[Federal Register: October 9, 2008 (Volume 73, Number 197)][Proposed Rules]

[Page 59713-59954]

From the Federal Register Online via GPO Access [wais.access.gpo.gov]

[DOCID:fr09oc08-39]

-----------------------------------------------------------------------

Part II

Department of Labor

-----------------------------------------------------------------------

Occupational Safety and Health Administration

-----------------------------------------------------------------------

29 CFR Part 1926

Cranes and Derricks in Construction; Proposed Rule

-----------------------------------------------------------------------

DEPARTMENT OF LABOR

Occupational Safety and Health Administration

29 CFR Part 1926

[Docket ID-OSHA-2007-0066]

RIN 1218-AC01

Cranes and Derricks in Construction

AGENCY: Occupational Safety and Health Administration (OSHA), Labor.

ACTION: Proposed rule.

-----------------------------------------------------------------------

SUMMARY: OSHA is proposing a rule to protect employees from the hazards

associated with hoisting equipment when used to perform construction

activities. Under this proposed rule, employers would first determine

whether the ground is sufficient to support the anticipated weight of

hoisting equipment and associated loads. The employer then would be

required to assess hazards within the work zone that would affect the

safe operation of hoisting equipment, such as those of power lines and

objects or personnel that would be within the work zone or swing radius

of the hoisting equipment. Finally, the employer would be required to

ensure that the equipment is in safe operating condition via required

inspections and employees in the work zone are trained to recognize

hazards associated with the use of the equipment and any related duties

that they are assigned to perform.

DATES: Submit comments (including comments to the information-

collection (paperwork) determination described under the section titled

"Supplementary Information" of this document), hearing requests, and

other information by December 8, 2008. All submissions must bear a

postmark or provide other evidence of the submission date. (See the

following section titled ADDRESSES for methods you can use in making

submissions.)

ADDRESSES: Comments and hearing requests may be submitted as follows:

Electronic. Comments may be submitted electronically to

http://www.regulations.gov, which is the Federal eRulemaking Portal.

Follow the instructions online for submitting comments.

Facsimile: OSHA allows facsimile transmission of comments

and hearing requests that are 10 pages or fewer in length (including

attachments). Send these documents to the OSHA Docket Office at (202)

693-1648; hard copies of these documents are not required. Instead of

transmitting facsimile copies of attachments that supplement these

documents (e.g., studies, journal articles), commenters may submit

these attachments, in triplicate hard copy, to the OSHA Docket Office,

Technical Data Center, Room N-2625, OSHA, U.S. Department of Labor, 200

Constitution Ave., NW., Washington, DC 20210. These attachments must

clearly identify the sender's name, date, subject, and Docket ID (i.e.,

OSHA-2007-0066) so that the Agency can attach them to the appropriate

document.

Regular mail, express delivery, hand (courier) delivery,

and messenger service: Submit three copies of comments and any

additional material (e.g., studies, journal articles) to the OSHA

Docket Office, Docket ID OSHA-2007-0066 or RIN No. 1218-AC01, Technical

Data Center, Room N-2625, OSHA, Department of Labor, 200 Constitution

Ave., NW., Washington, DC 20210; telephone: (202) 693-2350. (OSHA's TTY

number is (877) 889-5627.) Please contact the OSHA Docket Office for

information about security procedures concerning delivery of materials

by express delivery, hand delivery, and messenger service. The hours of

operation for the OSHA Docket Office are 8:15 a.m. to 4:45 p.m., e.t.

Instructions. All submissions must include the Agency name

and the OSHA Docket ID (i.e., OSHA-2007-0066). Comments and other

material, including any personal information, are placed in the public

docket without revision, and will be available online at http://

www.regulations.gov. Therefore, the Agency cautions commenters about

submitting statements they do not want made available to the public, or

submitting comments that contain personal information (either about

themselves or others) such as social security numbers, birth dates, and

medical data.

Docket. To read or download comments or other material in

the docket, go to http://www.regulations.gov or to the OSHA Docket

Office at the address above. Documents in the docket are listed in the

http://www.regulations.gov index; however, some information (e.g.,

copyrighted material) is not publicly available to read or download

through this Web site. All submissions, including copyrighted material,

are available for inspection and copying at the OSHA Docket Office.

Contact the OSHA Docket Office for assistance in locating docket

submissions.

FOR FURTHER INFORMATION CONTACT: General information and press

inquiries. Contact Ms. Jennifer Ashley, Director, Office of

Communications, OSHA, U.S. Department of Labor, Room N-3647, 200

Constitution Avenue, NW., Washington, DC 20210; telephone (202) 693-

1999 or fax (202) 693-1634.

Technical inquiries. Contact Mr. Garvin Branch,

Directorate of Construction, Room N-3468, OSHA, U.S. Department of

Labor, 200 Constitution Avenue, NW., Washington, DC 20210; telephone

(202) 693-2020 or fax (202) 693-1689.

Copies of this Federal Register notice. Available from the

OSHA Office of Publications, Room N-3101, U.S. Department of Labor, 200

Constitution Avenue, NW., Washington, DC 20210; telephone (202) 693-

1888.

Electronic copies of this notice. Go to OSHA's Web site

(http://www.osha.gov), and select "Federal Register," "Date of

Publication," and then "2008."

Additional information for submitting documents. See

section V.I. ("Public Participation") of this notice.

SUPPLEMENTARY INFORMATION:

I. General

A. Table of Contents

The following Table of Contents identifies the major preamble

sections in this notice and the order in which they are presented:

I. General

A. Table of Contents

B. Hearing

II. Background

A. History

B. The Cranes and Derricks Negotiated Rulemaking Advisory

Committee (C-DAC)

C. Hazards Associated with Cranes and Derricks in Construction

Work

III. The SBREFA Process

IV. Summary and Explanation of the Proposed Standard

V. Procedural Determinations

A. Legal Authority

B. Preliminary Economic Analysis and Initial Regulatory

Flexibility Analysis

C. OMB Review Under the Paperwork Reduction Act of 1995

D. Federalism

E. State-Plan States

F. Unfunded Mandates Reform Act

G. Applicability of Existing Consensus Standards

H. Review of the Proposed Standard by the Advisory Committee for

Construction Safety and Health (ACCSH)

I. Public Participation--Comments and Hearings

B. Hearing

Requests for a hearing should be submitted to the Agency as set

forth above under DATES and ADDRESSES.

II. Background

A. History

The Occupational Safety and Health Act of 1970 (84 Stat. 1590, 29

U.S.C. 651-678) (the OSH Act) authorizes the Secretary of Labor to adopt

safety and health standards to reduce injuries and illnesses in

American workplaces. Pursuant to that authority, the Secretary has

adopted, among others, a set of safety and health standards applicable

to the construction industry, 29 CFR Part 1926. Initially, standards

for the construction industry were adopted under the Construction

Safety Act, 40 U.S.C. 333. Under the Construction Safety Act, those

standards were limited to employers engaged in federally-financed or

federally-assisted construction projects. The Secretary subsequently

adopted them as OSHA standards pursuant to Section 6(a) of the OSH Act,

29 U.S.C. 655(a), which authorized the Secretary to adopt established

federal standards as OSH Act standards within the first two years the

OSH Act was effective (36 FR 25232, Dec. 30, 1971). Subpart N of 29 CFR

part 1926, entitled "Cranes, Derricks, Hoists, Elevators, and

Conveyors," was originally adopted through this process.

The section of subpart N of 29 CFR part 1926 that applies to cranes

and derricks is Sec. 1926.550. That section relies heavily on national

consensus standards that were in effect in 1971, in some cases

incorporating the consensus standards by reference. For example, Sec.

