | Within 5 feet of open end of vent, extending in all directions. |

| 2 | Area between 5 feet and 10 feet from open end of vent, extending in all directions. | |

| Floating roof | 1 | Area above the roof and within the shell. |

| Pits: | ||

| Without mechanical ventilation | 1 | Entire area within pit if any part is within a Division 1 or 2 classified area. |

| With mechanical ventilation | 2 | Entire area within pit if any part is within a Division 1 or 2 classified area. |

| Containing valves, fittings or piping, and not within a Division 1 or 2 classified area | 2 | Entire pit. |

| Pumps, bleeders, withdrawal fittings, meters and similar devices: | ||

| Indoors | 2 | Within 5 feet of any edge of such devices, extending in all directions. Also up to 3 feet above floor or grade level within 25 feet horizontally from any edge of such devices. |

| Outdoors | 2 | Within 3 feet of any edge of such devices, extending in all directions. Also up to 18 inches above grade level within 10 feet horizontally from any edge of such devices. |

| Storage and repair garage for tank vehicles | 1 | All pits or spaces below floor level. |

| 2 | Area up to 18 inches above floor or grade level for entire storage or repair garage. | |

| Drainage ditches, separators, impounding basins | 2 | Area up to 18 inches above ditch, separator or basin. Also up to 18 inches above grade within 15 feet horizontally from any edge. |

| Garages for other than tank vehicles | (2 ) | If there is any opening to these rooms within the extent of an outdoor classified area, the entire room shall be classified the same as the area classification at the point of the opening. |

| Outdoor drum storage | (2 ) | |

| Indoor warehousing where there is no flammable liquid transfer | (2 ) | If there is any opening to these rooms within the extent of an indoor classified are, the room shall be classified the same as if the wall, curb or partition did not exist. |

| Office and rest rooms | (2 ) |

1 When classifying the extent of the area, consideration shall be given to the fact that tank cars or tank vehicles may be spotted at varying points. Therefore, the extremities of the loading or unloading positions shall be used.

2 Ordinary.

Special enclosures.

The enclosure shall be substantially liquid and vaportight without backfill. Sides, top, and bottom of the enclosure shall be of reinforced concrete at least 6 inches thick, with openings for inspection through the top only. Tank connections shall be so piped or closed that neither vapors nor liquid can escape into the enclosed space. Means shall be provided whereby portable equipment may be employed to discharge to the outside any liquid or vapors which might accumulate should leakage occur.

Inside buildings.

Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), may be transferred from one container to another in lubrication or service rooms of a service station building provided the electrical installation complies with Table H–19 and provided that any heating equipment complies with paragraph (g)(6) of this section.

Dispensing into portable containers. No delivery of any Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), shall be made into portable containers unless the container is constructed of metal, has a tight closure with screwed or spring cover, and is fitted with a spout or so designed so the contents can be poured without spilling.

Dispensing systems —

Location. Dispensing devices at automotive service stations shall be so located that all parts of the vehicle being served will be on the premises of the service station.

Inside location. Approved dispensing units may be located inside of buildings. The dispensing area shall be separated from other areas in an approved manner. The dispensing unit and its piping shall be mounted either on a concrete island or protected against collision damage by suitable means and shall be located in a position where it cannot be struck by a vehicle descending a ramp or other slope out of control. The dispensing area shall be provided with an approved mechanical or gravity ventilation system. When dispensing units are located below grade, only approved mechanical ventilation shall be used and the entire dispensing area shall be protected by an approved automatic sprinkler system. Ventilating systems shall be electrically interlocked with gasoline dispensing units so that the dispensing units cannot be operated unless the ventilating fan motors are energized.

Emergency power cutoff. A clearly identified and easily accessible switch(es) or a circuit breaker(s) shall be provided at a location remote from dispensing devices, including remote pumping systems, to shut off the power to all dispensing devices in the event of an emergency.

Dispensing units.

Remote pumping systems.

Delivery nozzles.

Marine service stations —

Dispensing.

Tanks and pumps.