1926.550(b)(2) requires crawler, truck, and locomotive cranes to meet

applicable requirements for design, inspection, construction, testing,

maintenance, and operation prescribed in ANSI B30.5-1968, "Crawler,

Locomotive and Truck Cranes." Similarly, Sec. 1926.550(e) requires

derricks to meet applicable requirements for design, construction,

installation, inspection, testing, maintenance, and operation

prescribed in ANSI B30.6-1969, "Derricks." Since 1971, Sec. 1926.550

has been amended substantively only twice. In 1988, a new paragraph (g)

was added to establish clearly the conditions under which employees on

personnel platforms may be hoisted by cranes and derricks. 53 FR 29116

(Aug. 2, 1988). In 1993, a new paragraph Sec. 1926.550(a)(19) was

added to require that all employees be kept clear of lifted and

suspended loads.

There have been considerable technological changes since the 1971

OSHA standard was issued. For example, hydraulic cranes were rare at

that time but are now prevalent. Although the OSHA standard remains

largely unchanged, the construction industry has updated the consensus

standards on which the OSHA standard is based. For example, the

industry consensus standard for derricks was most recently updated in

2003, and that for crawler, locomotive and truck cranes in 2004.

In recent years, a number of industry stakeholders asked the Agency

to update Subpart N's cranes and derrick requirements. They were

concerned that accidents involving cranes and derricks continued to be

a significant cause of fatal and other serious injuries on construction

sites and believed that an updated standard was needed to address the

causes of these accidents and to reduce their numbers. They emphasized

that the considerable changes in both work processes and technology

have made much of Subpart N obsolete.

In response to these requests, in 1998 OSHA's Advisory Committee

for Construction Safety and Health (ACCSH) established a workgroup to

develop recommended changes to the Subpart N requirements for cranes

and derricks. The workgroup developed recommendations on some issues

and submitted them to the full committee in a draft workgroup report.

(OSHA-2007-0066-0020). In December 1999, ACCSH recommended to OSHA that

the agency consider using a negotiated rulemaking process as the

mechanism to update Subpart N (ACCSH 1999-4, Ex. 100x, p. 112).

B. The Cranes and Derricks Negotiated Rulemaking Advisory Committee (C-

DAC)

In July 2002, OSHA announced its intent to use negotiated

rulemaking under the Negotiated Rulemaking Act (NRA), 5 U.S.C. 561 et

seq., to revise the cranes and derricks standard. The Agency made this

decision in light of the stakeholder interest in updating Subpart N,

the constructive discussions and work of the ACCSH workgroup, ACCSH's

recommendation, a positive assessment of the criteria listed in the NRA

(5 U.S.C. 563(a)) for the use of negotiated rulemaking, and the

Department of Labor's policy on negotiated rulemaking (See "Notice of

Policy on Use of Negotiated Rulemaking Procedures by Agencies of the

Department of Labor," 57 FR 61925 (Dec. 29, 1992)). The Agency issued

a notice of intent to use negotiated rulemaking for this project and

establish the Cranes and Derricks Negotiated Rulemaking Advisory

Committee ("C-DAC" or "the Committee") (67 FR 46612, July 16,

2002).

Negotiated rulemaking is a process by which a proposed rule is

developed by a committee comprised of members who represent the

interests that will be significantly affected by the rule. Section 562

of the NRA defines "interest" as follows:

"[I]nterest" means, with respect to an issue or matter,

multiple parties which have a similar point of view or which are

likely to be affected in a similar manner.

By bringing different viewpoints to the table and sharing views,

the members of the negotiated rulemaking committee learn the reasons

for different positions on the issues as well as the practical effect

of various approaches. Each member of the committee participates in

resolving the interests and concerns of other members. Negotiation

allows interested parties, including members who represent the

interests of employers who will be subject to the rule and the

employees who stand to benefit from the safer workplaces the rule will

produce, to become involved at an earlier stage of the rulemaking

process. As a result, the rule that OSHA proposes will have already

received close scrutiny by affected parties at the pre-proposal stage.

The goal of the negotiated rulemaking process is to develop a

proposed rule that represents a consensus of all the interests. The NRA

defines consensus as unanimous concurrence among the interests

represented on a negotiated rulemaking committee unless the committee

itself unanimously agrees to use a different definition of consensus.

As discussed below, C-DAC agreed by unanimous vote to a different

definition: a consensus was reached on an issue when not more than two

non-federal members dissented on that issue.

In the July 2002 notice of intent to establish a negotiated

rulemaking committee referred to above, the Agency listed key issues

that OSHA expected the negotiations to address and the interests that

OSHA had tentatively identified as being significantly affected by the

rulemaking. Those interests were:

--Crane and derrick manufacturers, suppliers, and distributors.

--Companies that repair and maintain cranes and derricks.

--Crane and derrick leasing companies.

--Owners of cranes and derricks.

--Construction companies that use cranes and derricks.

--General contractors.

--Labor organizations representing construction employees who operate

cranes and derricks.

--Labor organizations representing construction employees who work in

conjunction with cranes and derricks.

--Owners of electric power distribution lines.

--Civil, structural and architectural engineering firms and engineering

consultants involved with the use of cranes and derricks in

construction.

--Training organizations.

--Crane and derrick operator testing organizations.

--Insurance and safety organizations, and public interest groups.

--Trade associations.

--Government entities involved with construction safety and with

construction operations involving cranes and derricks.

OSHA asked for public comment on whether interests other than those

listed would be significantly affected by a new rule. It also solicited

requests for membership on the committee. OSHA urged interested parties

to communicate with others who shared similar interests and to begin

organizing coalitions to support those interests in order to identify

individuals for nomination to the committee.

The Agency noted that the need to limit the committee's membership

to a number that could conduct effective negotiations might mean that

not all interests could be represented on the committee itself.

However, OSHA further noted that interested persons had means other

than committee membership available to participate in the committee's

deliberations, including attending committee meetings and addressing

the committee, providing written comments to the committee, and

participating in committee workgroups. 67 FR at 46615.

In response to its request for public input, the Agency received

broad support for using negotiated rulemaking and 55 nominations for

committee membership. To keep membership to a reasonable size, OSHA

tentatively listed 20 potential committee members and asked for public

comment on that proposed list. 68 FR 9036 (Feb. 27, 2003). In response

to the comments, OSHA added three members to the committee--individuals

from the mobile crane manufacturing industry, the Specialized Carriers

& Rigging Association, and the outdoor advertising industry. 68 FR

39879 (July 3, 2003).

The members of the Committee, the organizations and interests they

represent, and a summary of their qualifications at the time the

Committee was formed are in Table 1 as follows:

Table 1--The Qualifications of C-DAC Panel Members

------------------------------------------------------------------------

------------------------------------------------------------------------

Stephen Brown, International Union of

Operating Engineers (labor).

Title.................................. Director of Construction

Training, International Union

of Operating Engineers.

Organizations/Interests represented.... Organized construction

employees who operate cranes

and derricks, and work with

such equipment.

Experience............................. Worked in numerous positions in

the construction industry over

28 years, including Equipment

Operator, Mechanic, and

Training Director.

Michael Brunet, Manitowoc Cranes, Inc.

(manufacturers and suppliers).

Title.................................. Director of Product Support for

Manitowoc Cranes.

Organizations/Interests represented.... Crane manufacturers, suppliers,

and distributors.

Experience............................. Extensive engineering

experience in crane

engineering; participated in

development of SAE and ISO

standards for cranes.

Stephen P. Charman, Viacom Outdoor,

Inc. (employer users).

Title.................................. Vice President (New York) of

Viacom Outdoor Group.

Organizations/Interests represented.... Billboard construction.

Experience............................. Over 43 years' experience with

the construction industry,

including specialized rigging.

Joseph Collins, Zachry Construction

Corporation (employer users).

Title.................................. Crane Fleet Manager.

Organizations/Interests represented.... Highway/Railroad Construction.

Experience............................. Over 30 years' experience with

the construction industry in a

variety of positions including

crane operator, mechanic, and

rigger.

Noah Connell, U.S. Department of Labor,

Occupational Safety and Health

Administration (government).

Title.................................. Director, Office of

Construction Standards and

Guidance.

Organization/Interests represented..... Government.

Experience............................. 22 years' experience with

government programs.

Peter Juhren, Morrow Equipment Company,

L.L.C. (manufacturers and suppliers).

Title.................................. National Service Manager.

Organization/Interests represented..... Tower crane distributor/

manufacturer.

Experience............................. 22 years' experience with

Morrow Equipment Company,

L.L.C.

Bernie McGrew, Link-Belt Construction

Equipment Corp. (manufacturers and

suppliers).

Title.................................. Manager for Crane Testing,

Product Safety, Metal Labs and

Technical Computing.

Organization/Interests represented..... Mobile crane manufacturers.

Experience............................. Extensive engineering

experience in crane

engineering.

Larry Means, Wire Rope Technical Board

(manufacturers and suppliers).

Title.................................. Rope Engineer.

Organization/Interests represented..... Wire rope manufacturing

industry.

Experience............................. 36 years' wire rope engineering

experience.

Frank Migliaccio, International

Association of Bridge, Structural,

Ornamental and Reinforcing Iron

Workers (labor organization).

Title.................................. Executive Director for Safety

and Health.

Organization/Interests Represented..... Organized construction

employees who operate cranes

and derricks, and work with

such equipment.

Experience............................. 31 years' experience in the

ironworking industry,

including ten years as

Director of Safety and Health

Training for the Ironworker's

National Fund.

Brian Murphy, Sundt Corporation

(employer users).

Title.................................. Vice President and Safety

Director.

Organization/Interests Represented..... General contractors/crane

owners/users.

Experience............................. Over 35 years' experience in

the construction industry,

most of them with Sundt.

George R. "Chip" Pocock, C.P. Buckner

Steel Erection (employer users).

Title.................................. Safety and Risk Manager.

Organization/Interests Represented..... Steel Erection crane user/

employers.

Experience............................. Over 22 years' experience in

the construction/steel

erection industry.

David Ritchie, St. Paul Companies

(trainer and operator testing).

Title.................................. Crane and Rigging Specialist.

Organization/Interests Represented..... Employee Training/Evaluation.

Experience............................. Over 31 years' experience in

the construction industry.

Emmett Russell, International Union of

Operating Engineers (labor).

Title.................................. Director of Safety and Health.

Organization/Interests Represented..... Organized construction

employees who operate cranes

and derricks, and work with

such equipment.

Experience............................. Over 32 years' experience in

the crane/construction

industry, including ten years

in the field as well as over

20 years with IUOE.

Dale Shoemaker, Carpenters

International Training Center (labor).

Organization/Interests Represented..... Labor organizations

representing construction

employees who operate cranes

and derricks and who work in

conjunction with cranes and

derricks.

Experience............................. Became a crane operator in

1973; served as a rigging

trainer for labor

organizations since 1986.

William Smith, Maxim Crane Works

(lessors/maintenance).

Title.................................. Corporate Safety/Labor

Relations Manager.

Organization/Interests Represented..... Crane/Derrick repair and

maintenance companies.

Experience............................. 24 years' experience in the

crane, rigging, and

construction industry, both

public and private sectors.

Craig Steele, Schuck & Sons

Construction Company, Inc. (employer

users).

Title.................................. President and CEO.

Organization/Interests Represented..... Employers/users engaged in

residential construction.

Experience............................. 30 years' experience in the

construction industry with

Schuck & Sons Construction

Company, Inc.

Darlaine Taylor, Century Steel

Erectors, Inc. (employer users).

Title.................................. Vice President.

Organization/Interests Represented..... Steel Erection/Leased Crane

Users.

Experience............................. 19 years with Century Steel

Erectors, over 12 years in the

construction safety field.

Wallace Vega III, Entergy Corp. (power

line owners).

Organization/Interests Represented..... Power line owners.

Experience............................. 35 years' experience in the

power line industry.

William J. "Doc" Weaver, National

Electrical Contractors Association

(employer users).

Organization/Interests Represented..... Electrical contractors engaged

in power line construction.

Experience............................. Over 53 years' electrical

construction experience, 37 of

which is spent in management

positions.

Robert Weiss, Cranes, Inc. and A.J.

McNulty & Company, Inc. (employer

users).

Title.................................. Vice President and Project

Manager for Safety

(respectively).

Organization/Interests Represented..... Employers/users engaged in

precast concrete erection.

Experience............................. 20 years' experience in the

precast and steel erection

industry.

Doug Williams, C.P. Buckner Steel

Erection (employer users).

Title.................................. President.

Organization/Interests Represented..... Buckner Heavy Lift Cranes.

Experience............................. 32 years' experience in the

construction industry.

Stephen Wiltshire, Sports and Public

Assembly Group, Turner Construction

Corp. (employer users).

Title.................................. National Safety Director.

Organization/Interests Represented..... Employer/users of owned and

leased cranes.

Experience............................. 28 years' experience in

construction safety.

Charles Yorio, Acordia (Wells Fargo)

(insurance).

Title.................................. Assistant Vice President.

Organization/Interests Represented..... Insurance.

Experience............................. 17 years' experience in loss

prevention and regulatory

compliance.

------------------------------------------------------------------------

C-DAC was chaired by a facilitator, Susan L. Podziba of Susan

Podziba & Associates, a firm engaged in public policy mediation and

consensus building. Ms. Podziba's role was to facilitate the

negotiations by:

(1) Chairing the Committee's meetings in an impartial manner;

(2) impartially assisting the members of the committee in

conducting discussions and negotiations; and

(3) supervising the taking of minutes and keeping of records and

other relevant responsibilities, including the drafting of meeting

summaries after each meeting to be reviewed and approved by C-DAC

members.

C-DAC first met from July 30 to August 1, 2003. Before addressing

substantive issues, the Committee developed ground rules (formally

approved on September 26, 2003) that would guide its deliberations.

(OSHA-S030-2006-0663-0373). In addition to procedural matters, the

ground rules addressed the nature and consequences of the Committee's

decision-making. C-DAC agreed that it would make every effort to reach

unanimous agreement on all issues. However, if the facilitator

determined that unanimous consent could not be achieved, the Committee

would consider consensus to be reached when not more than two non-

federal members (i.e., members other than the OSHA member) dissented.

Under this definition, if OSHA dissented, there would be no consensus.

This definition of consensus reflects the non-federal members' view

that Agency support of the Committee's work was essential. The non-

federal members believed that, if OSHA dissented, there would be little

likelihood that the Committee's work product would eventually be

reflected in the final rule. These members wanted to ensure that

concerns of the Agency that would prompt it to dissent were instead

resolved in the negotiating process.

Under this ground rule, if C-DAC reached a final consensus

agreement on some or all issues, OSHA would use the consensus-based

language on those issues for which agreement was reached as its

proposed standard, and C-DAC members would refrain from providing

formal written negative comment on those issues in response to the

proposed rule.

The ground rules provide that OSHA may only depart from this aspect

of the agreement by either reopening the negotiated rulemaking process

or providing to the C-DAC members a detailed statement of the reasons

for altering the consensus-based language sufficiently far in advance

of publication that the C-DAC members could express their concerns to

OSHA. The Committee members could also provide negative or positive

public comment in response to those changes. (OSHA-S030-2006-0663-

0373).

A tentative list of issues for the Committee to address was

published along with the final list of Committee members (68 FR at

39879-90). At its initial meeting, the Committee reviewed and revised

the issue list, adding several issues. (OSHA-S030-2006-0663-0372). The

Committee met 11 times between July 30, 2003 and July 9, 2004. As the

meetings progressed, the Committee reached consensus agreement on

various issues and, at the final meeting, reached consensus agreement

on all outstanding issues. The Committee's work product, which is the

Committee's recommended regulatory text for the proposed rule, is

referred to here as the C-DAC Consensus Document. (OSHA-S030-2006-0663-

0639). On October 12, 2006, ACCSH adopted a resolution supporting the

C-DAC Consensus Document and recommending that OSHA use it as the basis

for a proposed standard. (ACCSH 2006-1, Ex. 101x, pp. 248-49).