Tanks, and pumps not integral with the dispensing unit, shall be on shore or on a pier of the solid fill type, except as provided in paragraphs (g)(4)(ii) (b) and (c) of this section.

Piping.

Piping between shore tanks and dispensing units shall be as described in paragraph (c) of this section, except that, where dispensing is from a floating structure, suitable lengths of oil-resistant flexible hose may be employed between the shore piping and the piping on the floating structure as made necessary by change in water level or shoreline.

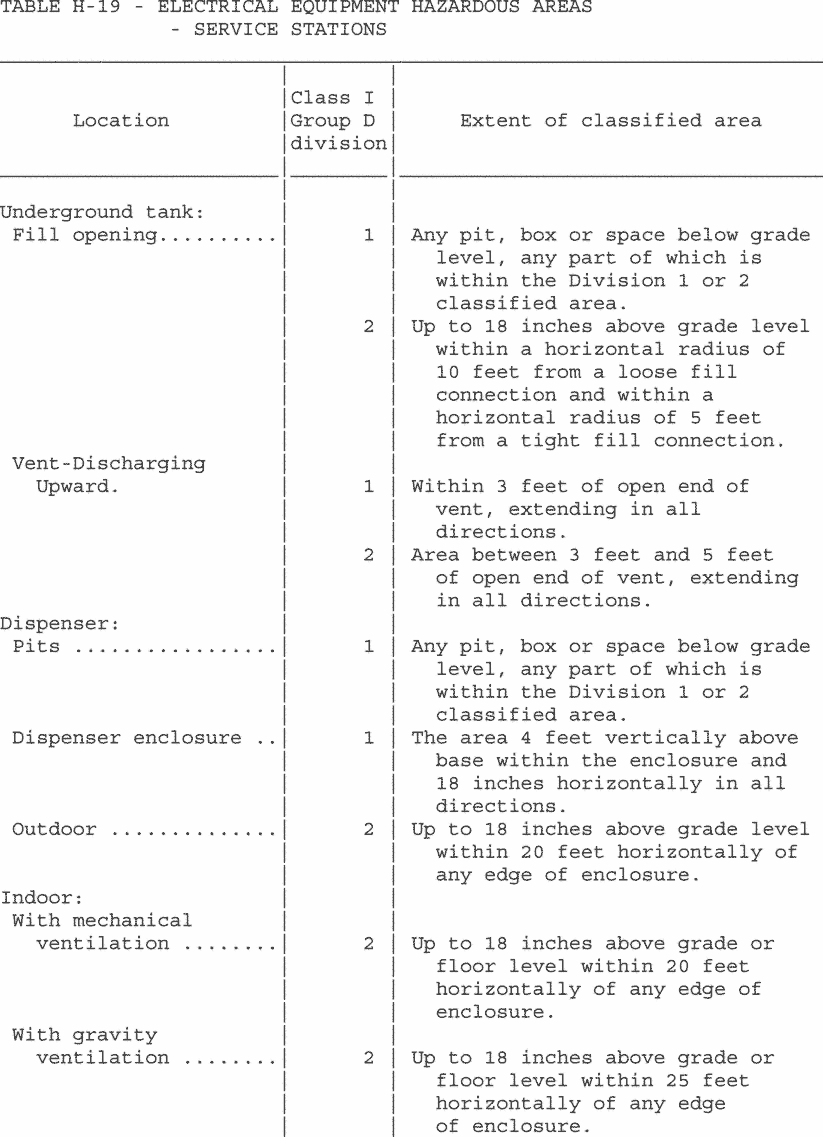

TABLE H-19 - ELECTRICAL EQUIPMENT HAZARDOUS AREAS - SERVICE STATIONS Underground tank: Fill opening 1 Any pit, box or space below grade level, any part of which is within the Division 1 or 2 classified area. 2 Up to 18 inches above grade level within a horizontal radius of 10 feet from a loose fill connection and and within a horizontal radius of 5 feet from a tight fill connection. Vent-Discharging Upward. 1 Within 3 feet of open end of vent, extending in all directions. 2 Area between 3 feet and 5 feet of open end of vent, extending in all directions. Dispenser: Pits 1 Any pit, box or space below grade level, any part of which is within the Division 1 or 2 classified area. Dispenser enclosure 1 The area 4 feet vertically above base within the enclosure and 18 inches horizontally in all directions. Outdoor 2 Up to 18 inches above grade level within 20 feet horizontally of any edge of enclosure. Indoor: With mechanical ventilation 2 Up to 18 inches above grade or floor level within 20 feet horizontally of any edge of enclosure. With gravity ventilation 2 Up to 18 inches above grade or floor level within 25 feet horizontally of any edge of enclosure.