As noted earlier, OSHA's assent was needed for C-DAC to reach

consensus agreement on an issue. Thus, the fact that the Committee

reached consensus agreement on all issues means that this proposal

reflects OSHA's agreement with the Consensus Document. In the

discussion of the various sections of the proposal below, when the

Committee's views or conclusions are stated, OSHA agrees with those

views or conclusions unless otherwise noted.

In reviewing the Consensus Document to draft this proposed rule,

OSHA identified certain problems in the Consensus Document. These range

from misnumbering and other typographical/technical errors to

provisions that appear to be inconsistent with the Committee's intent

or that are worded in a manner that requires clarification. This

proposed rule deviates from the Consensus Document where changes were

clearly needed to reflect the Committee's intent, or to correct

typographical/technical errors. With respect to substantive changes,

the Agency has identified and explained them in the portions of this

preamble that address the affected provisions.

There are instances where it appears to the Agency that other

changes may be needed for several reasons: To conform to the

Committee's intent; where the precise form of a change needed to

conform to that intent is not clear; or where an aspect of a

significant issue appears not to have been considered by C-DAC. In each

such instance OSHA has retained the regulatory language used in the

Consensus Document but asks for public comment on them.

Numerous Committee members had vast and varied experience in cranes

and derricks in construction, which gave them a wealth of knowledge in

the causes of accidents and safety issues involving such equipment. In

addition, other members had substantial knowledge and experience in

other types of subject areas that also related to crane and derrick

safety. This is reflected in the summary of their qualifications (see

list above).

The members used this knowledge to identify issues that required

particular attention and to devise regulatory language that would

address the causes of such accidents. Their extensive practical

experience in the construction industry and the other industries

represented on the Committee helped them to design improvements to the

current Subpart N requirements that would be practical and workable.

This preamble describes the proposed standard and the Committee's

reasons for resolving the various issues in the manner it did.

In examining the causes of crane accidents and devising ways to

reduce them, the Committee concluded that incorrect operation was a

factor in many accidents. Operating a crane is a complex job requiring

skill and knowledge. To operate a crane safely requires a thorough

knowledge of the equipment and controls and a complete understanding of

the factors that can affect the safety of its operation. The Committee

believed that it was essential to address the issue of operator

qualification so that accidents resulting from incorrect operation

would be reduced.

C-DAC spent considerable time and effort determining how the

proposed rule could best ensure that equipment operators are well

qualified. C-DAC decided that it was necessary for crane operators to

be certified or qualified through a formal process to ensure that they

possessed the degree of knowledge necessary to operate their equipment

safely. The Committee's reasoning and the details of the qualification/

certification process are discussed below in connection with Sec.

1926.1427, Operator Qualification and Certification.

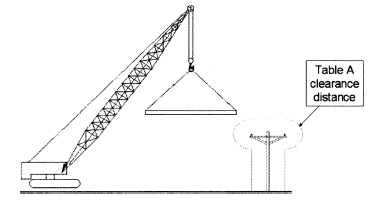

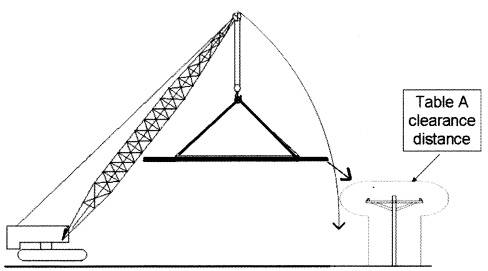

Another cause of numerous fatal and serious accidents that C-DAC

addressed was equipment making electrical contact with power lines.

Although Subpart N currently addresses this issue by requiring

equipment to maintain a minimum distance from power lines that depends

on the voltage of the line, the Committee identified reasons why the

current standard was not preventing the many accidents that continue to

occur. The Committee concluded that simply requiring a minimum

clearance distance was not sufficient to eliminate the human error that

led to most instances of power line contact and that additional requirements

that would help employers identify potential power line hazards and

systematic procedures to protect against those hazards were needed to

prevent power line contact. See the discussion below under Sec. Sec.

1926.1407-1411, which deal with the various aspects of power line

safety.

As noted above, OSHA's current standard on cranes and derricks, 29

CFR 1926.550, incorporates numerous national consensus standards by

reference. The Committee reviewed the most recent versions of these

consensus standards. For some issues, the Committee determined that a

different approach was warranted (such as in the case of protections

against power lines and operator qualification/certification). In many

other instances the Committee determined that concepts in the consensus

standards were appropriate but that different wording was needed to

improve clarity and enforceability, or to be more readable within the

structure of the proposed rule.

Where the Committee incorporated consensus standards by reference,

it agreed with the concepts, found the structure and wording

appropriate, and determined that the incorporation of the provisions

would not detract from its goal of producing a readable document. In

addition, to avoid encumbering the text with too much length and

technical detail that would hinder readability, C-DAC decided to

incorporate by reference certain requirements from consensus standards

where those requirements addressed highly technical topics, such as

welding criteria.

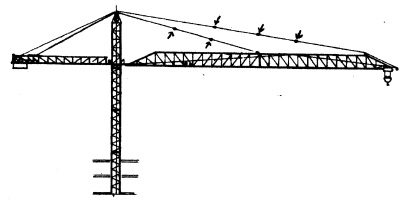

C-DAC also determined that some categories of equipment needed to

be addressed differently than others. The proposed standard contains

general requirements in Sec. Sec. 1926.1402-1434 that are appropriate

for most types of equipment and workplaces but which contain certain

specific exclusions. Sections 1926.1435-1441 each address a specific

type of equipment, such as Sec. 1926.1435, Tower cranes. Those

sections tailor the requirements of the proposed standard to

accommodate the unique characteristics of that equipment. They state

which of the general provisions in Sec. Sec. 1926.1402-1434 apply to

that type of equipment and which do not. They also include requirements

specific to that type of equipment either (as specified) as a

substitute for, or in addition to, the general provisions in Sec. Sec.

1926.1402-1434. In this way, C-DAC ensured that each type of equipment

would be subject to requirements appropriate for that equipment.

In drafting some of the provisions in this proposal, the Committee

recognized that OSHA would be requiring cranes and derricks to be

equipped with operational aids that have not been mandatory in the

past. For some types of these aids, the Committee believed it would be

impractical to require that cranes and derricks be retrofitted with the

devices. In determining whether to propose that such requirements be

prospective only, the Committee considered the degree of importance of

the device to safety, whether the devices are required under industry

consensus standards and, if so, the date they were first required under

such standards. Recognizing that manufacturers generally follow

industry consensus standards, C-DAC drafted these provisions to require

equipment manufactured after the date an operational aid was required

by an industry consensus standard to be equipped with the device.

In situations where no industry consensus standard required that

cranes or derricks be equipped with a certain operational aid or fall

protection device, the Committee decided to allow sufficient lead time

for manufacturers to install the aids and devices. The Committee

proposed to require some aids and devices on equipment manufactured one

year after the effective date of this standard. In other cases, the

Committee specified that the aids and devices would be required on

equipment manufactured after January 1, 2008.

It is now evident that the standard will not be finalized by that

date and that keying requirements to that date will not afford

employers the lead time intended by the Committee. To conform this

proposed standard to the Committee's intent, and to ensure that

industry has sufficient lead time to equip cranes and derricks with the

required aids and devices, OSHA is substituting "more than one year

after the effective date of this standard" for "January 1, 2008"

wherever that date appears in the Committee's draft.