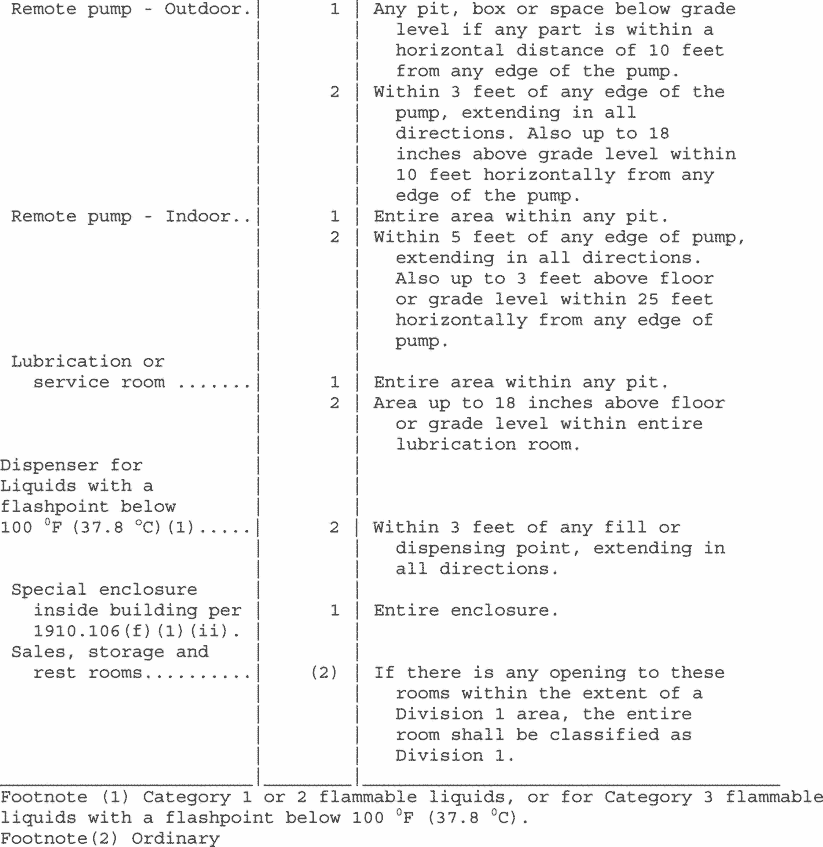

Remote pump - Outdoor. 1 Any pit, box or space below grade level if any part is within a horizontal distance of 10 feet from any edge of the pump. 2 Within 3 feet of any edge of the pump, extending in all directions. Also up to 18 inches above grade level within 10 feet horizontally from any edge of the pump. Remote pump - Indoor. 1 Entire area within any pit. 2 Within 5 feet of any edg of pump, extending in all directions. Also up to 3 feet above floor or grade level within 25 feet horizontally from any edge of pump. Lubrication or service room 1 Entire area within any pit. 2 Area up to 18 inches above floor or grade level within entire lubrication room. Dispenser for Liquids with a flashpoint below 100 °F (37.8 °C)(1) 2 Within 3 feet of any fill or dispensing point, extending in all directions. Special enclosure inside building per 1910.106(f)(1)(ii). 1 Entire enclosure. Sales, storage and rest rooms 2 If there is any opening to these rooms within the extent of a Division 1 area, the entire room shall be classified as Division 1. Footnote (1) Category 1 or 2 flammable liquids, or for Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C). Footnote (2) Ordinary

Electrical equipment —

Application. This paragraph (g)(5) shall apply to areas where Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), are stored or handled. For areas where Category 3 flammable liquids with a flashpoint at or above 100 °F (37.8 °C) or Category 4 flammable liquids are stored or handled the electrical equipment may be installed in accordance with the provisions of subpart S of this part, for ordinary locations.