C. Hazards Associated With Cranes and Derricks in Construction Work

OSHA estimates that 89 crane-related fatalities occur per year in

construction work. The causes of crane-related fatalities were recently

analyzed by Beavers, et al. J.E. Beavers, J.R. Moore, R. Rinehart, and

W.R. Schriver, "Crane-Related Fatalities in the Construction

Industry," 132 Journal of Construction Engineering and Management 901

(Sept. 2006) (OSHA-2007-0066-0012). The authors searched OSHA's

Integrated Management Information System (IMIS) database for all fatal

accidents for 1997-2003 investigated by OSHA involving cranes in the

construction industry. By searching the database for cases using the

key words "crane," "derrick," or "boom," they identified 381 IMIS

files for the covered years in the federal program states, which

include states with about 57% of all workers throughout the country.

The authors requested the case files from OSHA so that they could

confirm that a crane or derrick was involved in the fatality. Of the

335 case files that OSHA provided, the authors identified 125

(involving 127 fatalities) as being crane or derrick related. From

these files, they determined that the percentages of fatalities caused

by various types of incident are in Table 2 as follows:

Table 2--The Causes of Fatalities during the Performance of Hoisting

Activities

------------------------------------------------------------------------

Percent

------------------------------------------------------------------------

Struck by load (other than failure of boom/cable)............ 32

Electrocution................................................ 27

Crushed during assembly/disassembly.......................... 21

Failure of boom/cable........................................ 12

Crane tip-over............................................... 11

Struck by cab/counterweight.................................. 3

Falls........................................................ 2

------------------------------------------------------------------------

A study by Suruda et al. examined the causes of crane-related

deaths for the 1984-1994 period. A. Suruda, M. Egger, & D. Liu,

"Crane-Related Deaths in the U.S. Construction Industry, 1984-94,"

The Center to Protect Workers' Rights (Oct. 1997) (OSHA-2007-0066-

0013). The authors examined OSHA IMIS data to identify the number of

fatal accidents involving cranes and determine their causes. For the

years in question, they found 479 accidents involving 502 fatalities.

In the worst year, 1990, 70 deaths occurred.

The authors noted some limitations in the data they examined: Data

for California, Michigan, and Washington state were not available for

1984-1989; the proportion of fatal accidents that OSHA and the states

that enforce their own state plans investigate is unknown; and some of

the investigation reports were not sufficiently detailed to allow the

cause of the accident or the type of crane involved to be determined.

The Suruda study determined that the number and the percentage of

fatalities from various causes are in Table 3 as follows:

Table 3--The Causes of Crane Incidents

------------------------------------------------------------------------

------------------------------------------------------------------------

Electrocution.............................................. 198 (39%)

Crane assembly/disassembly................................. 58 (12%)

Boom buckling/collapse..................................... 41 (8%)

Crane upset/overturn....................................... 37 (7%)

Rigging failure............................................ 36 (7%)

Overloading................................................ 22 (4%)

Struck by moving load...................................... 22 (4%)

Accidents related to manlifts.............................. 21 (4%)

Working within swing radius of counterweight............... 17 (3%)

Two-blocking............................................... 11 (2%)

Hoist limitations.......................................... 7 (1%)

Other causes............................................... 32 (6%)

------------------------------------------------------------------------

The proposed standard addresses the major causes of the equipment

related fatalities identified in the Beavers and Suruda studies. The

following is a brief synopsis of the sections in this proposed standard

that address them; each proposed section is explained in detail later

in this preamble.

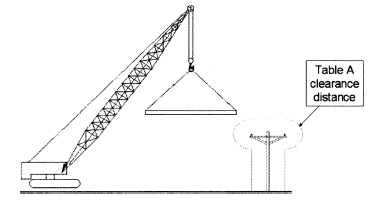

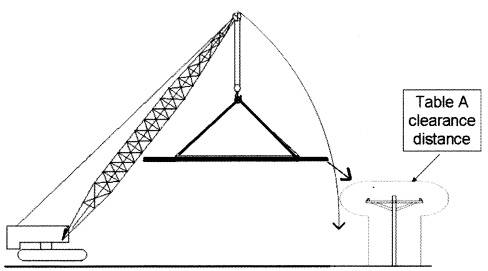

The electrocution hazard is addressed by proposed Sec. Sec.

1926.1407-1411, which deal with various aspects of power line safety.

These sections contain requirements designed to prevent equipment from

contacting energized power lines. The proposed rule delineates

systematic, reliable procedures and methods that must be used to

prevent a safe clearance distance from being breached. If maintaining

the safe clearance distance is infeasible, additional protections would

be required, including grounding the equipment, covering the line with

an insulating sleeve, and using insulating links and nonconductive tag

lines.

These procedures and methods are supplemented by requirements for

training the operator and crew in power line safety and the requirement

for operator qualification and certification in proposed Sec.

1926.1427. C-DAC concluded that compliance with these training and

certification requirements will not only reduce the frequency of power

line contact but will give the workers the knowledge they need to help

avoid injury in the event such contact does occur.

Fatalities that involve employees being struck or crushed during

assembly/disassembly are addressed in proposed Sec. Sec. 1926.1403-

1406. These sections require certain specific safe practice procedures

to be followed and for the employer to address a list of specific

hazards. Also, assembly/disassembly must be supervised by an individual

who is well qualified to see that these requirements are properly

implemented.

As the studies show and the Committee's experience confirms, many

disassembly accidents occur when sections of lattice booms unexpectedly

move and strike or crush an employee who is disassembling the boom. The

proposal addresses this scenario in proposed Sec. 1926.1404(f) by

prohibiting employees from being under the boom when pins are removed

unless special precautions are taken to protect against boom movement.

Accidents resulting from boom or cable failure are addressed in a

number of provisions. For example, the proposed standard includes

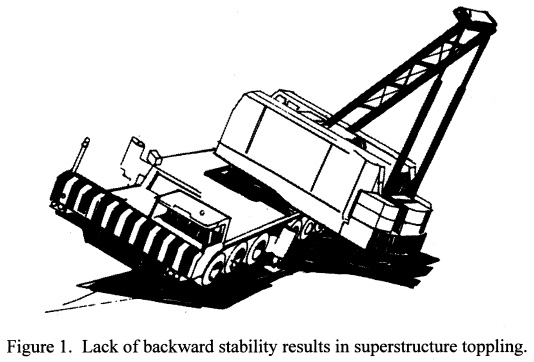

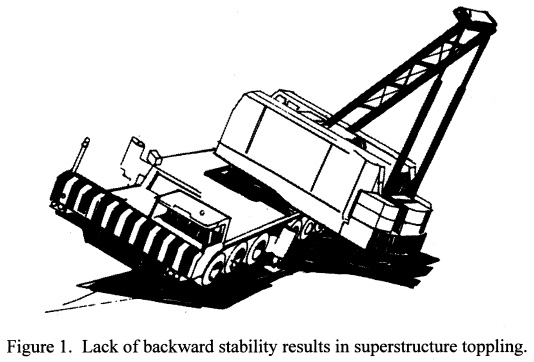

requirements for: Proper assembly procedures (proposed Sec.

1926.1403); boom stops to prevent booms from being raised too far and

toppling over backwards (proposed Sec. 1926.1415, Safety devices); a

boom hoist limiting device to prevent excessive boom travel, and an

anti-two-block device, which prevents overloading the boom from two-

blocking (proposed Sec. 1926.1416, Operational aids). Also, the

inspection requirements (proposed Sec. 1926.1412) are designed so that

a structural deficiency in a boom will be detected and addressed before

an accident occurs. Cable failure will be avoided by compliance with

proposed sections such as Sec. 1926.1413, Wire rope--inspection, Sec.

1926.1414, Wire rope--selection and installation criteria, and the

provision in proposed Sec. 1926.1416 requiring two-block protection.

Crane tip-over is caused by factors such as overloading, improper

use of outriggers and insufficient ground conditions. Proposed Sec.