So far as it applies. Table H–19 shall be used to delineate and classify hazardous areas for the purpose of installation of electrical equipment under normal circumstances. A classified area shall not extend beyond an unpierced wall, roof, or other solid partition.

Heating equipment —

Conformance. Heating equipment shall be installed as provided in paragraphs (g)(6) (ii) through (v) of this section.

Application. Heating equipment may be installed in the conventional manner in an area except as provided in paragraph (g)(6) (iii), (iv), or (v) of this section.

Special room. Heating equipment may be installed in a special room separated from an area classified by Table H–19 by walls having a fire resistance rating of at least 1 hour and without any openings in the walls within 8 feet of the floor into an area classified in Table H–19. This room shall not be used for combustible storage and all air for combustion purposes shall come from outside the building.

Work areas. Heating equipment using gas or oil fuel may be installed in the lubrication, sales, or service room where there is no dispensing or transferring of Category 1 or 2 flammable liquids or 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), provided the bottom of the combustion chamber is at least 18 inches above the floor and the heating equipment is protected from physical damage by vehicles. Heating equipment using gas or oil fuel listed for use in garages may be installed in the lubrication or service room where Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), are dispensed provided the equipment is installed at least 8 feet above the floor.

Electric heat. Electrical heating equipment shall conform to paragraph (g)(5) of this section.

Drainage and waste disposal. Provision shall be made in the area where Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), are dispensed to prevent spilled liquids from flowing into the interior of service station buildings. Such provision may be by grading driveways, raising door sills, or other equally effective means. Crankcase drainings and flammable liquids shall not be dumped into sewers but shall be stored in tanks or drums outside of any building until removed from the premises.

Sources of ignition. In addition to the previous restrictions of this paragraph, the following shall apply: There shall be no smoking or open flames in the areas used for fueling, servicing fuel systems for internal combustion engines, receiving or dispensing of flammable liquids. Conspicuous and legible signs prohibiting smoking shall be posted within sight of the customer being served. The motors of all equipment being fueled shall be shut off during the fueling operation.

Fire control. Each service station shall be provided with at least one fire extinguisher having a minimum approved classification of 6 B, C, located so that an extinguisher, will be within 75 feet of each pump, dispenser, underground fill pipe opening, and lubrication or service room.

Processing plants —

Scope. This paragraph shall apply to those plants or buildings which contain chemical operations such as oxidation, reduction, halogenation, hydrogenation, alkylation, polymerization, and other chemical processes but shall not apply to chemical plants, refineries or distilleries.

Location —

Classification. The location of each processing vessel shall be based upon its flammable liquid capacity.

[Reserved]

Processing building —

Construction.

Drainage.

Ventilation.

Explosion relief. Areas where Category 1 or unstable liquids are processed shall have explosion venting through one or more of the following methods:

Liquid handling —

Storage.

Piping, valves, and fittings.

Transfer.

Equipment.

Tank vehicle and tank car loading and unloading. Tank vehicle and tank car loading or unloading facilities shall be separated from aboveground tanks, warehouses, other plant buildings, or nearest line of adjoining property which may be built upon by a distance of 25 feet for Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 °F (37.8 °C), and 15 feet for Category 3 flammable liquids with a flashpoint at or above 100 °F (37.8 °C) and Category 4 flammable liquids measured from the nearest position of any fill stem. Buildings for pumps or shelters for personnel may be a part of the facility. Operations of the facility shall comply with the appropriate portions of paragraph (f)(3) of this section.

Fire control —

Portable extinguishers. Approved portable fire extinguishers of appropriate size, type, and number shall be provided.