1926.1417, Operations, includes provisions designed to prevent

overloading. That section prohibits the equipment from being operated

in excess of its rated capacity and includes procedures for ensuring

that the weight of the load is reliably determined and within the

equipment's rated capacity. Proposed Sec. 1926.1404(q) has

requirements for outrigger use designed to ensure that outriggers are

properly set when they are needed to provide stability when a load is

lifted. Proposed Sec. 1926.1402 has requirements designed to ensure

sufficient ground conditions.

The provisions on training and operator qualification and

certification will also prevent this type of accident by ensuring that

the operator is sufficiently knowledgeable and skilled to recognize

situations when the crane may be overloaded and to either require that

the situation be corrected or refuse to proceed in accordance with

proposed Sec. 1926.1418, Authority to stop operation.

Fatalities that result from workers being struck by the cab or

counterweights will be avoided by compliance with proposed Sec.

1926.1424, Work area control. That section would require that employees

who must work near equipment with a rotating superstructure be trained

in the hazards involved, that employers mark or barricade the area

within the area covered by the rotating superstructure, and that the

operator be alerted whenever an employee must enter that area and not

rotate the superstructure until the area is clear. Protection against

being struck by a counterweight during assembly/disassembly is provided

by proposed Sec. 1926.1404(h)(9), which would require the assembly/

disassembly supervisor to address this hazard and take steps when

necessary to protect workers against that danger.

The proposal addresses a number of types of equipment failure that

can result in the load striking a worker. Such accidents are directly

addressed by proposed Sec. 1926.1425, Keeping clear of the load, and

Sec. 1926.1426, Free fall/controlled load lowering. In addition,

improved requirements in proposed Sec. Sec. 1926.1419-1422 for

signaling will help avoid load struck-by accidents caused by

miscommunication.

Improper operation, including, for example, the failure to

understand and compensate for the effects of factors such as dynamic

loading, can also cause employees to be struck by a load. Such

incidents will be reduced by compliance with proposed Sec. 1926.1427,

Operator qualification and certification and proposed Sec. 1926.1430,

Training. Other provisions, such as those for safety devices and

operational aids (proposed Sec. 1926.1415 and Sec. 1926.1416), and

the requirement for periodic inspections in proposed Sec. 1926.1412,

will also reduce the number of this type of accident.

Protection against falling from equipment is addressed by proposed

Sec. 1926.1423, Fall protection. That section would require new

equipment to provide safe access to the operator work station by the

use of devices such as steps, handholds, and grabrails. Certain new

lattice boom equipment would have to be equipped with boom walkways.

There are also fall protection provisions tailored to assembly and

disassembly work and to other work. Proposed Sec. 1926.1431, Hoisting

personnel, addresses fall protection when employees are being hoisted.

OSHA has investigated numerous equipment accidents that have

resulted in fatalities from the causes listed in the Beavers and Suruda

studies. Below is a discussion of examples from OSHA's IMIS accident

investigation reports from recent years that illustrate some of the

types of accidents that occur when using the types of equipment covered

by this proposed standard and the ways that this proposed standard would

prevent such incidents. These examples illustrate the limitations of

the current standard and highlight the need for a revised standard that

will address the causes of the equipment accidents that continue to

kill and injure construction workers.

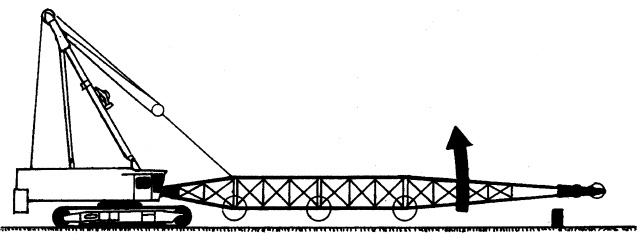

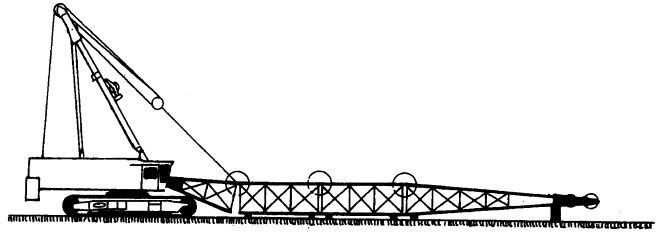

1. February 16, 2004: 4 fatalities, 4 injuries. A launching gantry

collapsed and fatally injured 4 workers and sent 4 other workers to the

hospital. The launching gantry was being used to erect pre-cast

concrete segments span by span. The manufacturer required that the rear

legs and front legs be properly anchored to resist longitudinal and

lateral forces that act on the launching gantry. The legs of the

launching gantry were not properly anchored. (OSHA-2007-0066-0017).

OSHA believes that this type of accident would be prevented by

compliance with the provisions of this proposed standard for assembling

equipment. Proposed Sec. 1403 requires that equipment be assembled in

compliance with manufacturer procedures or with alternative employer

procedures (see proposed Sec. 1406) designed, among other things, to

prevent the equipment from collapsing. In addition, under proposed

Sec. 1404, assembly must be conducted under the supervision of a

person who understands the hazards associated with an improperly

assembled crane and is well-qualified to understand and comply with the

proper assembly procedures.

2. January 30, 2006. 1 fatality. An employee was crushed by the

lower end section of the lattice boom on a truck mounted crane while

working from a position underneath the boom to remove the 2nd lower

pin. When the 2nd lower pin was removed the unsecured/uncribbed boom

fell on the employee. (OSHA-2007-0066-0017.1)

Proposed Sec. 1926.1404(f) would prevent this type of accident by

generally prohibiting employees from being under the boom when pins are

removed. In situations where site constraints require an employee to be

under the boom when pins are removed, the employer must implement other

procedures, such as ensuring that the boom sections are adequately

supported, to prevent the sections from falling onto the employee.

3. July 23, 2001: 1 fatality. Employee failed to extend the

outriggers before he extended the boom of a service truck crane to lift

up some pipes. As he extended his boom, the crane tipped over on its

side and an employee was struck on the head by the hook block as he

stood near the rear of the truck. (OSHA-2007-0066-0017.10)

This type of accident would be prevented by compliance with

proposed Sec. 1926.1404(q), which contains several provisions designed

to ensure that outriggers are deployed properly before lifting a load.

In addition, the operator qualification and certification requirement

of proposed Sec. 1926.1427, which is intended to ensure that operators

understand and follow the safety requirements for the equipment they

are operating, would help prevent this type of accident.

4. March 8, 1999. 1 fatality. Some employees were using a mobile

crane to maneuver a load of steel joists. The crane contacted a 7,200-

volt overhead power line, electrocuting an employee who was signaling

and guiding the load. The crane operator jumped clear and was not

injured. (OSHA-2007-0066-0017.11)

Section 1926.1408 includes provisions that would prevent this type

of accident. First, it would require the use of "encroachment

prevention" measures designed to prevent the crane from breaching a

safe clearance distance from the power line. Second, if tag lines are

used to guide the load, they would have to be non-conductive. Third, if

maintaining the normal clearance distance were infeasible, a number of

additional measures would have to be used. One of those additional

measures is the use of an insulating link between the end of the load

line and the load.

These measures would protect the employee guiding the load in

several ways, including the following: First, they would reduce the

chance that the crane would come into electrical contact with the power

line. Second, if the employee were using a tag line to guide the load,

it would have to be non-conductive, which would protect the employee if

the load became energized.

If the crane were intentionally operated closer than the normal

clearance distance, and the employer complied with the additional

protective measures required in that circumstance, an insulating link

would be in place. In such a case, even if there was a failure of the

encroachment prevention measures and electrical contact resulted, the

insulating link would prevent the load from becoming energized and

prevent the employee guiding the load from being electrocuted.

5. August 21, 2003. 3 fatalities. A crane operator and two co-

workers were electrocuted when a truck crane's elevated boom contacted

a 7,200 Volt uninsulated primary conductor 31 feet from the ground.

When the operator stepped from the cab of the truck he created a

conduction pathway to the ground through his right hand and right foot,

causing him to be electrocuted. A co-worker attempted to revive the

incapacitated crane operator with cardio-pulmonary resuscitation

("CPR") while a third co-worker contacted 911 and returned to the

incident location. When the third co-worker simultaneously touched the

energized truck crane and the back of his co-worker performing CPR, the

resulting pathway created a conduction pathway through the workers,

electrocuting them all. (OSHA-2007-0066-0017.12).

This type of accident would be avoided by compliance with the

proposed rule. First, as explained in the previous electrocution

accident examples, proposed Sec. 1926.1408 is designed to ensure that

a minimum safe distance from the power line is maintained, which would

prevent the equipment from becoming energized. Also, when working

closer than the normal minimum clearance distance, the crane would have

to be grounded; that would reduce the chance of an electrical pathway

through the employees in this type of scenario.

In addition, proposed Sec. 1926.1408(g) would require the operator

to be trained to remain inside the cab unless there is imminent danger

of fire or explosion. The operator must also be trained in the danger

of simultaneously touching the equipment and the ground, as he did in

this case, and in the safest means of evacuating the equipment. The

crane's remaining crew must be trained to avoid approaching or touching

the equipment. The required training would be reinforced by the

electrocution warnings that must be posted in the cab and on the

outside of the equipment.

6. September 28, 1999: 1 fatality. A 19-year old electrical

instrument helper was at a construction site that was on a

manufacturing company's property. That morning a contractor had

positioned a 50-ton hydraulic crane in an open area that consisted of

compacted fill material. This was the only location that the crane

could be situated because the receiving area for the equipment was very

close to the property border. The crane was moving large sections of

piping to a new location when it overturned and struck the helper.

The crane's outriggers were set but matting was placed only under

the northwest outrigger pad. At the start of the construction project,

the manufacturing company cleared the site and had fill material

brought in. The site was originally swamp and large amounts of fill had

been brought in. (OSHA-2007-0066-0017.13).

Proposed Sec. 1926.1402, Ground conditions, is designed to prevent

this type of accident. Under that paragraph, care must be taken to

ensure that the surface on which a crane is operating is sufficiently

level and firm to support the crane in accordance with the

manufacturer's specifications. A contributing factor to this accident

may have been a lack of clarity regarding responsibility for adequate

ground conditions due to the fact that the employer who operated the

crane did not control the ground conditions on the property.

Section 1926.1402 would impose specific duties on both the entity

responsible for the project (the controlling entity) and the entity

operating the crane to ensure that the crane is adequately supported.

It places responsibility for ensuring that the ground conditions are

adequate on the controlling entity while also making the employer

operating the crane responsible for calling any deficiency to the

controlling entity's attention and having it corrected before using the

crane.

7. June 17, 2006: 1 fatality. A crane was being used on a barge to

install a dock in a waterway. Employees were preparing to move the

barge. A spud pipe, which anchored the barge, was being raised by the

barge-mounted crane when the hoisting cable broke, dropping the

headache ball and rigging onto one of the employees. (OSHA-2007-0066-

0017.3).

This type of accident can have various causes. An incorrectly

selected wire rope (one that has insufficient capacity), use of a wire

rope that is damaged or worn to the point where it needs to be

replaced, or two-blocking, in which the headache ball is forced against

the upper block, can each cause this type of failure. The provisions of

proposed Sec. Sec. 1926.1413 and 1414 on wire rope inspection,

selection, and installation are designed to ensure that appropriate

wire rope is installed, inspected and removed from service when its

continued use would be unsafe. Section 1926.1416, Operational aids,

contains provisions designed to protect against two-blocking.

8. July 13, 1999: 3 fatalities. Three employees were in a personnel

basket 280 feet above the ground. They were in the process of guiding a

large roof section, being lifted by another crane, into place. Winds

gusting to 27 miles per hour overloaded the crane holding the roof

section; that crane collapsed, striking the crane that was supporting

the personnel basket, causing the boom to fall. All three employees

received fatal crushing injuries. (OSHA-2007-0066-0017.4 & OSHA-2007-

0066-0018).

This type of accident would be prevented by compliance with

proposed Sec. 1926.1417(n), which requires the competent person in

charge of the operation to consider the effect of wind and other

adverse weather conditions on the equipment's stability and rated

capacity. In addition, proposed Sec. 1926.1431, Hoisting personnel,

requires that when wind speed (sustained or gust) exceeds 20 mph,

personnel are prohibited from being hoisted by a crane unless a

qualified person determines it is safe to do so.

9. November 7, 2005: 1 fatality. A construction worker was crushed

between the outrigger and the rotating superstructure of a truck crane.

He apparently tried to retrieve a level and a set of blueprints which

were laying on the horizontal member of one of the outriggers at the

same time the operator began to swing the boom. (OSHA-2007-0066-

0017.5).

This type of accident would be avoided by compliance with proposed

Sec. 1926.1424, Work area control. That section generally requires

that employers erect barriers to mark the area covered by the rotating

superstructure to warn workers of that danger zone. In addition,

employees who must work near equipment with a rotating superstructure

must be trained in the hazards involved. If an employee must enter the

marked area, the crane operator must be alerted and not rotate the

superstructure until the area is clear.

10. March 19, 2005: 2 fatalities and 1 injury. During steel

erection operations, a crane was lifting three steel beams to a parking

garage under construction. The crane tipped over and the boom

collapsed. The boom and attached beams struck concrete workers next to

the structure. Two were killed and one injured. The accident apparently

occurred as a result of overloading the crane. (OSHA-2007-0066-0017.6).

Overloading a crane can cause it to tip over. When it does, the

load or crane structure can strike and fatally injure workers who may

be some distance from the crane. Proposed Sec. 1926.1417, Operations,

includes provisions designed to prevent overloading. That section

prohibits the equipment from being operated in excess of its rated

capacity and includes procedures for ensuring that the weight of the

load is reliably determined and within the equipment's rated capacity.

The provisions on operator training and certification/qualification

will also help prevent this type of accident by ensuring that the

operator is sufficiently knowledgeable and skilled in recognizing

conditions that would overload the crane.

11. December 7, 2005. 1 fatality. Two cranes were being used to

lower a concrete beam across the river. During the lowering process,

the west side of the beam became lower than the east side. The

consequent shifting of the load's weight to the west side crane caused

that crane to tip over. The west end of the beam went into the river

and the east end fell on the bank and a support mat, causing a flag

person to be thrown into the beam. (OSHA-2007-0066-0017.7).

This type of accident would be prevented by compliance with

proposed Sec. 1926.1432, Multiple crane/derrick lifts. That section

specifies that when more than one crane will be supporting a load, the

operation must be performed in accordance with a plan developed by a

qualified person. The plan must be designed to ensure that the

requirements of this proposed standard will be met and must be reviewed

with all individuals who will be involved in the process. Moreover, the

lift must be supervised by an individual who qualifies as both a

competent person and a qualified person as defined in this standard.

In the type of scenario involved in this accident, a plan that

would comply with this requirement would, for example, include a

determination of the degree of level that is needed to be maintained in

order to prevent either crane from being overloaded. In addition, such

a plan would include a system of communications and a means of

monitoring the operation designed to ensure that the cranes' operation

was properly coordinated.

12. May 7, 2004: 1 fatality. An employee, a rigger/operator-in-

training, was in the upper cab of a 60-ton hydraulic boom truck crane

to set up and position the crane boom prior to a lift. The crane was

equipped with two hoists, a main line and auxiliary. The main hoist

line had a multi-sheave block and hook and the auxiliary line had a 285

pound ball and hook. When the employee was extending the hydraulic

boom, a two-block condition occurred with the auxiliary line ball

striking the auxiliary sheave head, knocking the sheave and ball from

the boom. The employee was struck in the head and killed by the falling

ball. (OSHA-2007-0066-0017.8).