Other controls. Where the special hazards of operation or exposure indicate a need, the following fire control provision shall be provided.

Alarm systems. An approved means for prompt notification of fire to those within the plant and any public fire department available shall be provided. It may be advisable to connect the plant system with the public system where public fire alarm system is available.

Maintenance. All plant fire protection facilities shall be adequately maintained and periodically inspected and tested to make sure they are always in satisfactory operating condition and that they will serve their purpose in time of emergency.

Sources of ignition —

General.

Maintenance and repair.

Electrical.

All electric wiring and equipment shall be installed in accordance with subpart S of this part.

Housekeeping —

General. Maintenance and operating practices shall be in accordance with established procedures which will tend to control leakage and prevent the accidental escape of flammable liquids. Spills shall be cleaned up promptly.

Access. Adequate aisles shall be maintained for unobstructed movement of personnel and so that fire protection equipment can be brought to bear on any part of the processing equipment.

Waste and residues. Combustible waste material and residues in a building or operating area shall be kept to a minimum, stored in closed metal waste cans, and disposed of daily.

Clear zone. Ground area around buildings and operating areas shall be kept free of tall grass, weeds, trash, or other combustible materials.

Refineries, chemical plants, and distilleries —

Storage tanks. Flammable liquids shall be stored in tanks, in containers, or in portable tanks. Tanks shall be installed in accordance with paragraph (b) of this section. Tanks for the storage of flammable liquids in tank farms and in locations other than process areas shall be located in accordance with paragraph (b)(2) (i) and (ii) of this section.

Wharves. Wharves handling flammable liquids shall be in accordance with paragraph (f)(4) of this section.

Fired and unfired pressure vessels —

Fired vessels. Fired pressure vessels shall be constructed in accordance with the Code for Fired Pressure Vessels, Section I of the ASME Boiler and Pressure Vessel Code—1968.

Unfired vessels shall be constructed in accordance with the Code for Unfired Pressure Vessels, Section VIII of the ASME Boiler and Pressure Vessel Code—1968.

Location of process units. Process units shall be located so that they are accessible from at least one side for the purpose of fire control.

Fire control —

Portable equipment. Portable fire extinguishment and control equipment shall be provided in such quantities and types as are needed for the special hazards of operation and storage.

Water supply. Water shall be available in volume and at adequate pressure to supply water hose streams, foam producing equipment, automatic sprinklers, or water spray systems as the need is indicated by the special hazards of operation and storage.

Special equipment. Special extinguishing equipment such as that utilizing foam, inert gas, or dry chemical shall be provided as the need is indicated by the special hazards of operation and storage.

Scope. This section applies to the handling, storage, and use of flammable liquids with a flashpoint at or below 199.4 °F (93 °C) unless otherwise noted. This section does not apply to:

Storage, handling, and use of fuel oil tanks and containers connected with oil burning equipment;

Installations made in accordance with requirements of the following standards that are incorporated by reference as specified in § 1910.6:

National Fire Protection Association Standard for Drycleaning Plants, NFPA No. 32–1970;

National Fire Protection Association Standard for the Manufacture of Organic Coatings, NFPA No. 35–1970;

National Fire Protection Association Standard for Solvent Extraction Plants, NFPA No. 36–1967; or

National Fire Protection Association Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines, NFPA No. 37–1970.

For paragraphs 1910.106(a) to 1910.106(g)(1)(i)(e)(2), see 1910.106 - page 1.

[39 FR 23502, June 27, 1974, as amended at 40 FR 3982, Jan. 27, 1975; 40 FR 23743, June 2, 1975; 43 FR 49746, Oct. 24, 1978; 43 FR 51759, Nov. 7, 1978; 47 FR 39164, Sept. 7, 1982; 51 FR 34560, Sept. 29, 1986; 53 FR 12121, Apr. 12, 1988; 55 FR 32015, Aug. 6, 1990; 61 FR 9227, March 7, 1996; 70 FR 53929, Sept. 13, 2005; 77 FR 17766, March 26, 2012; 81 FR 10490-10491, March 1, 2016]