This type of accident would be prevented by compliance with

proposed Sec. 1926.1416, Operational aids, which requires protection

against two-blocking. A hydraulic boom crane, if manufactured after

February 28, 1992, would have to be equipped with a device that automatically

prevents two-blocking.

Also, the operator-in-training in this case apparently did not

understand that extending a hydraulic boom would move the sheave head

toward the ball and could cause two-blocking. The proposed standard,

through proposed Sec. 1926.1427(a) and (f), would avoid having

inexperienced operators make this type of mistake by prohibiting an

operator-in-training from operating a crane without supervision and

without first having had enough training to enable the operator to

perform the assigned task safely.

13. April 26, 2006: One fatality. The deceased employee was part of

a framing crew which was in the process of installing sheathing for a

roof. A bundle of plywood sheathing was being hoisted by a crane to a

location on the roof. As the crane was positioning the bundle of

sheathing above its landing location, the load hoist on the crane free

spooled, causing an uncontrolled descent of the load. The employee was

under the load, preparing to position it to its landing spot, when the

load fell and crushed him. (OSHA-2007-0066-0017.9).

This type of accident would be prevented by compliance with Sec.

1926.1426, Free fall and controlled load lowering, which prohibits free

fall of the load line hoist and requires controlled load lowering when

an employee is directly under the load.

As discussed below in the Preliminary Economic Analysis, OSHA finds

that construction workers suffer 89 fatal injuries per year from the

types of equipment covered by this proposed standard. Of that number,

OSHA estimates that 53 would be avoided by compliance with the proposed

standard. In addition, OSHA estimates that the proposed standard would

prevent 155 non-fatal injuries each year. Based on all of the available

evidence and on the collective expertise of the members of C-DAC, OSHA

preliminarily finds that construction workers are faced with a

significant risk of death and injury resulting from equipment

operations and that the risk would be substantially reduced by

compliance with this proposed standard.

During the SBREFA process, several Small Entity Representatives

expressed concern that the C-DAC proposal was so long and complex that

small businesses would have difficulty understanding it and complying

with it. The SBREFA Panel recommended that OSHA solicit public comment

on how the rule could be simplified and made easier to understand

without creating ambiguities. OSHA welcomes public comment on this

issue.

III. The SBREFA Process

Before proceeding with a proposed rule based on the C-DAC Consensus

Document, OSHA was required to comply with the Small Business

Regulatory Enforcement Fairness Act of 1996, 5 U.S.C. 601 et seq.

(SBREFA). This required OSHA to draft an initial regulatory flexibility

analysis that would evaluate the potential impact of the rule on small

entities (defined as small businesses, small governmental units, and

small nonprofit organizations) and identify the type of small entities

that might be affected by the rule. In accordance with SBREFA, OSHA

then convened a Small Business Advocacy Review Panel ("Panel")

composed of representatives of OSHA, the Office of Management and

Budget, and the Office of Advocacy of the Small Business

Administration. Individuals who were representative of affected small

entities (Small Entity Representatives, or "SERs") were then

identified for the purpose of obtaining advice and recommendations from

those individuals about the potential impacts of the proposed rule.

OSHA provided the SERs with the C-DAC consensus document and the

draft regulatory flexibility analysis and afforded them the opportunity

to submit written comments on those documents. The Agency also drafted

questions asking them their views on the specific aspects of the C-DAC

document it thought would be of most concern to small entities.

The Panel conducted two conference calls with the SERs in which the

SERs presented their views on various issues. After reviewing the SERs'

oral and written comments, on October 17, 2006, the Panel submitted its

report summarizing the requirements of the C-DAC proposal, the comments

received from the SERs, and presenting its findings and

recommendations. (OSHA-S030A-2006-0664-0019). In its findings and

recommendations, the Panel identified issues that it believed needed

particular attention and analysis in the proposal or for which it

believed OSHA should explicitly solicit public comment.

In the discussion that follows, OSHA addresses each of the Panel's

findings and recommendations in the section pertaining to the issue

involved. Table 4 summarizes the Panel's recommendations and the

portions of this preamble in which they are discussed.

Table 4--SBREFA Panel Recommendations and OSHA Responses

------------------------------------------------------------------------

SBREFA panel recommendation OSHA response

------------------------------------------------------------------------

The Panel recommends that OSHA provide See the Preliminary Economic

full documentation for how it Analysis (PEA), in section

estimated the number of affected small V.B. of this Federal Register

entities and all other calculations notice.

and estimates provided in the PIRFA.

The Panel recommends that OSHA See the Preliminary Economic

reexamine its estimate of crane use in Analysis (PEA), in section

home building, the coverage of crane V.B. of this Federal Register

trucks used for loading and unloading, notice.

and the estimates of the number of

jobs per crane. Changes in these

estimates should be incorporated into

the estimates of costs and economic

impacts.

The Panel recommends that OSHA review See the Preliminary Economic

its estimates for the direct costs of Analysis (PEA), in section

operator certification and seek V.B. of this Federal Register

comment on these cost estimates. notice.

The Panel recommends that OSHA See the Preliminary Economic

carefully examine certain types of Analysis (PEA), in section

impact that could result from an V.B. of this Federal Register

operator certification requirement, notice.

including reports of substantial

increases in the wages of operators;

the possibility of increased market

power for firms renting out cranes;

and loss of jobs for existing

operators due to language, literacy,

or knowledge problems; and seek

comment on these types of impacts.

The Panel recommends that OSHA consider See the Preliminary Economic

studying the impacts of the Analysis (PEA), in section

implementation of operator V.B. of this Federal Register

certification in California. notice.

The Panel recommends that OSHA See the Preliminary Economic

reexamine its estimates for the amount Analysis (PEA), in section

of time required to assess ground V.B. of this Federal Register

conditions, the number of persons notice.

involved in the assessment, and the

amount of coordination involved;

clarify the extent to which such

assessments are currently being

conducted and what OSHA estimates as

new costs for this rule represent; and

seek comments on OSHA's cost estimates.

The Panel recommends that OSHA The Agency describes the

carefully review the documentation documentation requirements,

requirements of the standard, along with cost estimates, in

including documentation that employers the section of this Preamble

may consider it prudent to maintain; entitled "OMB Review Under

estimate the costs of such the Paperwork Reduction Act of

requirements; seek ways of minimizing 1995."

these costs consistent with the goals

of the OSH Act; and solicit comment on

these costs and ways of minimizing

these costs.

The Panel recommends that OSHA examine As explained in the discussion

whether the inspection requirements of of Sec. 1926.1412,

the proposed rule require procedures Inspections, OSHA's current

not normally conducted currently, such standard at 29 CFR 1926.550

as lowering and fully extending the requires inspections each time

boom before the crane can be used and the equipment is used as well

removing non-hinged inspection plates as thorough annual

during the shift inspection, estimate inspections. In addition,

the costs of any such requirements, national consensus standards

and seek comment on these issues. that are incorporated by

reference include additional

inspection requirements. This

proposal would list the

inspection requirements in one

place rather than rely on

incorporated consensus

standards. OSHA does not

believe this proposed standard

imposes significant new

requirements for inspections.

Section 1926.1413(a)

explicitly says that booming

down is not required for shift

(and therefore monthly)

inspections.

Similarly, OSHA does not

believe that inspection of any

of those items would require

removal of non-hinged

inspection plates. In the

discussion of proposed Sec.

1926.1412, OSHA requests

public comment on these

points.

The Panel recommends that OSHA consider Currently, Subpart N, at 29 CFR

the costs of meeting the requirements 1926.550(a)(2), requires load

for original load charts and full charts, so that is not a new

manuals, and solicit comments on such cost. Subpart N does not

costs. require manuals. OSHA believes

that most crane owners and

operators have and maintain

crane manuals, which contain

the load charts and other

critical technical information

about crane operations and

maintenance. The Agency

believes that the cost of

obtaining a copy of a manual

should be modest and solicits